Request our manufacturing capability

About Us

Introduction

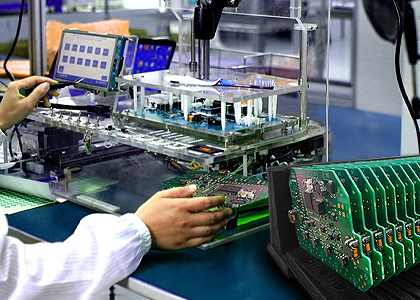

With over ten years of experience in the Electronics Manufacturing Services (EMS) industry, Blind Buried Circuits is an experienced and reliable Printed Circuit Board manufacturing and assembly service provider that caters to industries worldwide. We are dedicated to providing high-quality printed circuit board (PCB) solutions to all sizes of businesses. We have established ourselves as a trusted PCB service provider and are committed to delivering exceptional results. Our commitment to delivering the best service possible is a source of pride.

With the rapid changes in the Printed Circuit Board industry after the pandemic, we adapt to the changing needs of our customers swiftly and operate ourselves flexibly to deliver the most accurate, timely, and cost-effective design and manufacturing processes.

Our global team of experts consists of PCB designers, electronic engineers, R&D innovators, project managers, supply chain / manufacturing experts, sales/customer service professionals, and quality assurance personnel. Our production team follows all the IPC Class 2, 3, and 3A quality standards and are ISO9001 certified.

Our Team

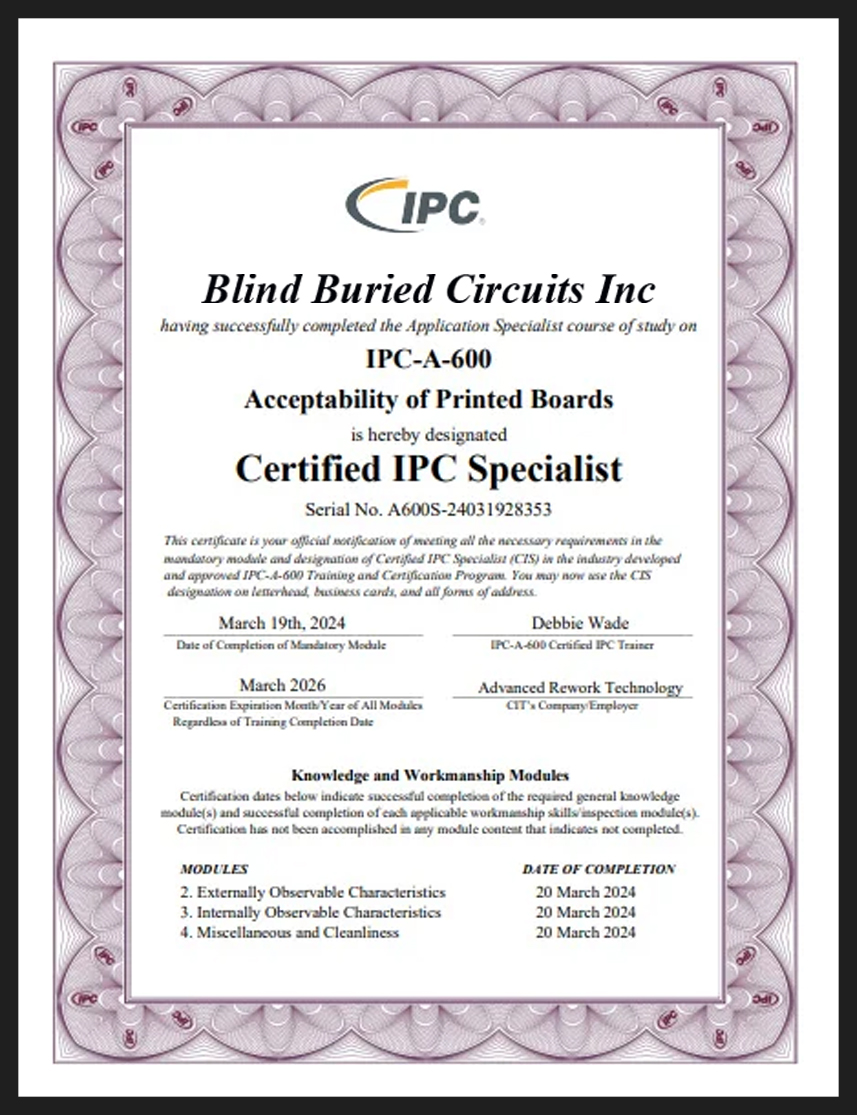

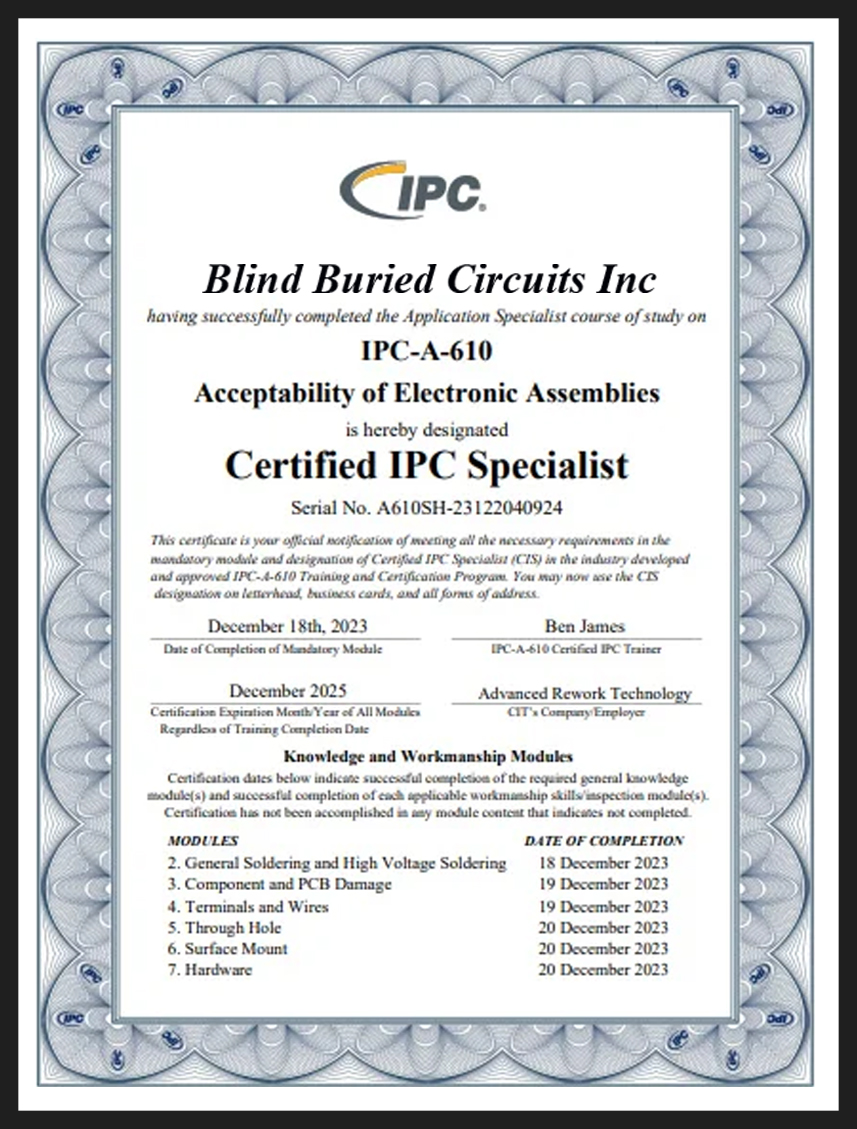

Certifications

Blind Buried Circuits Inc is certified with ISO 9001:2015 certification which underscores our focus on consistent quality management across various industries, which includes automotive, aerospace, telecommunications, industrial and consumer electronics. We continuously improve our processes to meet and exceed industry standards, ensuring High quality turnkey PCB manufacturing and customer satisfaction.

Blind Buried Circuits Inc. is ISO 14001 certified, reflecting our commitment to environmental management in the electronics manufacturing industry. This certification highlights our dedication to sustainable practices, reducing environmental impact, and to impliment international environmental standards across all our processes.

Blind Buried Circuits Inc. Assembly workmanship is also certified with IPC-A-610 standard, the globally recognized criteria for PCB assembly acceptability. This certification guarantees that our products meet strict quality requirements, ensuring optimal performance and to meet IPC Class II, III grade PCB assembly acceptability’s

Our all PCB’s and Assemblies material and finishes are as RoHS (Restrictions of hazardous substances) compliant, reflecting to our commitment to environmental responsibility.

Our all partner shops are UL certification ensures that Blind Buried Circuits Inc.'s products meet stringent safety standards as per customer requirements. This allows us to dedicatedly serve to providing safe and reliable electronic components for almost all industries.

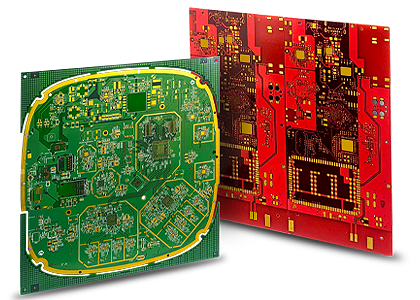

Our Capabilities

-

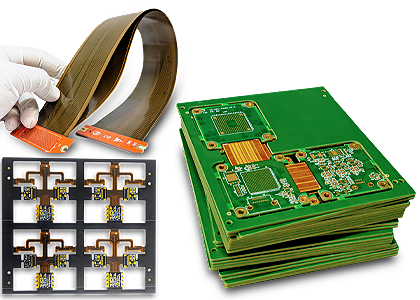

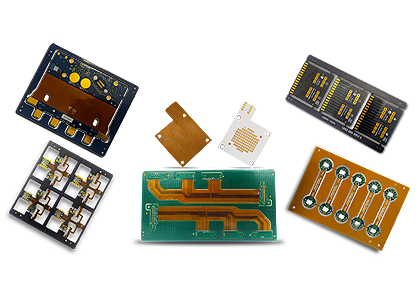

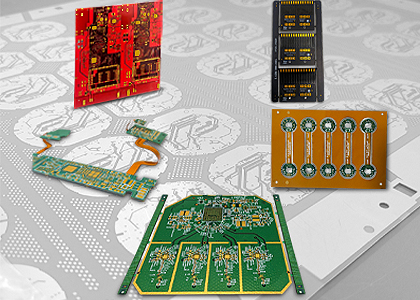

Rigid PCBS

-

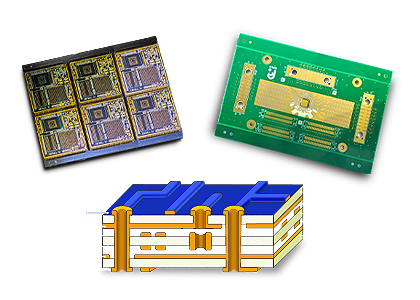

High Density Interconnect (HDI) PCBS

-

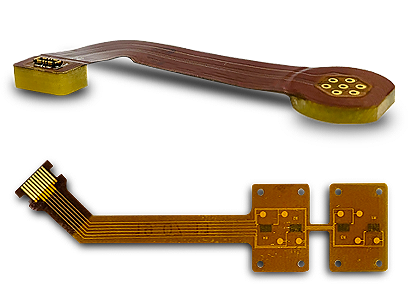

FLEX PCBS

-

Multi-Layer PCBS

-

Rigid-Flex PCBS

-

Prototype PCBS

Services We Provide

-

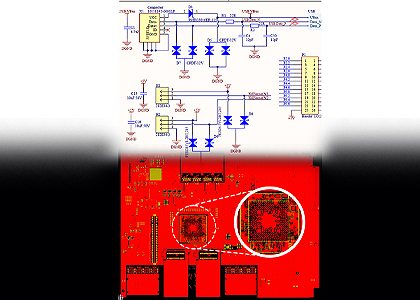

Schematics, BOM & Gerber Routing Design

-

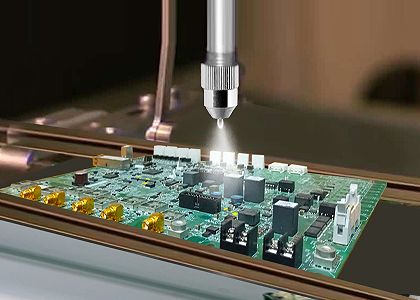

PCB Fabrication

-

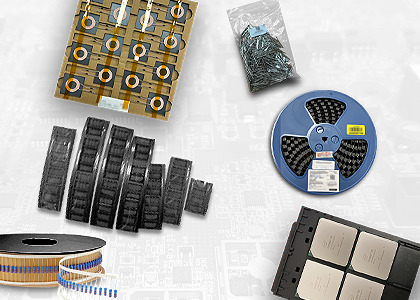

Components/Parts Procurement

-

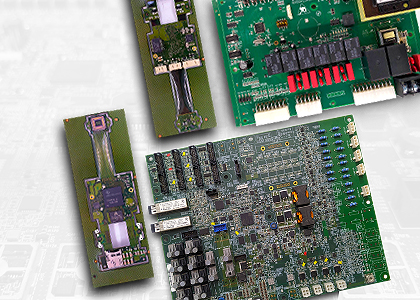

PCB Assembly labor

-

Fullturnkey PCBA's

-

Conformal Coating

-

Boot Up Testing & Inspection

Industries We Served

-

Medical Devices PCB

-

Consumer Electronics PCB

-

Automotive Industry PCB

-

Industrial Equipment PCB

-

Telecomunication