Request our manufacturing capability

Capabilities

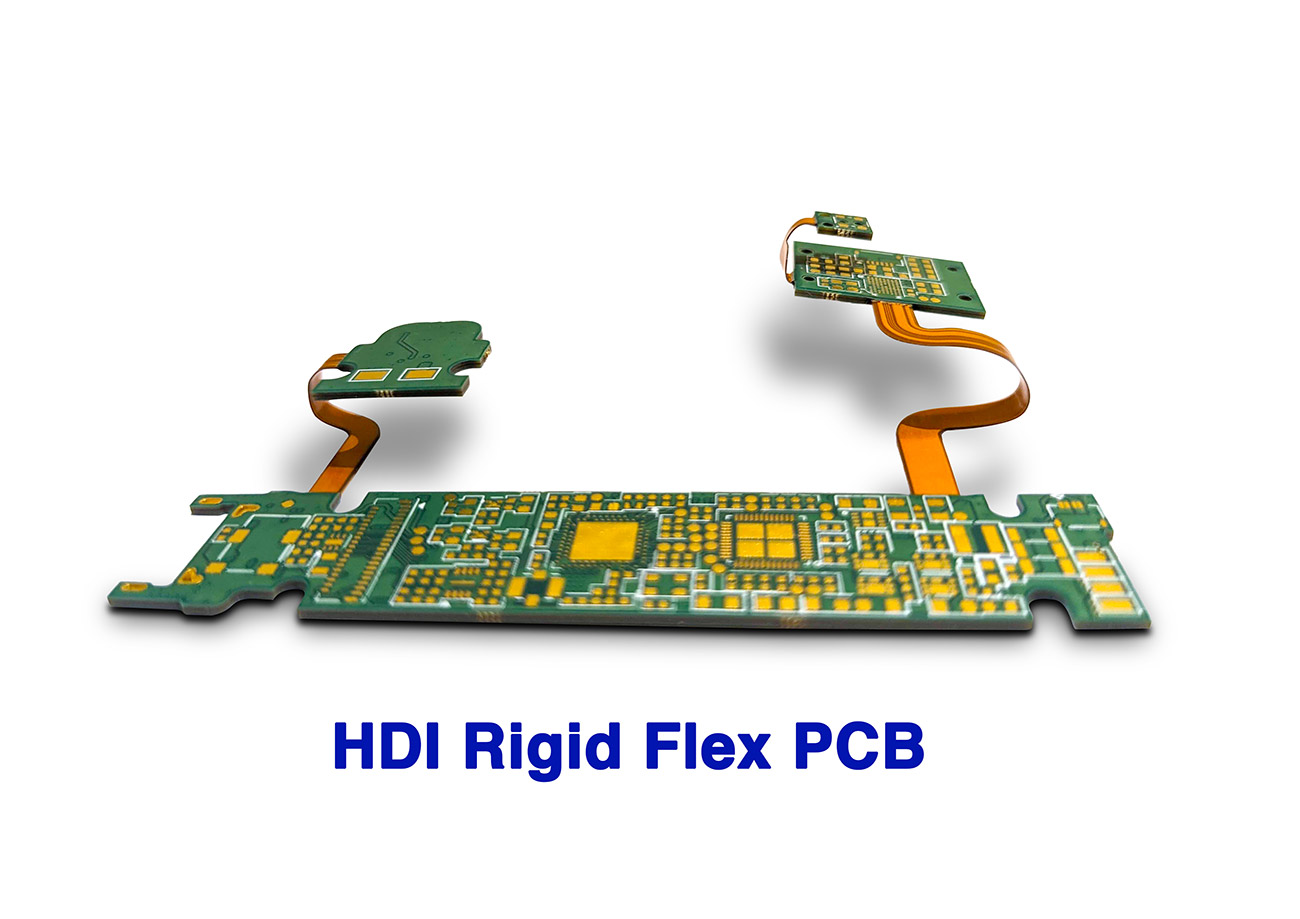

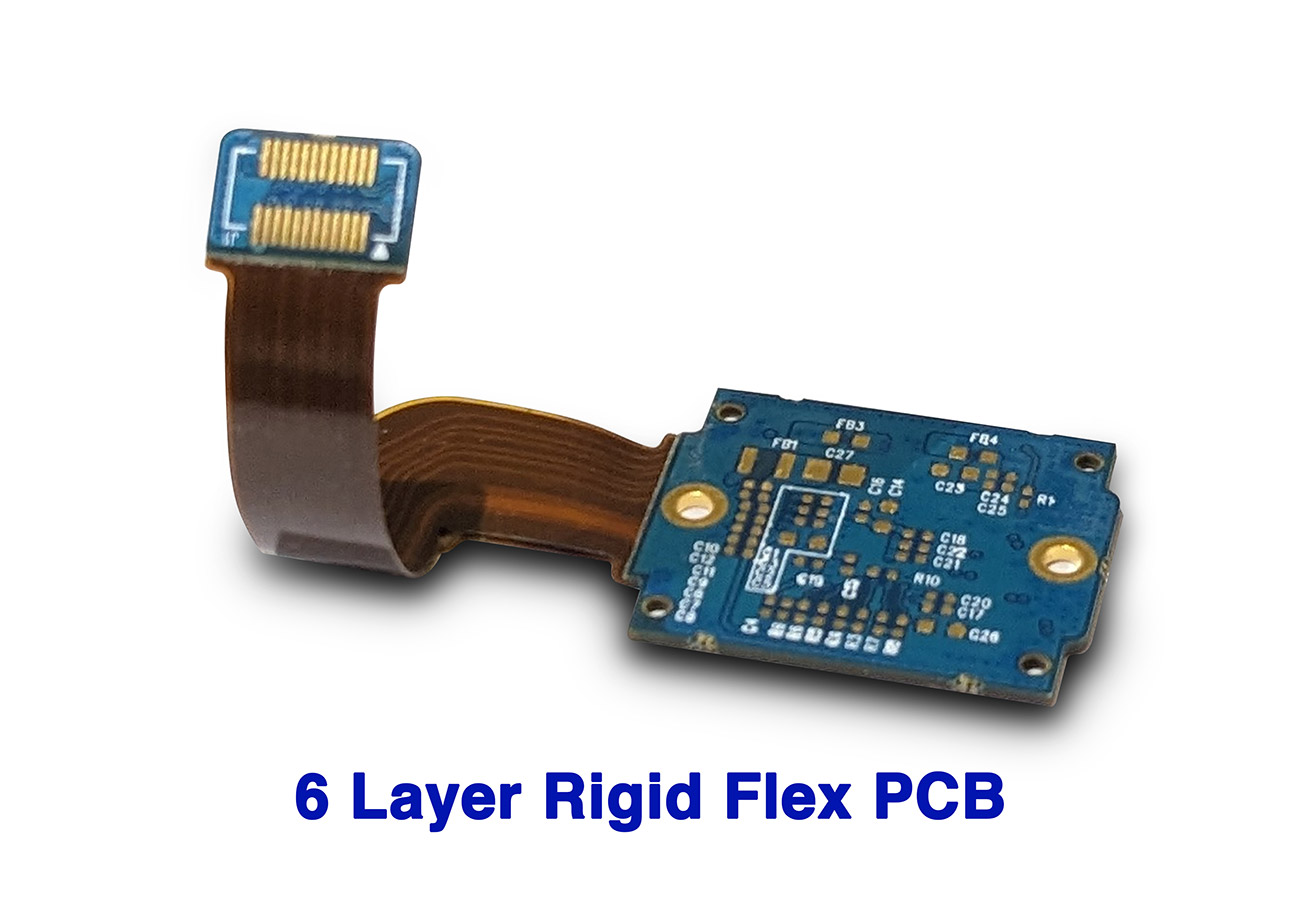

Rigid Flex PCB Manufacturer

Rigid Flex PCB Manufacturing and Assembly in the USA

Blind Buried Circuits offers high-quality rigid-flex printed circuit board manufacturing and assembly for all your product development needs. As a leading manufacturer and assembler of rigid-flex PCBs in the USA, we take pride in providing our customers with high-quality printed circuit boards that meet their custom PCB requirements.

What are Rigid-Flex PCBs?

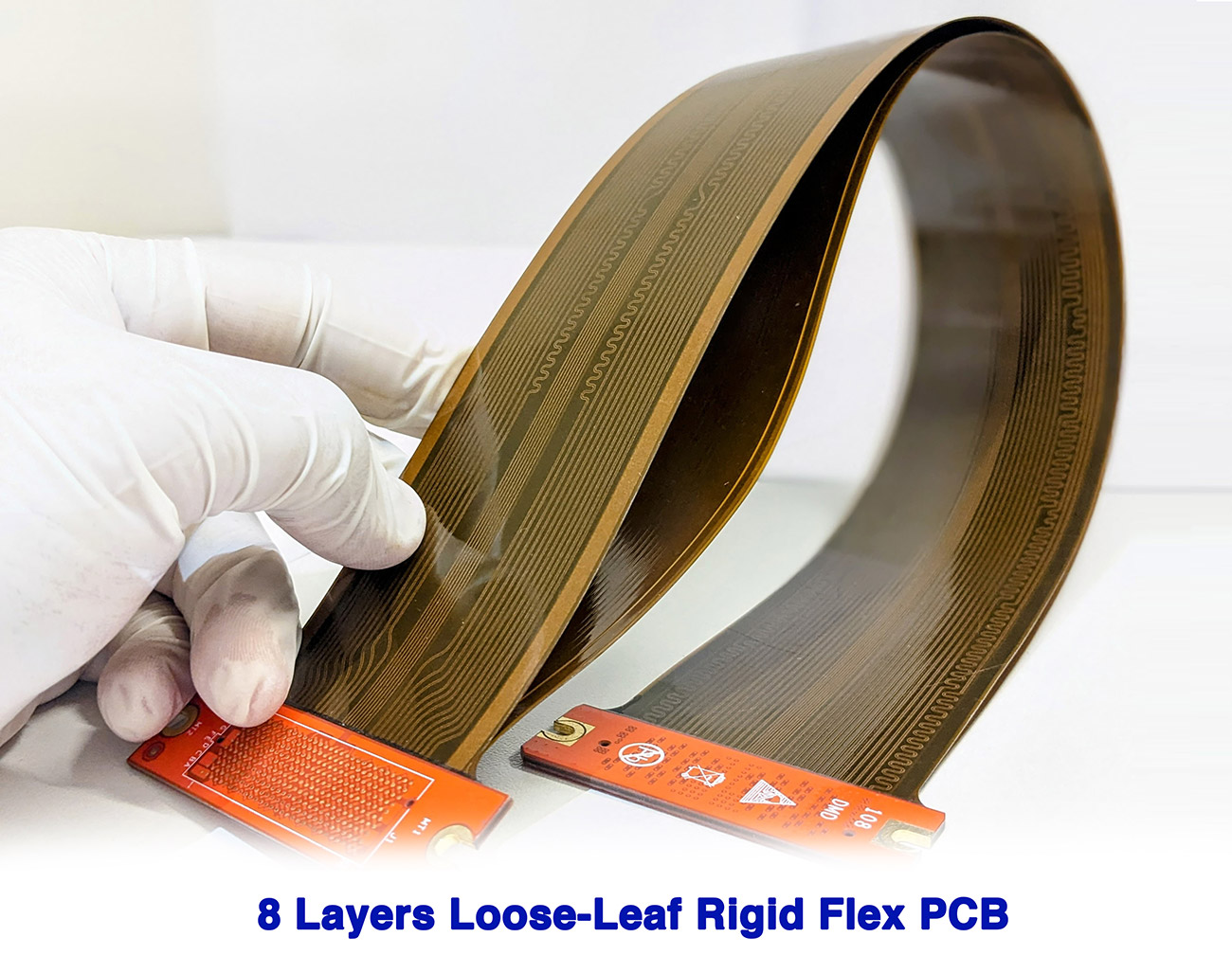

The Rigid-Flex PCBs combine rigid and flex materials, which helps customized products fit specific needs. It can be laminated in different thicknesses and accommodate many layers. The designers ensure that the traces are designed in a way that helps multiple bends and folds fit into the tight spaces. Rigid-Flex PCBs are mainly used in medical devices, aerospace systems, and military applications. They are mainly used in products with limited space and require high reliability and performance.

Blind Buried Circuits Manufacturing and Assembly Capabilities

We stock rigid and flex materials like polyimide materials in stock to keep the lead time as quick as possible. Our state-of-the-art manufacturing and assembly equipment maximize the designs’ efficiency. With skilled technicians, we deliver the highest quality standards to our customers. With the highest quality standards, our competitors unmatch our capabilities, and we thrive on serving our customers with the best customer support to optimize manufacturing lead times.

Rigid Flex PCB Design Guidelines

The below chart shows our various materials and manufacturing capabilities. Please feel feel to contact our engineering team at engineering@blindburiedcircuits.com.

| PANEL AND LAYER ATTRIBUTES | ||

|---|---|---|

| Attributes | Flex Printed Circuit Board | Rigid-Flex Printed Circuit Board |

| Layer Count | 10 | A maximum of 4 |

| Thickness of Copper | Hoz and higher. | ¼ to Hoz. |

| Line Spacing and Width | 0.003” | 0.003” |

| Panel Size Standard | 9.84” x 15.75” | 3.94” x 3.94” |

| VIA & DRILL ATTRIBUTES | ||

|---|---|---|

| Attributes | Flex Printed Circuit Board | Rigid-Flex Printed Circuit Board |

| Minimum Micro Via (Laser) Size | 3 mil | 1 mil |

| Minimum Via (Laser) Size | 1 mil | 1 mil |

| Minimum Drill (Mechanical) Hole Diameter | 0.008” | 0.006” |

| Zif Tolerance | 2 mil | 1 mil |

| Tooling Tolerance | 2 mil | 1 mil |

| SHIELDING AND STIFFENER MATERIALS | ||

|---|---|---|

| Attributes | Flex Printed Circuit Board | Rigid-Flex Printed Circuit Board |

| Shielding Material | Copper/Silver Ink/Tatsuta/Carbon | Copper/Silver Ink/Tatsuta/Carbon |

| Stiffener Material | Polyimide/FR4/Metal | Polyimide/FR4/Metal |

| PI Stiffener Registration | 10 mil | 10 mil |

| PI Stiffener Thickness Tolerance | 10% | 10% |

| FR4 Stiffener Registration | 10 mil | 10 mil |

| FR4 Stiffener Thickness Tolerance | 10% | 10% |

| SOLDER MASK AND COVERLAY ATTRIBUTES | ||

|---|---|---|

| Attributes | Flex Printed Circuit Board | Rigid-Flex Printed Circuit Board |

| Registration (Solder Mask) | 5 mil | 4 mil |

| Registration Tolerance (Solder Mask) | 5 mil | 5 mil |

| Bridging between Dam (Solder Mask) | 4 mil | 3 mil |

| Registration (Coverlay) | 7 mil | 5 mil |

| PIC Registration (Coverlay) | 7 mil | 4 mil |

| LEGENT / SILK SCREEN ATTRIBUTES | ||

|---|---|---|

| Attributes | Flex Printed Circuit Board | Rigid-Flex Printed Circuit Board |

| Registration | +/- 5 mil | +/- 5 mil |

| Minimum Space | 8 mil | 6 mil |

| Minimum Width | 8 mil | 6 mil |

| Minimum Height | 35 mil | 25 mil |

Rigid Flex PCB Design Guidelines

Before manufacturing any printed circuit board, it is recommended to check manufacturer design guidelines for efficient design and effective production yields. By keeping all the aspects of the design process, our engineering team can suggest stack-ups, insulation, and thickness to ensure that the final product meets your requirements. Please call or email our engineering team at engineering@blindburiedcircuits.com for further assistance.