PCB MANUFACTURER & ASSEMBLY MICHIGAN

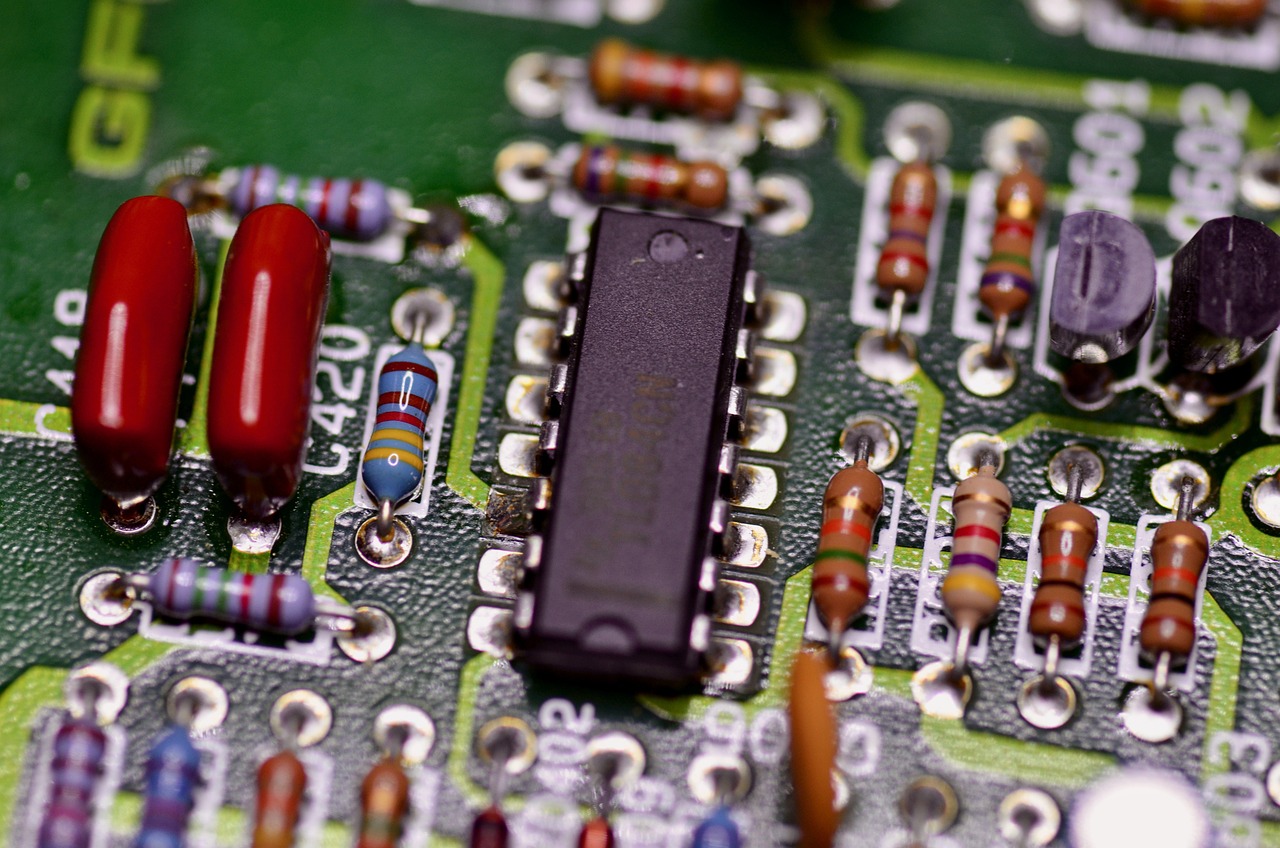

Michigan, USA Premier Manufacturer of Blind Buried Circuits via PCBs

Blind Buried Circuits, a PCB manufacturer in Michigan, USA, loves to go where others dare not. We understand the hardships of our customers that they face when seeking a provider with experience in an extensive range of industries and who is prepared to take on their technical design challenges. Blind Buried Circuits not only offers admirable design expertise. We also initiate cost-saving solutions that benefit our customers significantly. Our team welcomes every opportunity to promote them on their present projects.

As a globally honored PCB Manufacturer in Michigan, USA, our design team and application engineers offer diverse decades of combined industry expertise. That permits Blind Buried Circuits to offer customers high-caliber PCB design services and focused overall support.

PCB Manufacturing and Assembly Michigan, USA

Our Michigan, USA-based manufacturing facilities permit us to offer top-notch quality and pocket-friendly prices.Our value-added service and customer support:

- Testing Services

- Single-sided Boards

- Double-sided Boards

- Multilayered Boards

- PTH (Plated Through Hole), SMT (Surface Mount Technology), mixed assembly services

- Box Build Services

- Rigid PCBs

- Design Consultation, Design for Manufacturing, Optimization

- Flex PCBs

- Rigid-flex PCBs

- Prototype and Full Production (we support high-mix low-volume and low-mix high-volume programs)

Our unparalleled business model permits us to effectively serve our best services to our customers across the globe.

Operating out of Michigan, USA, we have established ourselves to provide our customers with impressive quality and support. Our prices are pocket-friendly due to our facilities being local. Call us today for all your printed circuit board needs and requirements. Enjoy a matchless design and manufacturing experience. We are strongly dedicated to delivering high-quality and cost-effective solutions.

PCB Assembly Michigan, USA

Our PCB Assembly Michigan, USA, aims to provide our customers with high-quality services at competitive prices. We are ready to understand all programs from our customers, whether they are high or low volume. We have program managers, a customer support team, and a management team. Our assembly efficiency offers:

- 100k and 10K Clean Rooms

- Reliability Laboratories

- Complete SMT Lines

- Dedicated Workshops for High-Volume Programs

- Modern Electronic Workshops

- Testing Centers

We produce complete box builds, sub-assemblies, or assembled product modules for our customers.We also specialize in testing services, including software, functional, and hardware testing. To understand our customers’ test requirements, we also design specialized custom test equipment.

PCB manufacturer Michigan, USA, offers our customers full turn-key assembly, where we handle the whole project. We manufacture the printed circuit board, procure the elements, and provide the labor for assembling them. Our customers have peace of mind that they do not have to follow up with various vendors.We also encourage customers who want to provide their own elements for assembly.We fabricate printed circuit boards and supply the labor for assembling their boards.

Rigid and Rigid-Flex PCB Manufacturer Michigan, USA

Blind Buried Circuits, a Rigid and Rigid-flex PCB manufacturer in Michigan, USA, has provided medical and aerospace industries with various printed circuit boards. Our rigid and rigid-flex printed circuit board combination provides the best and most high-quality printed circuit boards. Our circuits offer the best quality control and higher element density. With our expertly designed printed circuit boards, we can offer flexible parts for areas that have space limitations and rigid parts for extra support. Customers use our rigid and rigid-flex printed circuit boards for reasons related to:

- Flexible Design Options

- Connection Reliability

- Package Weight and Size Reduction

- Lower Parts Count

- High-Density Applications

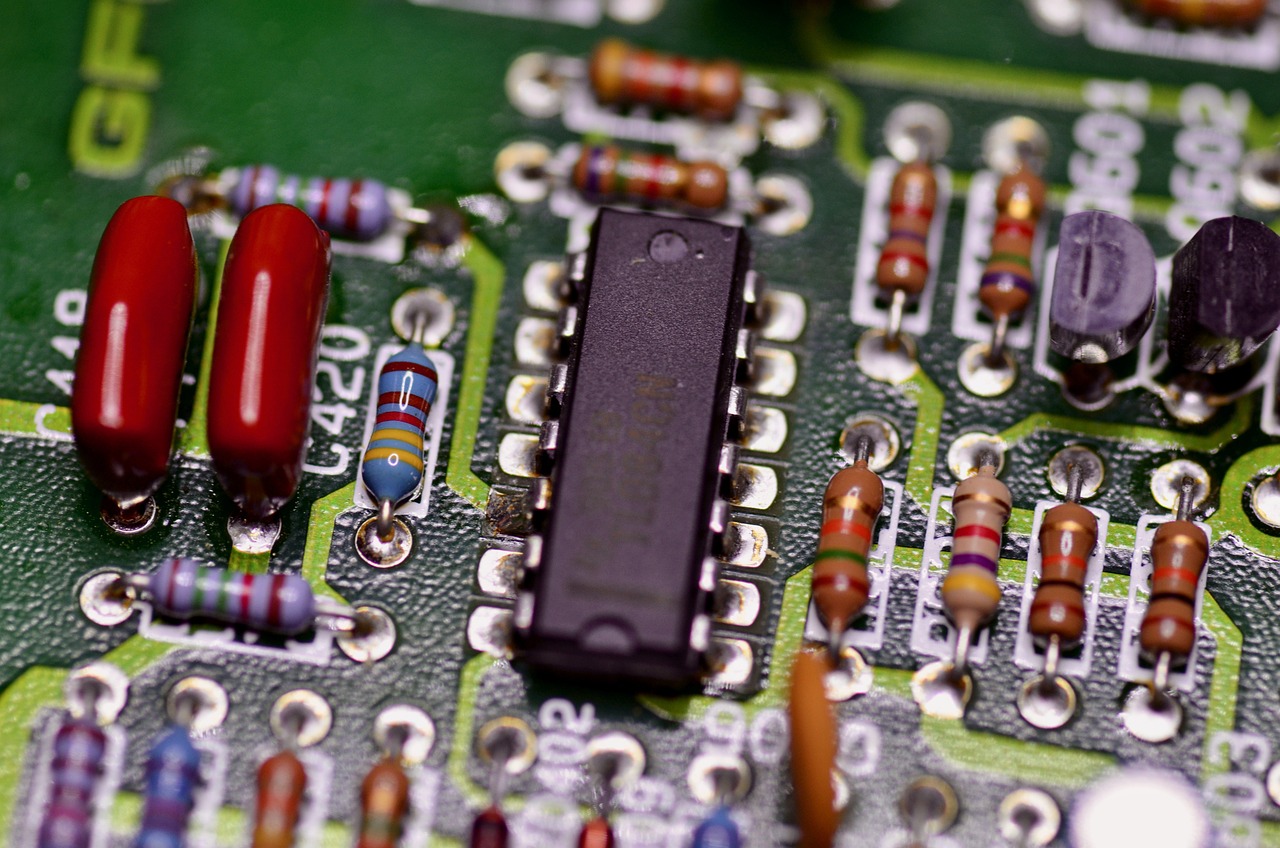

HDI PCB Manufacturer Michigan, USA

With the international marketplace becoming highly demanding, Blind Buried Circuits, HDI PCB Michigan, USA, constantly exceeds the capabilities and technologies of our competitors. We are the industry masters in providing High-Density Interconnects for a wide range of industries.

Our team uses CO2 and laser drilling to initiate micro vias in our HDI-printed circuit boards for making blind vias. We use solder copper-filled, buried vias, via-in-pads, and thin spaces and tracks. The team manufactures HDI circuit boards conforming to UL criteria and RoHS directives.

Our Capabilities for HDI circuit boards are as follows:

Features | Capabilities |

Copper Thickness | 5 microns |

Core Dielectric Thickness | 12 microns (Minimum) |

Microvia Diameter | 25 microns (Minimum) |

Blind Microvia Aspect Ratio | 1.2:1 (Depth to Diameter) |

Via fill | Solid Copper |

Track Width / Spacing | 19 microns / 19 microns |

Blind and Buried Via Construction Technique | Sequential Build |

Contact us today to learn more about how we can help your company with highly complex HDI-printed circuit boards.

Along with that, we also provide design assistance for the following:

- Highly Complex Configurations

- Controlled Impedance

- Three to Eight-Layer Combinations

- Interconnection Reduction

We are experts in flexible printed circuit boards and take on the most complex design challenges. By combining flex PCBs with rigid boards, we can design rigid-flex circuits to understand configurations that others would consider unimaginable and highly complex. We offer our customers highly smooth designs while decreasing the package weight and size at the same time.

How to Get a Quote

You have to fill out our RFQ (Request for Quote) form by submitting all the specifications of your design along with the files to get a rapid quotation!

Important Note: Please submit the Gerber File in 274x format. The BOM files should be in Excel format only. The BOM must include reference designators, quantity, description, and manufacturing part number. For urgent orders, reach out to us at [email protected] or call us at +1 312 620 6992.