Request our manufacturing capability

Capabilities

Single Layer PCB

What Is Single Layer PCB?

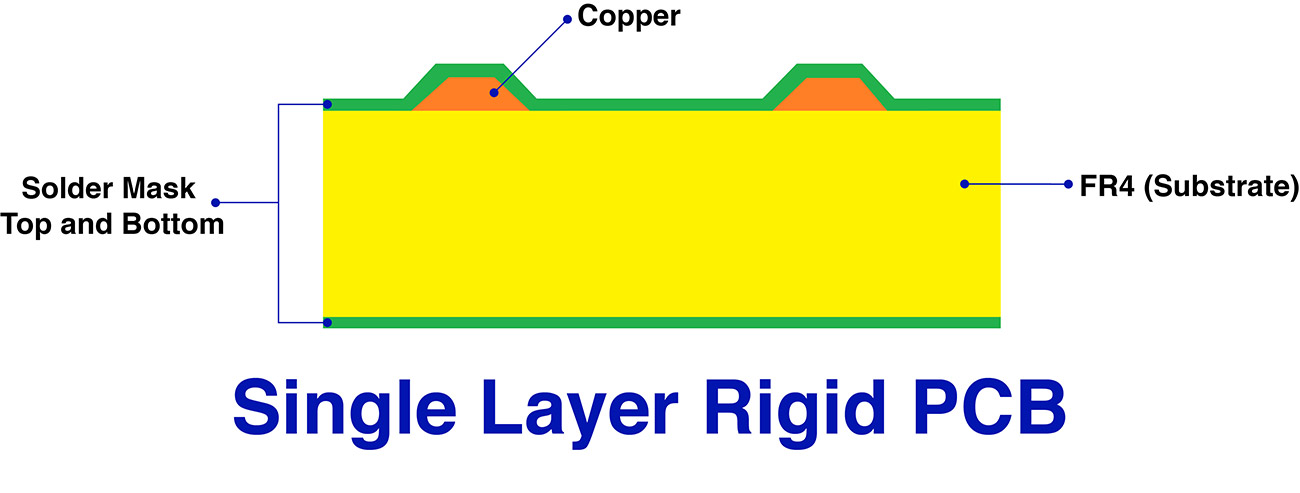

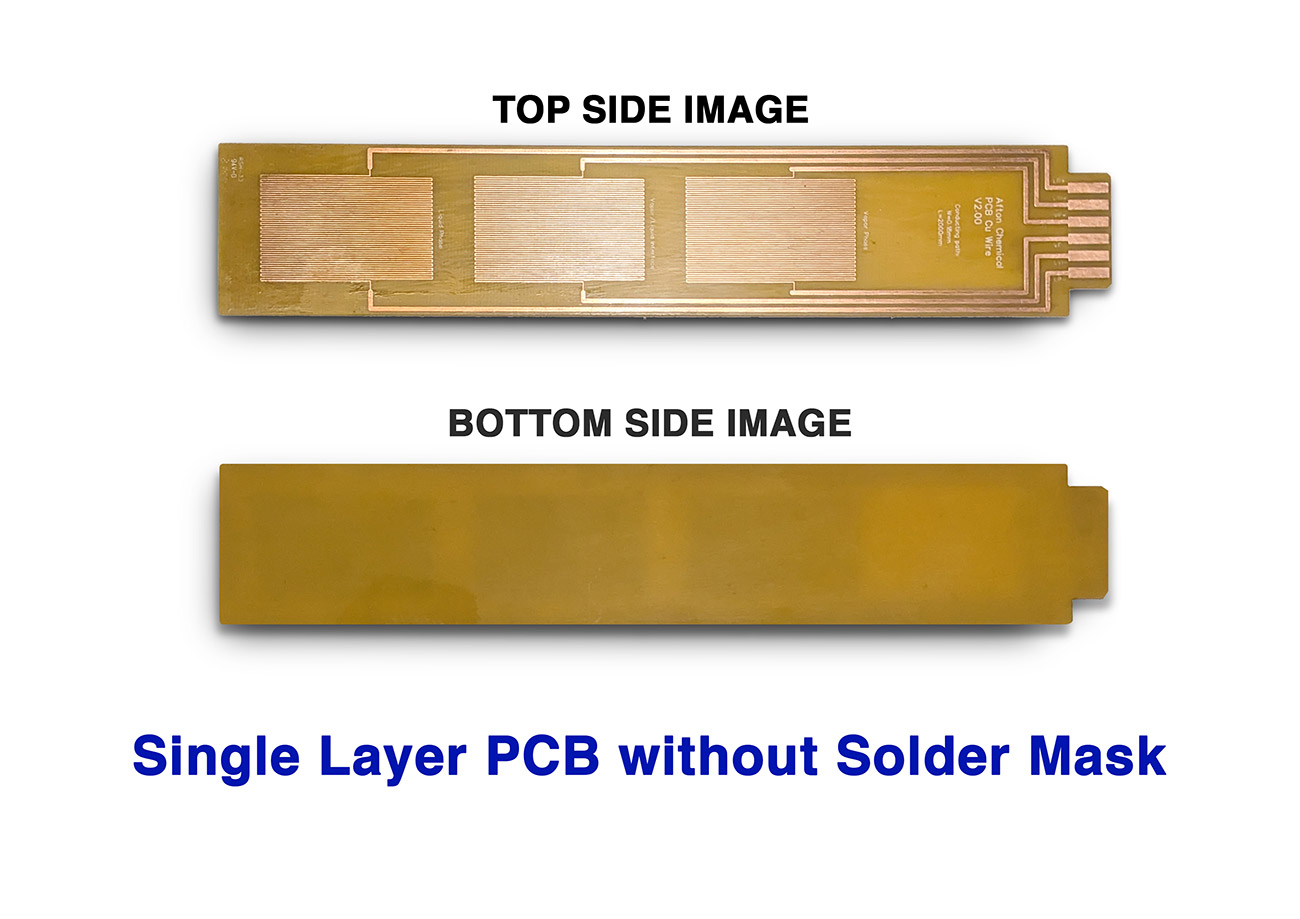

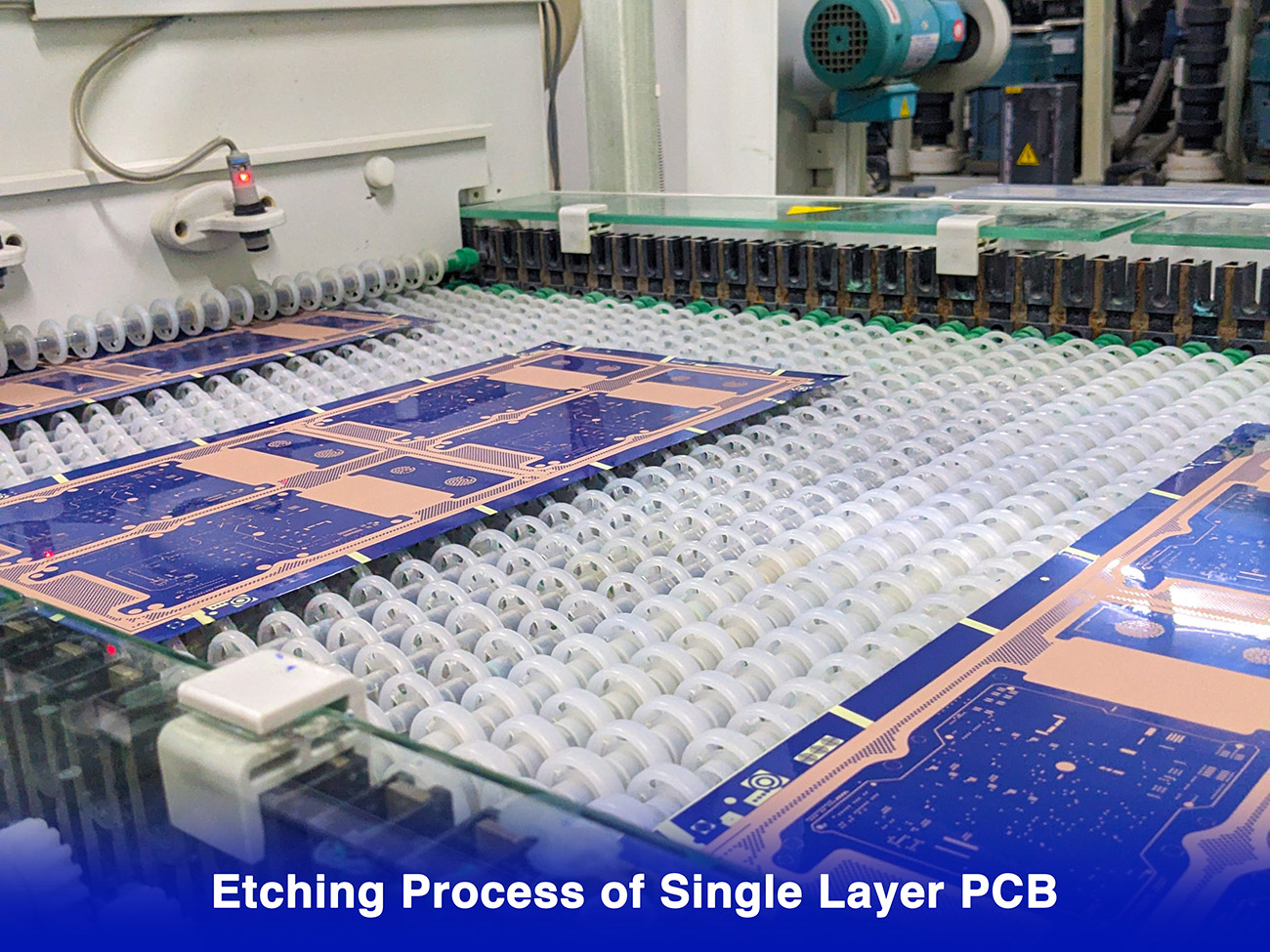

The Single Layer PCB Structure

Substrate (Base Material)

Substrate is a base material made from epoxy resin fiber glass, which helps as a mechanical support for rigid PCB’s, current insulation and helps keep all copper layer separate.

Copper Layer

Solder Mask

A polymer layer that is usually green, also it comes in other colors. It protects the copper traces from oxidation and prevents solder bridges between solder pads during the soldering process.

Silkscreen

A non-conductive ink, often white, but can also be yellow, black, or other colors. The purpose for printing silkscreen on PCB’s is to provide reference designators, UL & Date code markings and other information to help during assembly and troubleshooting.

Stackup of Single Layer PCB's

- Signal Integrity

- EMI/EMC Considerations

- Power Distribution

- Component Placement and Routing

- Thermal Management

- Reliability and Long-term Performance

- Mechanical Strength and Durability

- Manufacturability and Cost Constraints

Applications & industries of Single Layer PCBs

- Consumer Electronics

- Automotive Electronics

- Home Appliances

- Educational and Prototyping Purposes

- Communication Devices

- Audio Devices

- Toys and Gadgets

- Lighting Solutions

- Office Equipment

Single-layer PCBs are still essential in many applications where easy application, cost, and fast response are important considerations. Engineers and producers must comprehend their applications, structure, and stack-up details. By using their strengths through thoughtful design and consideration, one can successfully utilize the advantages of single-layer PCBs in different applications including, home appliances, educational and prototyping purposes.

We welcome you to send a custom design/manufacturing quote for your current project to our experienced sales engineers at [email protected] and [email protected]. We are committed to fulfill your critical or standard design & manufacturing requirement with our IPC Certified Workmanship. And to ensure your electronic initiatives comes to a success.