Request our manufacturing capability

Capabilities

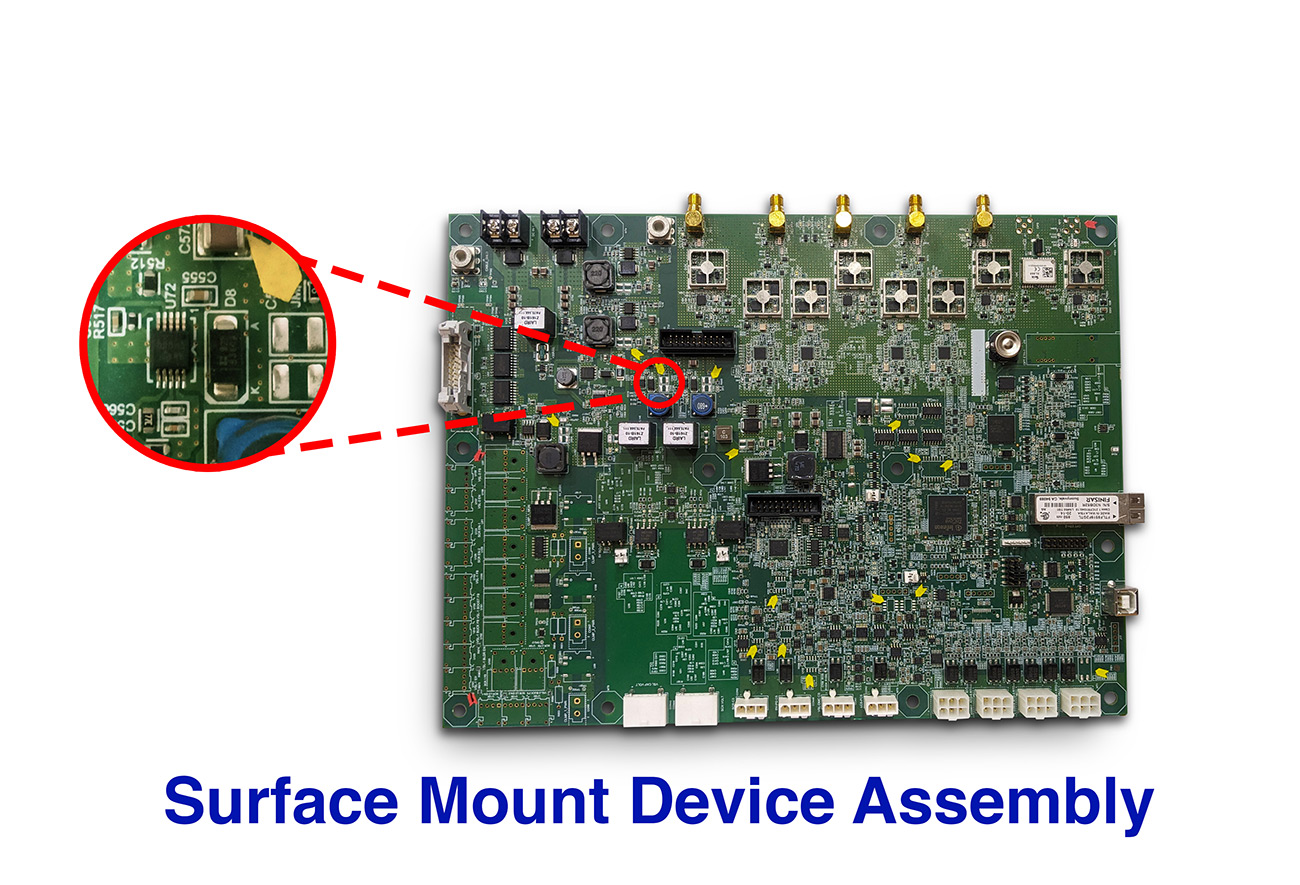

SMT PCB Assembly in the USA and Canada

SMT PCB Assembly

With the help of SMT or surface mount technology parts, it has become easy to assemble circuit boards with small surface area surface areas and dimensions PCB’s. All modern technology consists of SMT parts, as all the components are available in small sizes and require small footprints compared to the through-hole parts drilled into the PCBs. They are easy to solder, and no drilling is required.

Blind Buried Circuits has been a key player in providing quality PCB assemblies in the USA and Canada with quick turn lead times. We have been assembling the boards for a long time, and most of our customers take our one-stop-shop service to complete the boards quickly. To learn more about our capabilities or request a quotation, please fill out our quote form and get a quick quote for your SMT PCB assembly!

Understanding SMT Sizes and SMD Component Sizes

When it comes to SMT sizes or packages of SMD components, the variety of SMD component sizes plays a significant role in how efficiently the components are assembled onto the PCBs.

At Blind Buried Circuits, we assemble an extensive range of SMD package sizes to meet our customers’ specific needs. Whether it’s micro components like 01005, 0201, or larger packages, our pick & place equipment ensures precise placement and soldering to meet IPC A 610 and good wetting on the boards to enhance design outputs and performance.

The Importance of SMT PCB Board Design in High-Quality Manufacturing

Designing an SMT PCB board requires an understanding of the limitations and possibilities provided by SMT SMD components. Our team works with a wide range of SMD components, ensuring compatibility with various designs while maintaining high reliability. Our expertise in smt electronic components allows us to assist customers in optimizing their designs for mass production, reducing costs while improving overall performance.

How Does SMT Work?

To understand SMT, it is a process that assembles the electronic components on the surface of the PCB. Usually, SMT components are small, so they are assembled by automatic pick-and-place machines, which are programmed to assemble the components precisely and at the exact location. With the help of automated processes, most of the nanotechnology is manufactured with the help of SMT parts. It takes less surface than through holes (TH) parts and is very light in weight, which makes it an ideal choice for nano designs.

It is also considered a faster process as automated machines perform the assembly process, and no manual soldering is required. To know more about what technology can help you in your upcoming or current projects, please get in touch with our engineering team at [email protected]

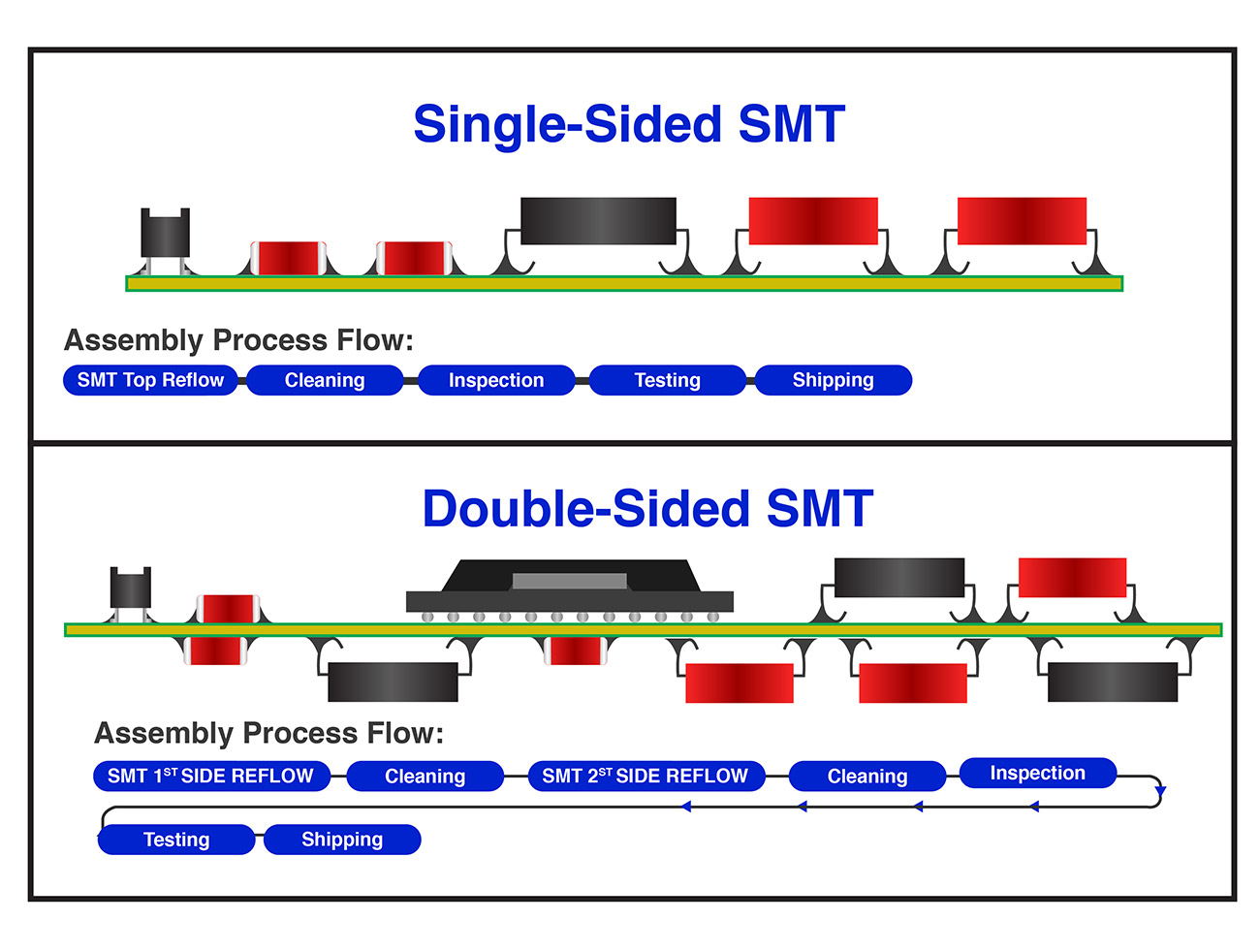

Assembly Process of Surface Mount Technology (SMT)

The following is the SMT assembly process that Blind Buried Circuits follows to provide quality PCB assemblies.

Application Of Solder Paste On the Bare PCBs

Due to the tiny component footprints, it is not possible to do soldering by hand or by solder wire. Due to this, we apply solder paste on the surface of the PCB where the components must connect. The paste consists of solder particles and flux to better connect the bare board and components. To apply the solder paste on the bare boards, most assemblers, like Blind Buried Circuits, use a frame or foil stencil and an automated squeegee machine to print solder paste on the bare boards with alignment. The electrical connections are formed once the heat is provided to the solder paste.

Solder Paste Printing: Essential for Reliable Circuit Assembly

One of the key processes in SMT manufacturing is the precise application of solder paste. Solder paste printing ensures a clean and reliable connection between the surface mount components and the SMT PCB board. At Blind Buried Circuits, we use advanced stencil printing technologies to achieve high precision in this crucial step of the assembly process. This method allows us to meet the demanding standards of industries such as medical devices and telecommunications.

Component Placement Through Pick-and Place Machines

The component placement is the next process after applying solder paste on bare PCBs. In this process, the pick-and-place machines carefully place the discrete components such as 01005, 0201, and 0402 on the bare PCBs. Usually, the discrete parts are supplied in tape, and reels, which helps the pick and place machine vacuum nozzle to pick the part and place it on the bare PCB with an accurate position. The component’s packaging may vary based on the type of component and the distributor selected. But it is always recommended that all the discrete components must be supplied in tape and reel.

For the prototypes, a minimum of 6 inches of cut tape is required in total length to feed into the pick and place feeder.

Component Soldering In Reflow Oven

All the SMT components are soldered by baking them in the reflow oven. It consists of various process that makes the component fully attached to the bare PCBs. It starts by preheating the circuit board and then taking it to a certain temperature where the solder joints form. It is a controlled process ensuring the temperature doesn’t impact the connectivity and components. The temperature may vary depending on the assembly process. RoHS assemblies usually keep temperatures high, so the Hi TG PCB material is recommended for bare boards. The reflow oven temperature usually operates at a lower scale for non-RoHS assemblies. After the reflow process, the component’s joints get cooled to make it strong.

For the prototypes, a minimum of 6″ cut tape is required in total length to feed into the pick and place feeder.

Final Quality Assurance (QA) Inspection of Assembled Boards

At Blind Buried Circuits, we do a QA inspection on each step, and after the reflow process, our dedicated QA inspection team checks all the solder joints by automatic optical inspection (AOI) and visual inspection. It helps prevent soldering issues and identify them before shipping the boards to our customers.

High-Quality Circuit Board Assembly with Blind Buried Circuits

At Blind Buried Circuits Inc, we specialize in complete turnkey circuit board assembly solutions for our customers in the USA and Canada. Our team focuses on providing high-quality printed circuit assemblies that meet industry standards across various sectors. Whether you need small prototype batches or large-scale production, our focus on SMT manufacturing ensures that every board we deliver is of the highest quality and precision.

Blind Buried Circuits Inc, SMT Assembly Capabilities

Being an experienced and leading Full Turnkey service provider, Blind Buried Circuits equips multiple SMT assembly lines, which assemble all types of component packages daily, including 01005, 0201, 0402, and other discrete components. We perform AOI, X-ray inspection for BGAs, on-demand In-circuit, and functional testing for our customers all over the United States and Canada.

The Industries We Serve

We serve various sectors throughout the United States and Canada, including our customers in Wisconsin, Massachusetts, New York, Ohio, Washington DC, and Texas. Following is the list of industries we are serving and making all the complex assemblies into reality for them.

- Medical Industry

- Telecom and Communication Industry

- Commercial and Industrial Equipment

- Traffic and Transportation

- Marine and Defense Agencies

- Energy and Utilities sector

Get A Quick Quote For Your SMT Assemblies

We have an easy and detailed quoting process, fill out our quote form and upload your Gerber RS-274x and xls BOM file along with the quantity and lead time you want us to assemble. You can also directly reach out to our sales team at [email protected] to get a quote as soon as possible.