Request our manufacturing capability

Speed up your PCB manufacturing and PCB Assembly

Blind Buried Circuits has been an industry leader in PCB manufacturing and assembly services for over 10 years. We specialize in quick-turn PCBs, catering to both small and large production quantities with high-quality and reliable printed circuit boards. As an ISO 9001 certified Electronic Manufacturing Services (EMS) provider, we adhere to IPC Standards Class 2, 3, and 3A, ensuring excellence in every project. Our expertise spans diverse industries, including telecommunications, loT, avionics, automotive, medical devices, industrial sectors, R&D, and consumer electronics. Whether you need prototypes or full-scale production, we deliver maximum value and performance. Experience hassle-free manufacturing with us and choose Blind Buried Circuits as your trusted partner for your next project. Contact us now to get started.

About Us

Ready to bring your tech projects to life? Blind Buried Circuits makes it easy to get PCB manufacturing and assembly done in no time at a competitive price. With our ultra-fast manufacturing services spread across states, we make PCB layout design & circuit board production effortless – you’ll be kicking yourself for not starting sooner. We provide modernized manufacturing solutions at the most competitive prices for single-sided PCBs, copper clad laminates,

Our Capability Includes:

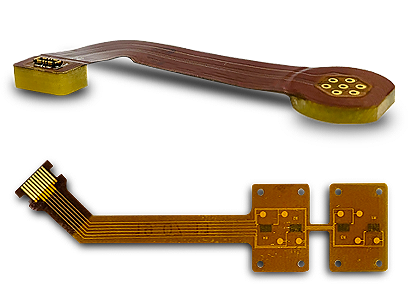

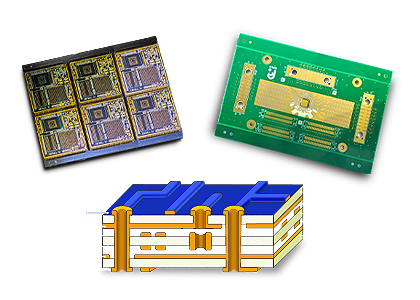

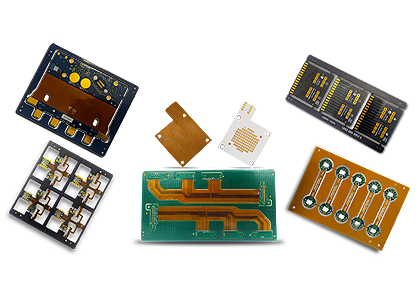

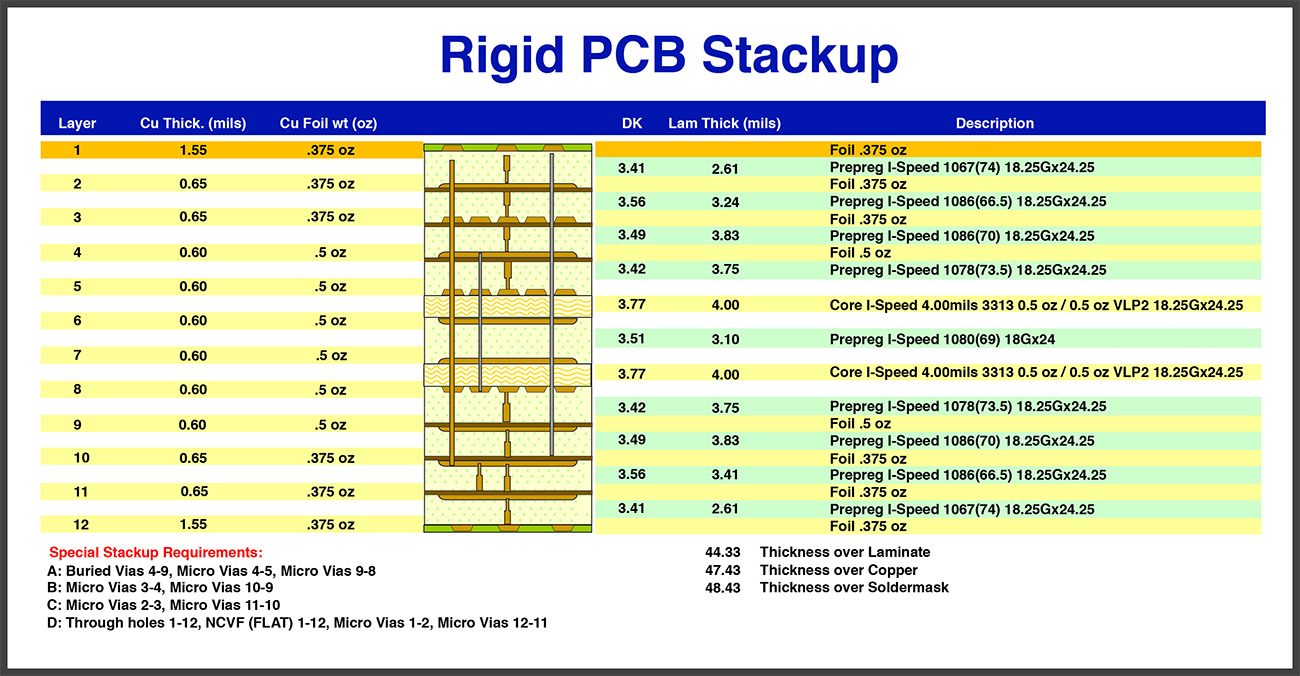

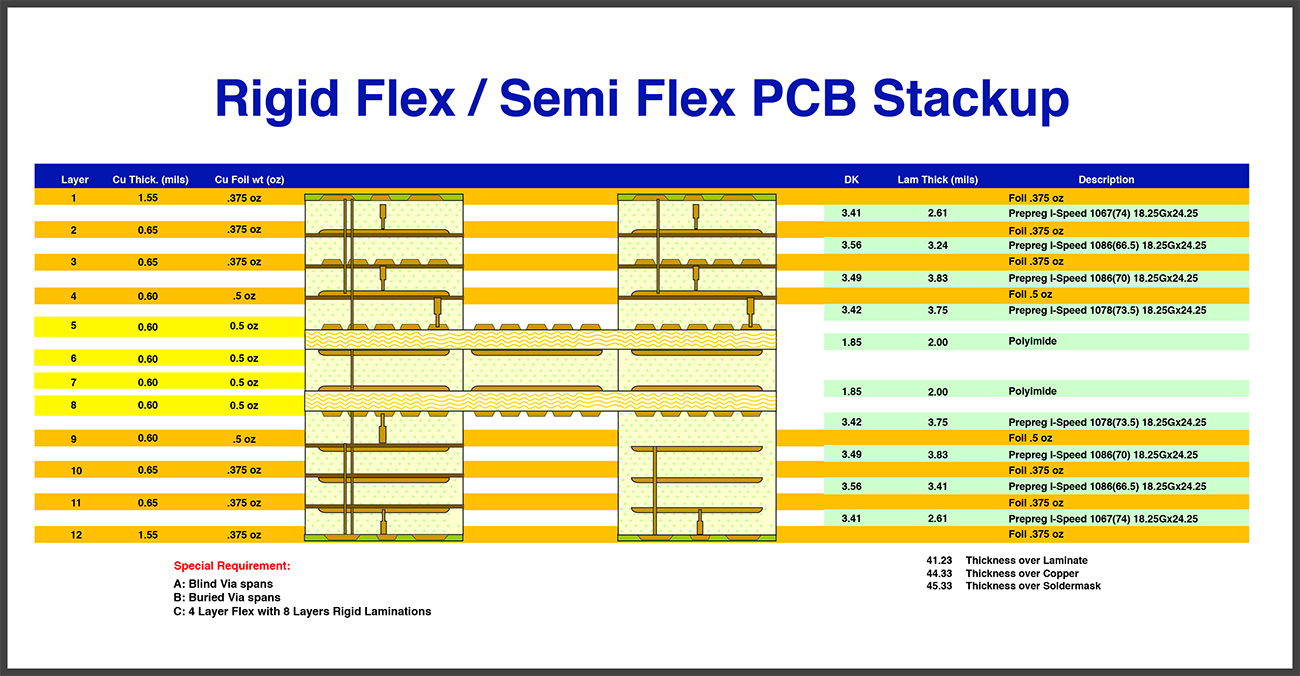

- Manufacturing of complex HDI stackups for Rigid, Flex & Semi flexible circuits.

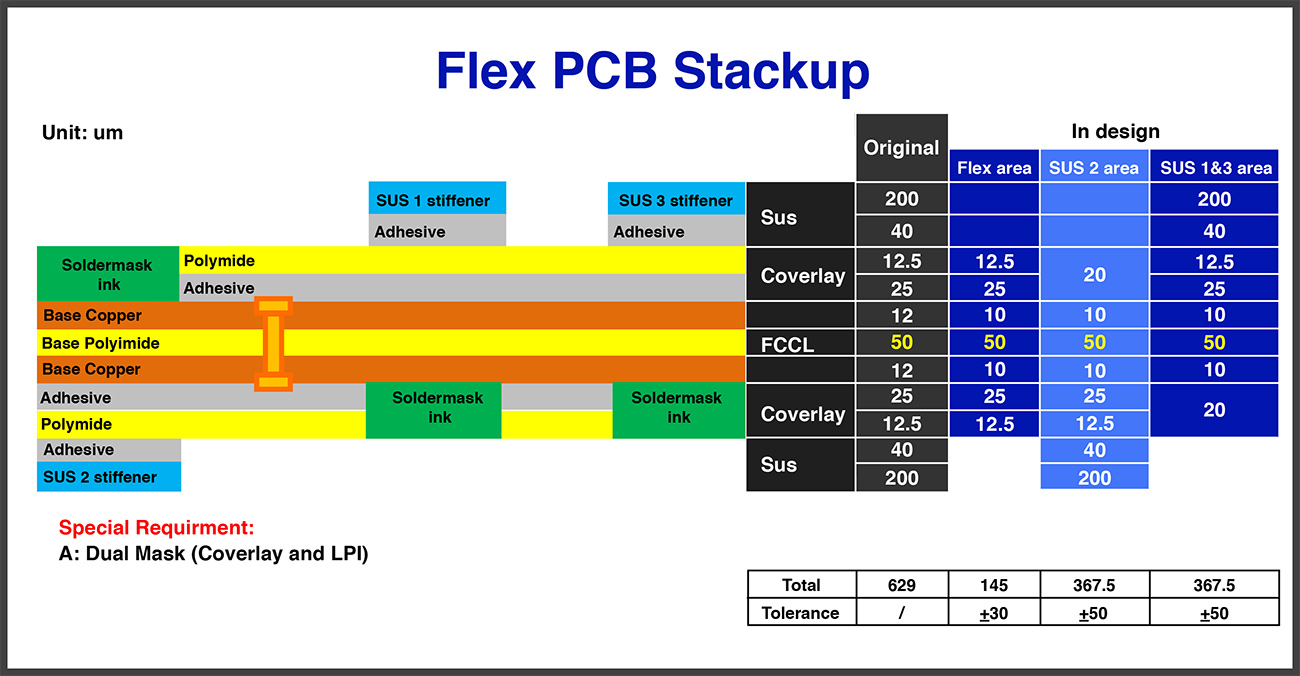

- Multiple solder mask and coverlay for thermal and cosmetical rigid and flex circuits.

- Get the good performance and solder reliability with surface finish with Leaded HASL, Leadfree HASL, Immersion Silver, Immersion Tin, ENIG 2-5µ”, Soft Gold 8-1 0µ”, ENE PIG, Hard Gold 30-70µ”, Gold fingers and edge-plated PCBs for multiple benefits as connectors.

- Achieve fine line & spacing as low as 2/2mils for tiny circuits and precise requirements.

- In stock special RF compliant PCB Materials including Isola 370HR, FR408 HR, Rogers, Nelco, Megtron, Tachyon, Pl (Arion) and PTFE based on the requirements

Take the leap into innovation today: Start your PCB Supplier journey with Blind Buried Circuits; success is only an order away.

Our Capabilities

-

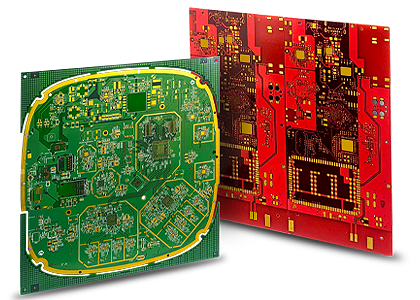

Rigid PCBS

-

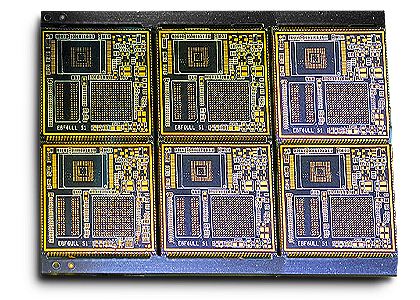

High Density Interconnect (HDI) PCBS

-

FLEX PCBS

-

Multi-Layer PCBS

-

Rigid-Flex PCBS

-

Prototype PCBS