Request our manufacturing capability

Speed up your PCB manufacturing and PCB Assembly

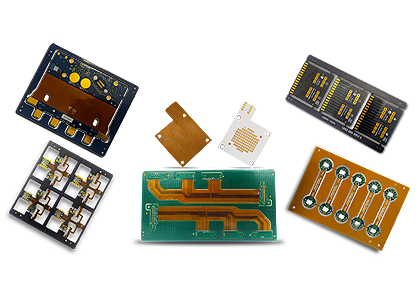

Blind Buried Circuits has been an industry leader in quick turn and custom PCB manufacturing and assembly, serving the industry with our PCB turnkey services for many years. Our specialty includes advanced Rigid, Flex, and Semi flex circuits manufacturing and assembly with our quick turn lead times capabilities, and offer both prototype and large volume quantities. We are an ISO 9001, ISO 13485, ISO 14001, IPC Certified (IPC A 600 and IPC A 610) certified Turnkey Electronic Manufacturing Services (EMS) provider, we adhere to all QMS and IPC Standards including Class 2, 3, and 3A, ensuring excellence in every project. Our expertise spans Research and development, product manufacturers from diverse industries including telecom, loT, avionics, automotive, medical devices, industrial sectors, and consumer electronics. Experience hassle-free product development by choosing our turnkey manufacturing and PCB manufacturing services by considering Blind Buried Circuits as your trusted partner for your present or upcoming projects.

About Us

Blind Buried Circuits Inc. makes it fast and easy to get your custom PCB board design manufactured and assembled under white hand service, hassle-free at a competitive price. With our ultra-fast manufacturing processes we are serving across borders which allows us to take the opportunity to work domestically all over the United States of America and Canada, We provide modernized Turnkey Manufacturing solutions to R&D and electronic product manufacturers for their innovative electronic devices at the most competitive and cost-effective pricing for standard and complex custom PCB’s designs. With the latest technology-equipped facilities for PCB Fabrication & PCB Assembly, our commitment to quality assurance always remains a priority. We guarantee quality control and reliable circuits for each project

Our Capability Includes:

- Quick lead time with custom PCB production, where we handle your project from initial DFM, DFA, Fabrication, Component procurement, Assembly process, and Box build (optional).

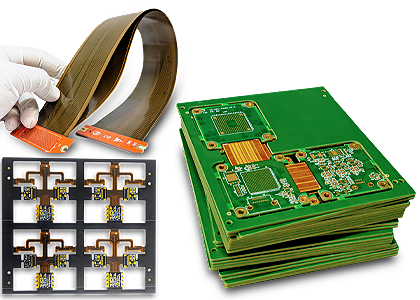

- We manufacture and assemble all PCB board types including Rigid, Flex & Rigid-Flex with standard or special design requirements.

- Exotic Rigid PCB and Flex PCB Substrate with multiple alternatives to achieve custom stack-up requirements for design contains High-Speed Digital and High-Frequency RF and high-temperature requirements.

- Variety in types of surface finishes which include Leaded HASL, Leadfree HASL, Immersion Silver, Immersion Tin, ENIG 2-5µ”, Soft Gold 8-1 0µ”, ENEPIG, Hard Gold 30-70µ” including selective surface Area plating.

- Minimum 2/2mils trace width and spacing with controlled Impedance signals.

- High Multilayer Count up to 50 layers with HDI (high density interconnect) requirements.

- Procurement of Restricted, Obsolete, and Hard-to-source components with trusted, authentic, and reliable partners based in domestic and offshore.

We take this opportunity to partner with you: let’s start this journey with Blind Buried Circuits Inc and experience success just after an order away.

Our Capabilities

-

Rigid PCBS

-

High Density Interconnect (HDI) PCBS

-

FLEX PCBS

-

Multi-Layer PCBS

-

Rigid-Flex PCBS

-

Prototype PCBS

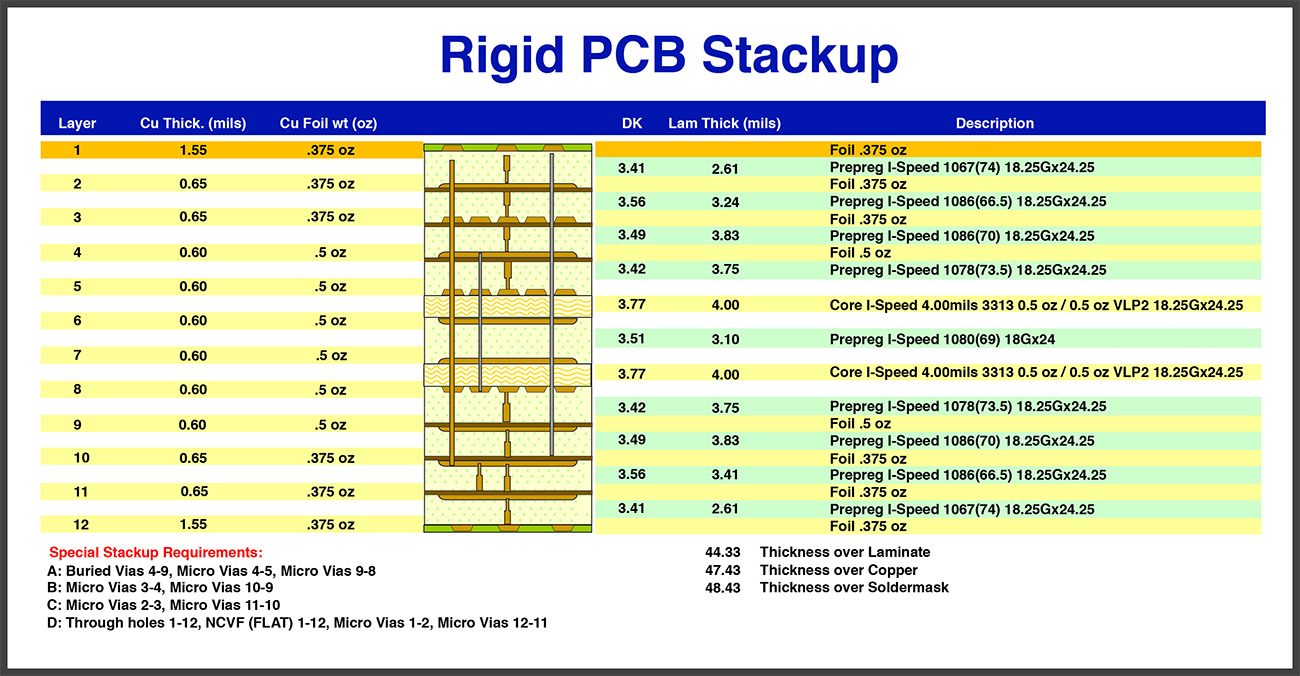

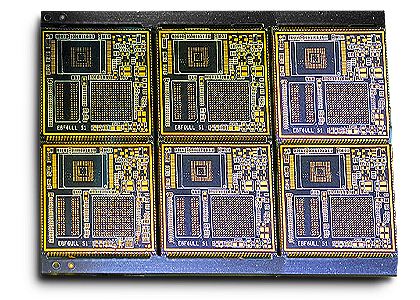

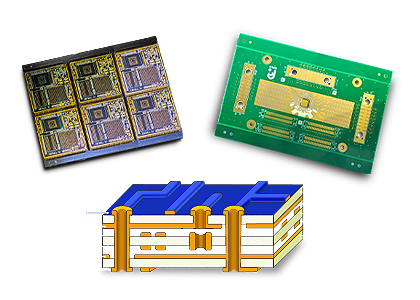

Our Rigid PCBs manufacturing are all RoHS compliant. The capabilities include the use of multiple standard ISOLA FR4 (prepreg and core materials), alongside specialized options like 370HR, FR408HR, Rogers, Aluminum metal clad (mcpcb), copper clad laminates, Nelco, Megtron, and Panasonic. We support complex designs with impedance control and multilayer lamination up to 50 layers.

Our HDI circuit capabilities allow our customers to design complex and fast signal transmission lines. Blind buried circuits HDI manufacturing capability includes Mechanical and laser Blind Via/ Micro Via, Buried Via, Stacked, and staggered spans for rigid, flex, and rigidflex circuits.

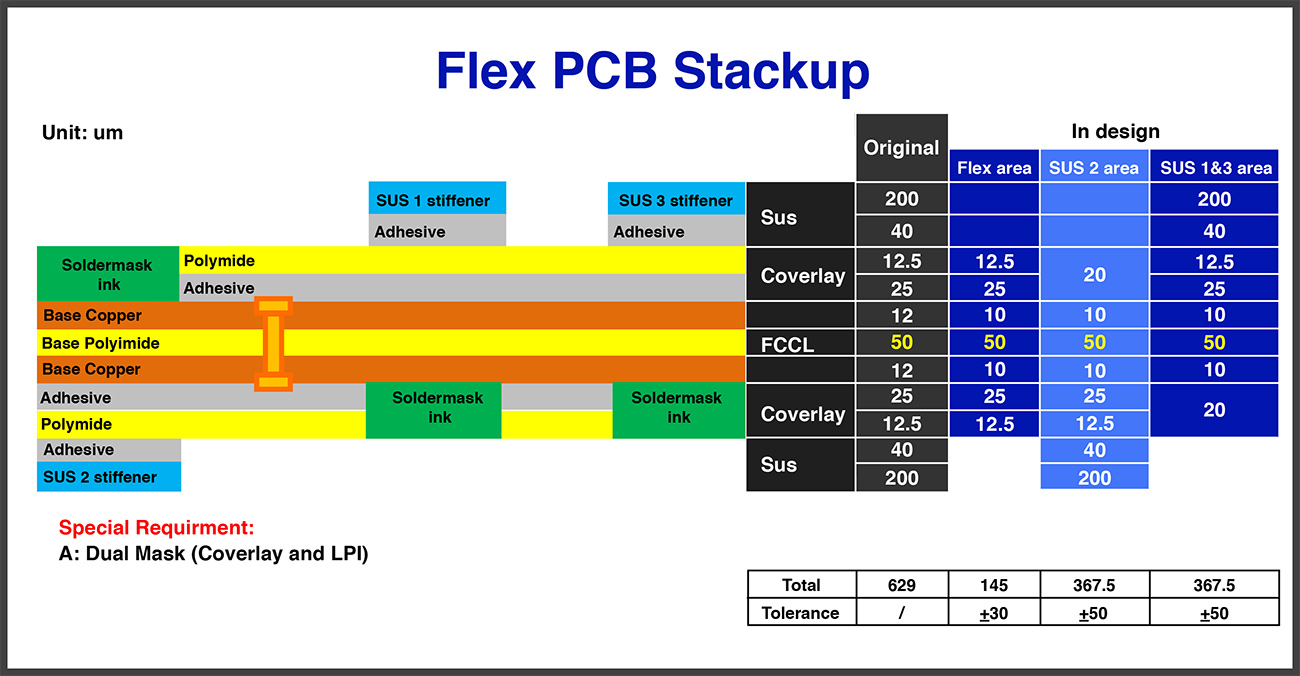

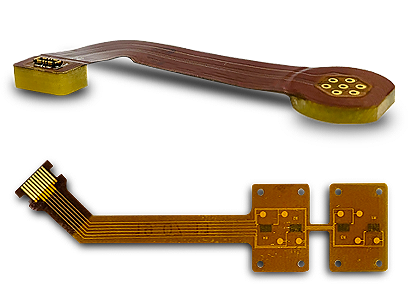

Our Flexible PCB manufacturing capabilities include multilayer flex laminations up to 6 layers, we ensure to meet end-user stack-up requirements especially the controlled circuit thickness to ensure their circuit bandwidth requirements. We use standard materials such as Polyimide (PI) and special materials like PTFE flex cores. Our standard flex thickness is 0.008” (+/- 4mils) however we can also accommodate critical needs of special requirements as per design.

Multilayer technology allows RF layout designers to achieve optimal performance in complex environments. Our capabilities include the hybrid multilayer PCBs for Rigid, flex, and Rigid-Flex up to 50 layers of laminations. We support complex designs with impedance control alongside multiple surface finishes and other complex capabilities.

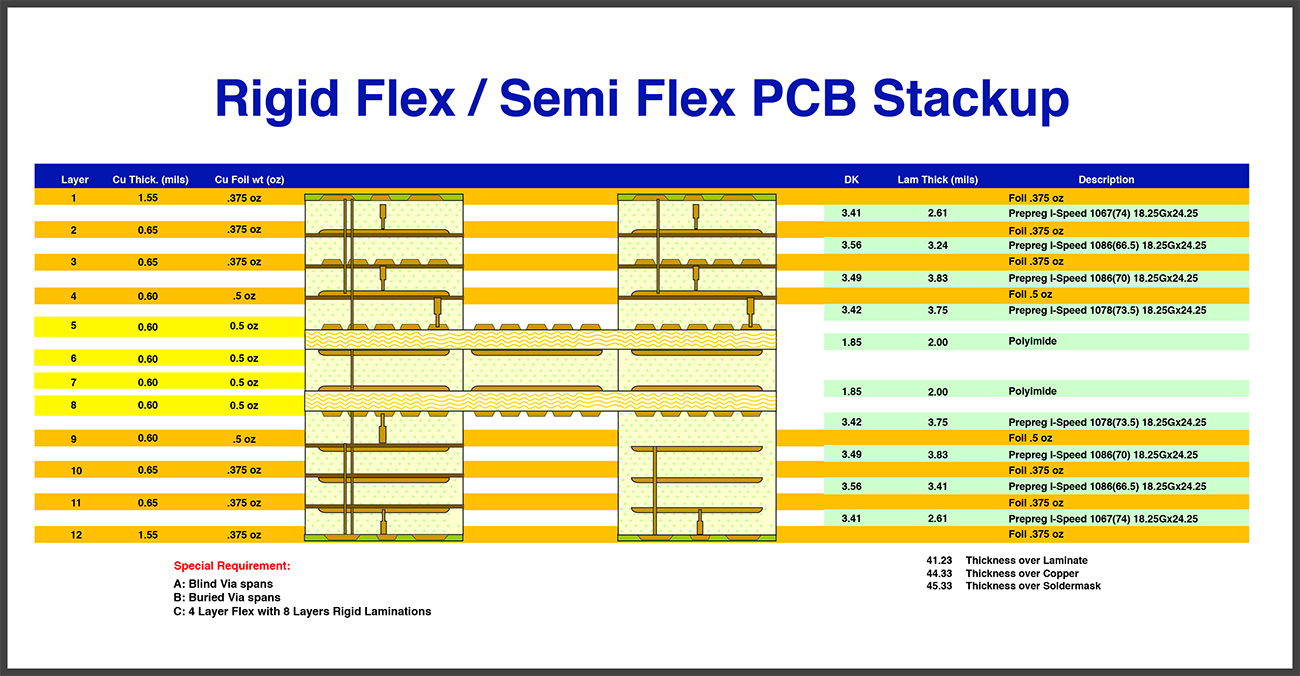

Our advanced rigid-flex capabilities include hybrid Layer laminations, with controlled Impedance and various types of special materials for rigid and flex substrates. We ensure to meet the stack up requirements of end-product designers.

In the era of Research & Development, Our Turnkey Manufacturing Services are becoming a core value for design and layout engineers to streamline their projects from concept to reality and maintain “time to market” commitments. We provide turnkey manufacturing services for prototypes and mass production or volume quantities. We have a core supply chain with trusted partners.