FLEX PCB Manufacturer

FLEX PCB – BLIND BURIED CIRCUITS

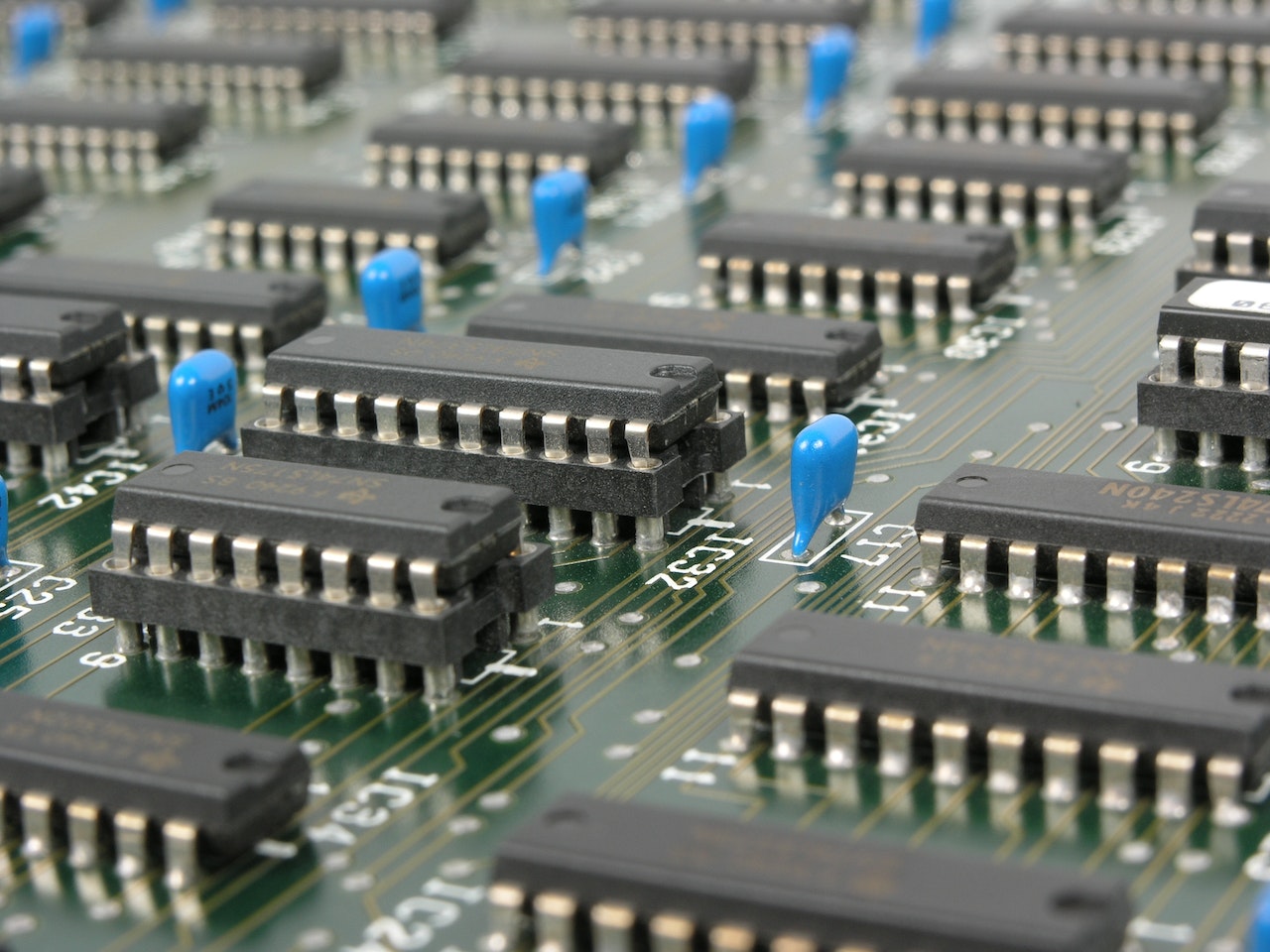

Blind Buried Circuits offers a wide range of Flexible printed circuit boards or FPCBS manufacturing and Flex PCB assembly in USA, with various flex PCB material types and coverlay options. Flex PCBs are similar to rigid flex PCBs, but when it comes to the difference between flexible PCB vs rigid PCBs, Flex PCBs are getting popular due to their flex PCB design pattern and ease of fitting in any device where Rigid PCBs cannot be used.

While many designers get worried while designing about the manufacturing capabilities of their suppliers, we encourage our customers to contact us when designing the flex circuit and considering flexible PCB material properties so our experienced engineering team can guide them over their design parameters to achieve maximum efficiency.

WHAT IS A FLEX PCB?

Flex PCBs are electronic circuits designed to make them flexible, bendable, and capable of fitting into tight spaces. But to maintain the tight spaces, the flex PCB design requires flexible PCB material suppliers, flexible PCB stackup, tight tolerances and special process treatments.

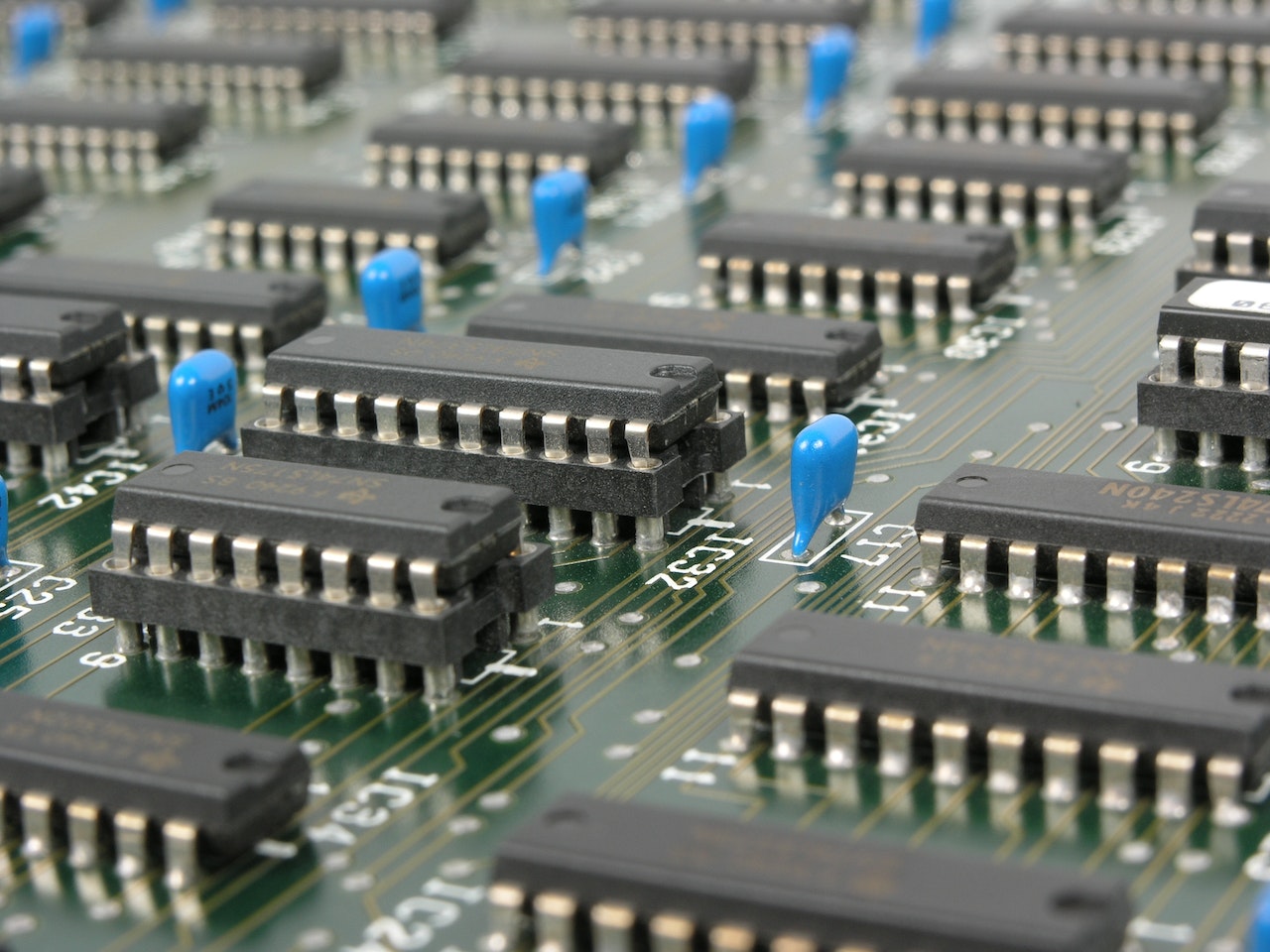

OUR MANUFACTURING CAPABILITIES

Blind Buried Circuits flexible PCB fabrication manufacturing capabilities include the following:

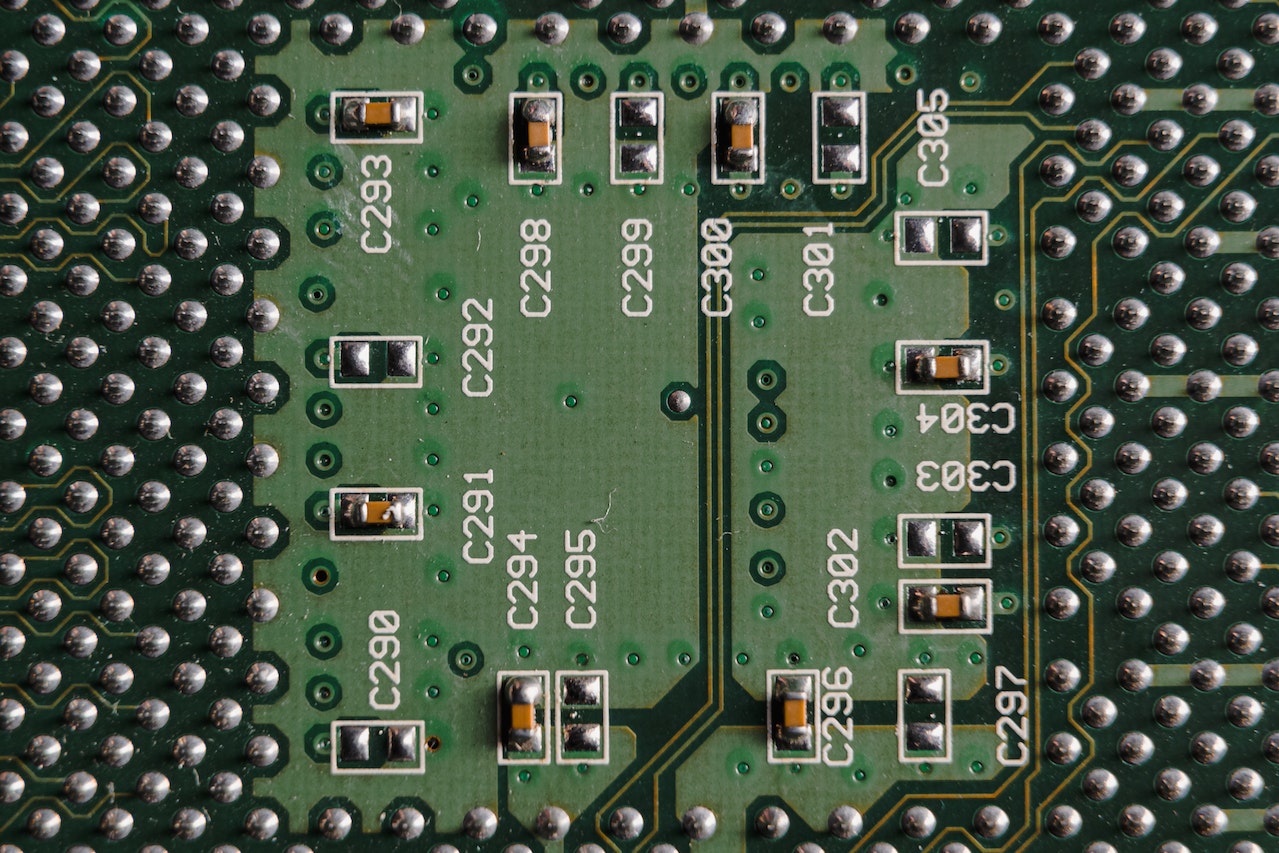

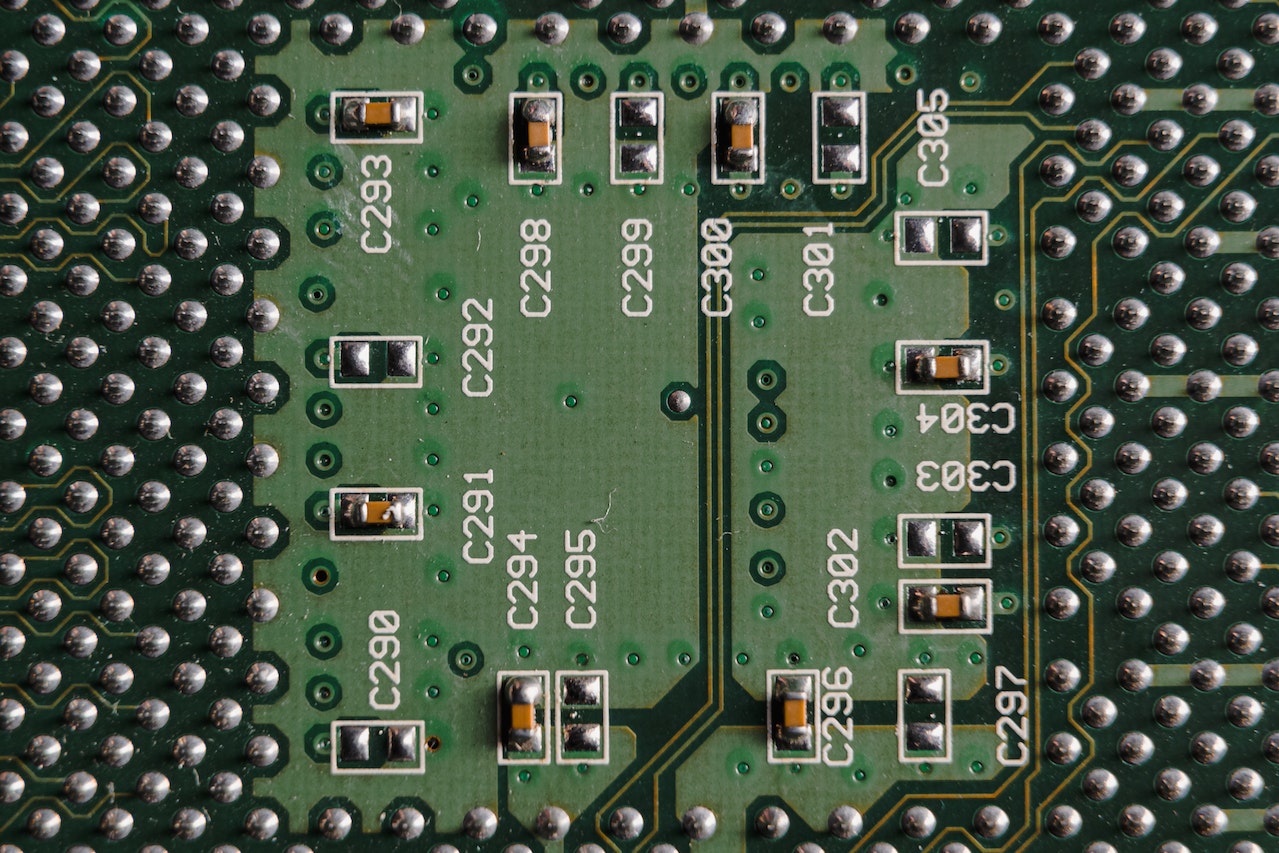

| Flexible PCB Material Selection | |

|---|---|

| polyimide flexible PCB Subtract (Thickness) | 12 µm (0.0005”), 15 µm (0.005”), 25 µm (0.001”), 50 µm (0.002”), 75 µm (0.003”) |

| Copper Clad (Thickness) | 9 µm (0.25 oz), 12 µm (0.33 oz), 17 µm (0.5 oz), 35 µm (1 oz), 70 µm (2 oz) |

| Copper Foils (Rolled-Annealed) | Polyester, Polyimide, PIC (Photo Imageable Cover Coat), LPI (Liquid Photo Imageable) |

| Stiffeners or flexible PCB insulation | Polyimide, Metal, FR-4, or customer supplied |

| Thermo-Bond Adhesives | Phenolic Butyral, Acrylic, Modified Epoxy |

| Surface Finishes | Immersion Tin, Entek 106A, ENIG (Electroless Nickel Immersion Gold), Hard Gold, Electrolytic Soft Bondable Gold, Tin/Lead Plating, and Hot Air Solder Leveling |

| Process Tolerances and Capabilities | |

|---|---|

| Minimum Trace/Space | 0.0015”/0.002” for 0.33 oz copper 0.002”/0.0025” for 0.5 oz copper 0.003”/0.0035” for 1 oz copper |

| Minimum Via Hole Dia (Before Plating) | 0.006” (NC Drill) 0.002” (UV Laser) |

| Minimum Blind Via Dia (Before Plating) | 0.004” (UV Laser) |

| Trace to Edge Distance | 0.010” for NC Routing 0.008” for Die Punch method 0.001” for UV Laser |

| Trace to Edge Tolerance | 0.005” for NC Routing 0.003” for Die Punch method 0.001” for UV Laser |

| Cover Layer Aperture Positional Tolerance | 0.005” for Cover Film 0.002” for LPI and PIC 0.001” for Laser Ablation |

WHAT ARE THE BENEFITS OF FLEX PCBs?

All types of printed circuit boards consist of various benefits and flexible PCB application, whether making a wearable product or a phone; all types of PCBs play a significant role in product development. But when it comes to traditional Rigid PCBs, they are used for the very specific area where bendability doesn’t matter at all. But regarding wearable products like smartwatches, Rigid PCBs are useless. That’s when Flex PCB helps in completing the idea into the product. The following are the significant benefits of PCB Flexible or FPCBs:

- Reduced flexible PCB board thickness and weight: When it comes to ideal application, the designers always focus on low weight and thickness, attracting consumers to carry it easily. This is where Flexible PCBs play a vital role; the flexible PCB thickness is much thinner and lighter in weight than Rigid PCBs. The most common example of flex circuits is flexible PCB connectors.

- Improved flexibility: With the products like flexible smartphones and wearable electronic items, the circuit needs to be in a specific shape to maintain the product’s form factor. Flex PCB board can be bent and flexed in any direction by considering and calculating the flex factor. Contact us if you have any questions regarding the flex factors for your PCB design or flexible PCB design guidelines.

We cater several Flexible Circuit Board markets

Consumer Electronics

Medical Devices

Aerospace and Defense

Automotive Industry

Industrial Applications

Our flexible PCBs are implanted in industrial applications such as robotics, control systems, and sensors.

Don’t hesitate to get in touch with our sales team at [email protected] if you have any questions or concerns regarding flexible PCB prototype and production.

frequently Asked Questions

To avoid manufacturing and DFM issues in flex circuits:

- Avoid Plated Holes in the bend areas, “PTH Vias in bending regions can cause stress and failure.”

- Careful Placement of Vias near stiffeners, “Vias should not be placed just off the edge of stiffeners to prevent cracking.”

- Dynamic Flexing in applications with repeated bending, “Ensure Vias are not in flexing areas to avoid rapid cracking.”

- Teardrop Vias, “This helps to reduce stress on bendable area to Annular ring.”

- Add Tabs or Anchors to Vias, “This will help prevent peeling.”

- Use Curved Traces, “Avoid Trace with Sharp Corners as this reduces the chances of broken trace in bendable area.”

- Stagger Traces in Multi-layer Designs, “For Flex Circuits with 2 or more Layers, use stagger traces method on the top and bottom layers.”

The most common method to maintain the flex bendability with ground planes Is to design the copper planes as in hatching pattern, by ensuring to keep minimum 0.15” wide signals with 0.25” spacing.

Based on the thickness of coverlay (0.5mils), the minimum webbing width required is 4 mils. However, we can accommodate the Soldermask resist on those Area to prevent Solder short/wick during assembly.

As per our capabilities, we offer FR4, Metal (Aluminium & stainless steel), Polyimide (PI) stiffeners.