Request our manufacturing capability

Capabilities

PCB Prototyping Services in the United States and Canada

PCB Prototyping Offer

At Blind Buried Circuits, our focus is to provide printed circuit boards rapidly to our customers with accuracy and functionality in their initial PCB designs. We have introduced several “Prototyping Offers” for our customers, catering to fabrication and assembly. We aim to provide quick and budget-friendly prototype PCBs in the United States and Canada.

Our PCB prototyping capabilities are as follows:

- Quick PCB Prototype Bare Boards or PCB Assembly in 24 to 48 hours (Upto 6 layer count)

- Standard PCB Prototype Bare Boards or PCB Assembly in 10 days (5 days fabrication and 5 days assembly labor)

- Special Prototype Requirement or High Layer Count Prototype PCBs with 500+ components, BGA assembly requirements.

To get a quote for introductory PCB prototyping, please fill out our quote form to get a quick quotation or call us now to talk with PCB experts for your Prototype PCBs.

Get Your PCB Prototyping At the Quickest Lead Time

IPC Quality Standards for Fast Turnaround Lead Times

IPC, or the Institute of Printed Circuits, has set standards for manufacturing Printed Circuit Boards. At Blind Buried Circuits, we manufacture the PCBs as per the IPC Class 2 and IPC Class 3 standards.

Blind Buried Circuits provides PCB prototypes in quick and standard lead time to various industries, including:

- Aerospace Corporations

- Motor Vehicles

- Super Computers and Computer Clusters

- Industrial Applications

- Healthcare industry

Depending on the design requirements, we can offer our customers all the advanced IPC standards. To learn more about our capabilities and lead times, please email us at sales@blindburiedcircuits.com.

PCB Prototype Testing and Inspection:

At Blind Buried Circuits, all the testing and inspection occur per IPC’s direction. All our boards are completely inspected and tested before production. Our preproduction check includes the following:

- Design Rule Check (DRC).

- Preproduction Design For Manufacturing (DFM) Analysis.

- Netlist testing.

- Standard Electrical Flying Probe Testing (Open and Short).

- Automated Optical Inspection (AOI) on every step of PCB production.

- Design For Assembly (DFA) before PCB assembly and Component Procurement.

- BOM Analysis.

At the production stage, we ensure that all the PCBs are visually inspected before the PCB shipment. These testing procedures benefit our customers by avoiding major design flaws, schematic diagram errors, open and short circuits, and hard-to-source component issues.

We also offer advanced testing, which requires extra cost and lead time. To learn more about our PCB testing capabilities, please fill out our quote form and mention your special requirements in the comment box to get a quick quotation.

Comprehensive Functional Testing for Prototyping PCBs

At Blind Buried Circuits, we ensure every prototype PCB undergoes a thorough functional test before it moves into mass production. This ensures the electronic components are operating as expected, and that the board can handle real-world conditions. Our comprehensive testing helps customers avoid costly errors during the production process, providing reliable and high-performing PCBs.

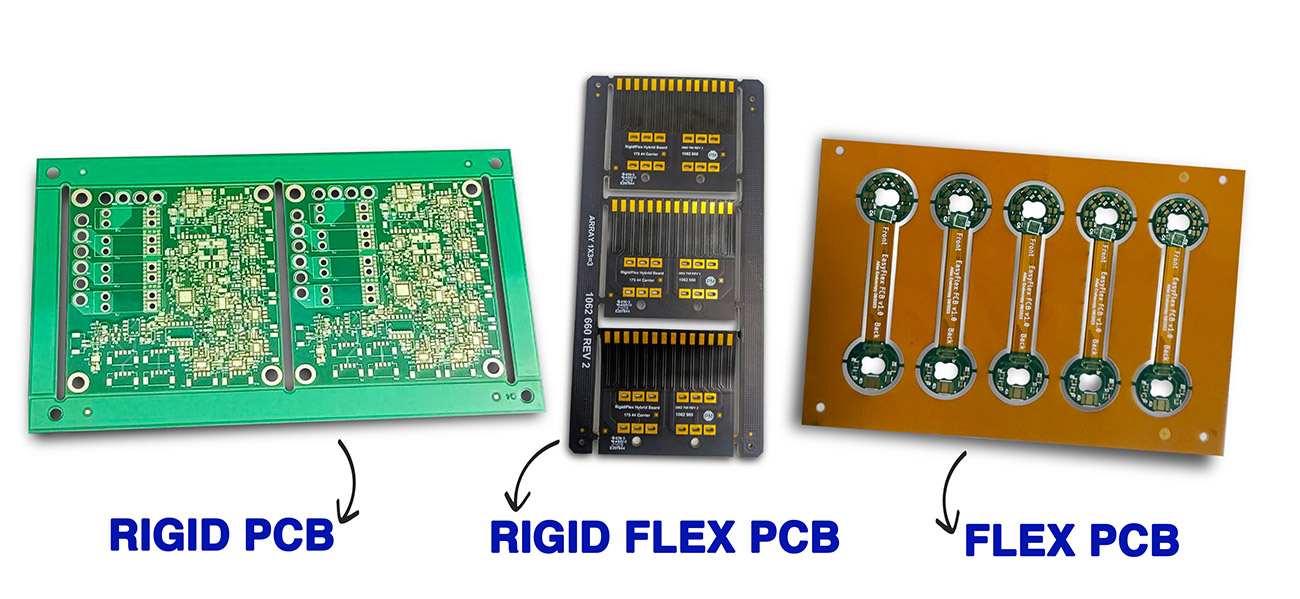

Blind Buried Circuits is a renowned supplier of critical circuit boards to customers across the United States and Canada. We have limitless technologies with the help of multiple partners all over the globe; we ensure that all the printed circuit board requirements are fulfilled with the highest quality standards. We offer various PCB prototyping technologies, including:

- Rigid PCBs

- Flex PCBs

- Rigid-Flex PCBs

- HDI PCBs

- Metal Core PCBs

- LED PCBs

- High-Frequency PCBs

- High TG PCBs

- Thick-Copper PCBs.

Efficient PCB Fabrication and Drilling Holes for Prototyping

Our PCB fabrication process includes precise drilling of holes for vias and component placements, ensuring strong connectivity between copper layers. We utilize advanced PCB prototyping equipment to deliver accurate results, minimizing errors in early-stage prototyping PCB development. This ensures your printed circuit boards (PCBs) are ready for high-volume production.

Turnkey Assembly for Quick Turn PCB Prototyping

For a seamless transition from prototyping to production, Blind Buried Circuits offers turnkey assembly services. This includes handling everything from PCB board prototyping to component sourcing and final assembly. Our turnkey PCB assembly approach helps reduce the production lead time, allowing you to get your product to market faster.

Why Choose Blind Buried Circuits For Your PCB Protos:

At Blind Buried Circuits, we focus on providing customers with the best customer service and around-the-clock engineering support in the United States and Canada. Someone is always there to help you with our engineering support team to ensure complete customer satisfaction and get the additional prototypes to the production stage on time.

Once the prototypes are ready for production, we provide hassle-free Full Turnkey PCB production services, which provide one window PCB production and no additional tooling costs.

Ensuring Product Quality through PCB Prototyping Services

Blind Buried Circuits is dedicated to maintaining high product quality in every stage of rapid PCB prototyping. Our rigorous quality control processes, including electrical tests and automated optical inspection, ensure your prototyping circuit boards meet the highest standards for performance and durability. We are committed to delivering prototypes that perform reliably in even the most demanding applications.

Final Quality Assurance (QA) Inspection of Assembled Boards

At Blind Buried Circuits, we do a QA inspection on each step for all prototype PCB fabrication, and after the reflow process, our dedicated QA inspection team checks all the solder joints by automatic optical inspection (AOI) and visual inspection. It helps prevent soldering issues and identify them before shipping the boards to our customers.