Request our manufacturing capability

Capabilities

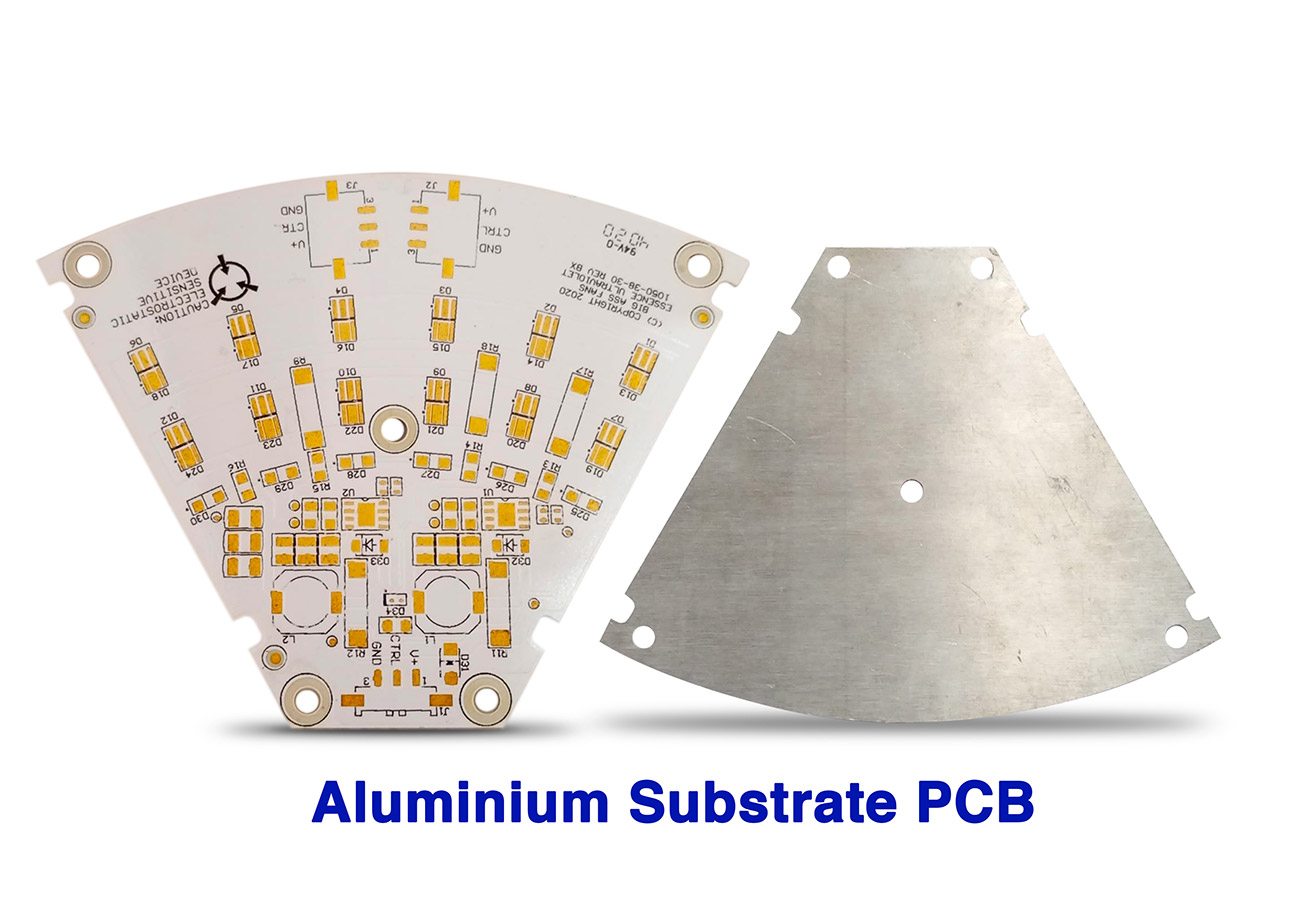

Metal Core PCBs

Introduction to Metal Core PCBs

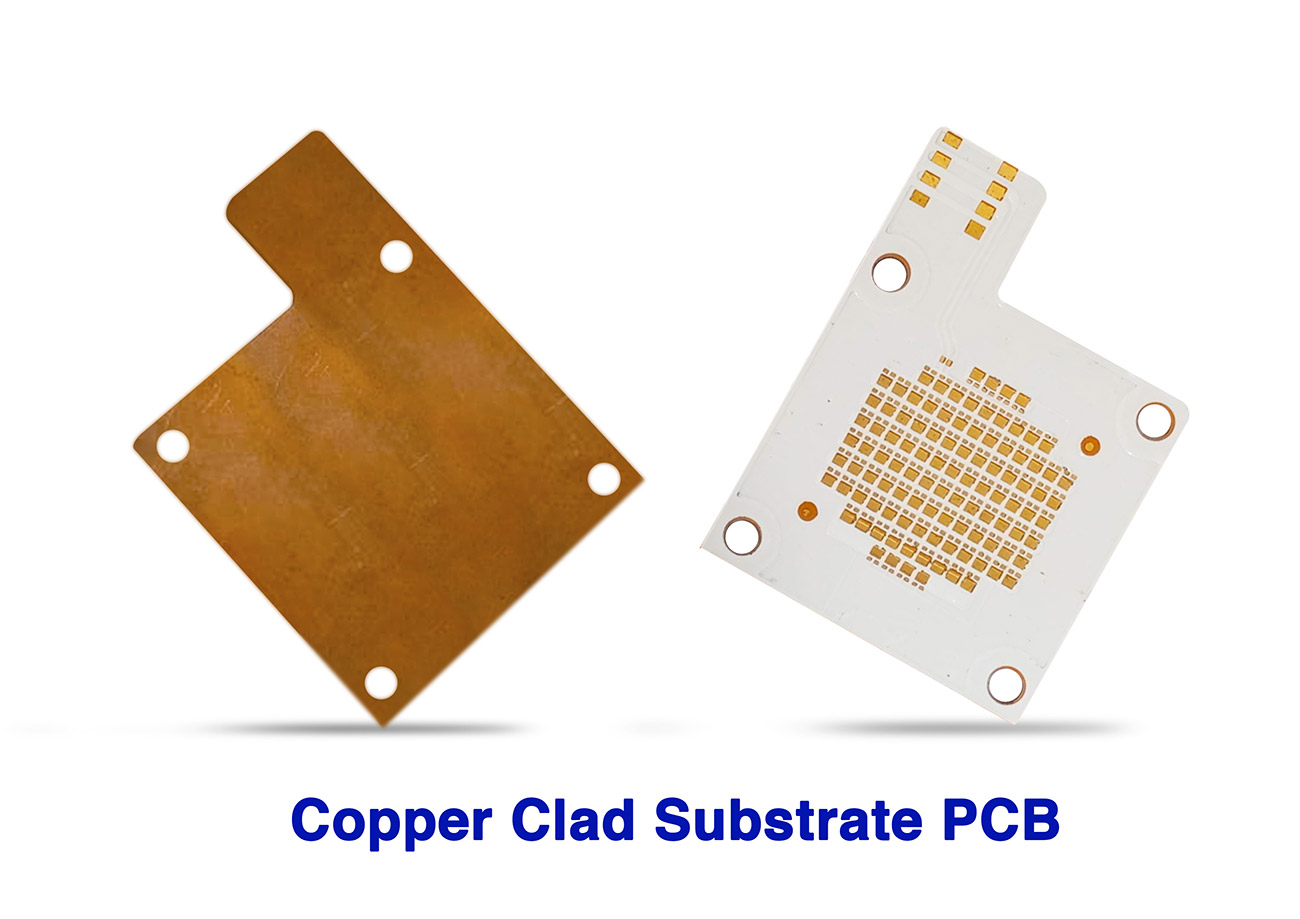

Metal Core PCBs, or MCPCBs, consist of a metal core, such as an aluminum pcb substrate or copper clad pcb substrate. The metal core pcb material (substrates) in PCB works as a thermal resistivity for electronic devices just like an LED Circuit. MCPCBs are specially manufactured for high-power applications and environments with high temperatures, providing thermal management capabilities. Blind Buried Circuits Inc. delivers all types of metal-core PCB manufacture to various industries.

Advantages of Metal Core PCBs

MCPCBs improve the reliability of electronic applications. The metal core of MCPCBs offers multiple advantages over conventional PCBs like aluminum printed circuits boards . Acting as a heat sink allows thermal management for heat-generating components like IC or BGAs, providing optimal performance and overheating-related issues. Furthermore, the metal core improves the durability of MCPCBs, Protecting the components from physical harm and making the board strong against moisture and dust infiltration. These benefits come naturally.

Applications of Metal Core PCBs

MCPCBs, or Metal Core Printed Circuit Boards, have distinct properties that make them useful in industries such as LED lighting systems, power supplies, motor controls, and automotive electronics. The utilization of MCPCBs as an aluminum circuit board or copper clad circuits ensures application outcomes reliable and long lasting performance by dissipating heat of high performance components

MCPCBs are widely used in industries that need dependable thermal management, like telecommunications, aerospace, automotive, and medical devices.

- Telecommunications: They are used in high-frequency communication equipment and base stations.

- Aerospace Applications: MCPCBs or aluminum pcb circuit board are widely used for avionics, satellite systems, and radar applications, where thermal stability and durability are critical factors.

- Medical Applications: MCPCBs’ thermal performance and reliability benefit medical devices such as diagnostic equipment and surgical instruments.

- Consumer Electronics: MCPCBs are commonly used in smartphones, tablets, and laptops. These devices require efficient heat dissipation to maintain optimal performance.

- Automotive industry: The automotive industry uses applications such as electric vehicle (EV) power electronics, control modules for hybrid vehicles, and advanced driver assistance systems (ADAS).

If you would like to learn more about Metal Core PCBs or receive a fast quote, please get in touch with us at [email protected] or call us now for a quick quotation!

Manufacturing and assembly of Metal Core PCBs

- PCB Material Selection: When selecting a base material, it’s important to consider the end product requirements and choose the suitable metal core material. For LED boards, usually, Aluminium material is used.

- Dielectric Layer Application: To insulate and improve thermal conductivity, apply a thermally conductive dielectric layer such as VENTEC 4A2H and ARLON 92ML.

- Circuit Layer Creation: The optically active organic dry film is completely applied to the board’s surface. After that, the board gets exposed to UV light, allowing the pattern of the outer film to be transferred onto the board’s surface. A second electroplating process removes the outer film and gets the copper etched on the outer layer.

- Drilling: The drilling process is considered a time-consuming process as to achieve proper drilling, it is required that each drill get done individually.

- Solder Mask Application: To prevent solder bridging and oxidation of the copper surface, the solder mask is applied in areas where no component placement is required.

- Silkscreen Printing: After the solder mask application, silkscreen printing gets done on the board from the printing machine to identify the component placements.

- Surface Finish: A surface finish is applied to protect the exposed copper from oxidation. We offer all types of surface finishes, which are available in-house.

- Testing and Inspection: We make sure that all the PCBs are functional; keeping that in mind, our QC team perform various tests and inspections, which include electrical testing, continuity checks and visual inspection.

- Component Assembly: For MCPCBs, Assembly involves mounting Surface Mount Technology (SMT) components.

- Final Finishing: The final step is cleaning the printed circuit board after getting the boards out from the reflow oven.

Blind Buried Circuits ensures that all challenges are overcome during production and the customer receives the high-quality boards in time.

| METAL CORE PCB MATERIAL/SUBSTRATE | ||

|---|---|---|

| DESCRIPTION | STANDARD | ADVANCED |

| Aluminum Substrate | VENTEC 4A2H - 2.2W/mK, MOT 105℃ ARLON 92ML - 2.0W/mK, MOT 90℃ |

|

| BOARD DIMENSIONS | ||

| DESCRIPTION | STANDARD | ADVANCED |

| min. Finish Board Size | 0.2"x0.2" | 0.15"*0.15" |

| LAMINATION | ||

| DESCRIPTION | STANDARD | ADVANCED |

| Layer Count | 1L to 2L | |

| SURFACE FINISH | ||

| DESCRIPTION | STANDARD | ADVANCED |

| Selective ENIG+OSP | Yes | Yes |

| ENIG(Nickel/Gold) | 80-200u"/2-9 u" | 250u"/ 10u" |

| Immersion Silver | 6-18u" | 6-18u" |

| Hard Gold for Tab | 10-80u" | 10-80u" |

| Immersion Tin | 30u"min. | 30u" min. |

| ENEPIG (Ni/Pd/Au) | 125u"/4u"/1u" min. | 150u"/8u"/2u" min. |

| Soft Gold (Nickel/ Gold) | 200u"/ 20u"min. | 200u"/ 20u" |

| SOLDER MASK / RESIST | ||

| DESCRIPTION | STANDARD | ADVANCED |

| Available Colors | White, High Reflective White | |

| S/M Thickness | 0.4mils min. | 2mils max. |

| Solder dam width | 4mils | 3mils |

| SILK SCREEN / LEGEND | ||

| DESCRIPTION | STANDARD | ADVANCED |

| Min. Space to SMD pad | 6mils | 4mils |

| Min. Stroke Width | 6mils | 5mils |

| Min. Space to Copper pad | 6mils | 4mils |

| Max Width | 28 mils | |

| Available Color | White | Black, Blue |

| ELECTRICAL TESTING | ||

| DESCRIPTION | STANDARD | ADVANCED |

| Max. Test Points | 30000 Points | 30000 Points |

| Smallest SMT Pitch | 18mils(0.45mm) | 12mils(0.3mm) |

| Smallest BGA Pitch | 12mils(0.3mm) | 6mils(0.15mm) |

| Testings Types | AOI, Flying probe Test, Bed of Nails, High Potential Test (HP-1000V) | |

Get a free quote now!

If you need metal-core PCBs, we can help! Our team specializes in manufacturing and pcb assembly service, and we will provide high-quality solutions tailored to your specific requirements.

Contact us today to learn more at [email protected].