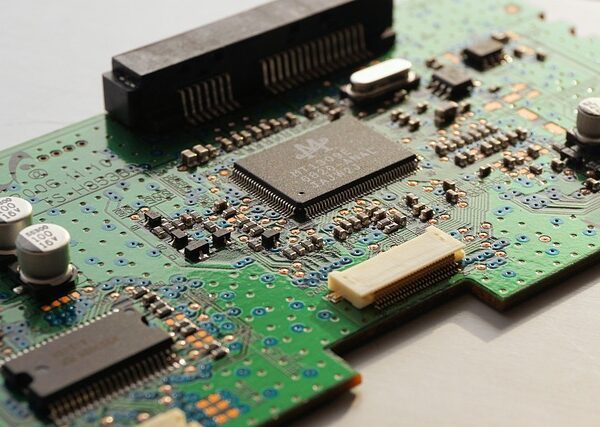

FR4 PCB Manufacturing: Types, Benefits & Applications

FR-4 PCBs are made of woven fiberglass, epoxy and resin material where F stands for Flame, R stands for Retardant and 4 stands for reinforced woven glass epoxy resin. At Blind Buried Circuits we offer standard, medium and High TG FR-4 PCBs as per our customer’s design requirements. FR-4 PCBs are used in various industries and are cost effective, flame resistant and easily available for high frequency applications.

FR-4 Materials

FR-4 itself is a material grading. The grading indicates the flame resistant property of the material and its electrical insulator performance. FR4 substrate materials are known for its mechanical strength, FR4 dielectric constant and fr4 dissipation factor making it ideal for high frequency applications.

The material composition includes woven fiberglass and epoxy resin providing moisture absorption resistance and heat dissipation. FR-4 materials are used in single sided, double sided, multi layer printed circuit boards. FR-4 substrate material can be selected based on its electrical properties, dielectric constant of PCB materials and number of layers required for specific electronic devices.

FR4 PCB materials are used in single sided, double sided, multi layer printed circuit boards. The categories of FR-4 materials can be selected based on the function, impedance requirement and number of layers. The following are the categories of FR-4 material:

- Class A1 – FR4 Copper Clad Laminate: Class A1 is benchmarked as the highest grade and best in performance. Military, communication, digital circuits, industrial applications, automobile and electronic products like computers mainly use this class.

- Class A2 – FR4 Copper Clad Laminate: Class A2 is benchmarked as the standard grade and best in price. This class is mainly used by companies that create personal computers, advanced domestic applications, meters and instruments and standard electronics products.

- Class A3 – FR4 Copper Clad Laminate: Class A3 is benchmarked as below standard grade and is down in price. This class is mainly used by companies that create domestic appliances, computer output devices and ordinary products like toys, calculators and gaming consoles.

- Class A4 – FR4 Copper Clad Laminate: Class A4 is benchmarked as low end material with most competitive pricing. This class is mainly used by companies that create basic domestic household appliances, personal computers and basic electronics products.

- Class B – FR4 Copper Clad Laminate: Class B is benchmarked as the poorest quality and stability. Not all companies use this class, which is only suitable for 100 mm x 200 mm PCBs. That’s why many companies pay attention before selecting Class B – FR-4 copper-clad laminate.

FR-4 Printed Circuit Boards

FR4 printed circuits boards have the following features:

- Physical Appearance: Copper clads are on top and bottom sides and an insulation substrate in the middle.

- Material thickness: FR-4 material is available in various thicknesses and used as per the design requirements. Thickness from 1.3 thou to 3 inches are usually used in most designs. It is also used in flexible printed circuit boards due to the thinner material thickness.

- Material Properties: FR-4 is a high quality insulating material and provides excellent mechanical strength, thermal management and electrical insulator capabilities making it ideal for electronic components in consumer electronics.

- Functionality: To make a working circuit the FR-4 PCB is a basic skeleton for connecting all the components per the circuit design.

- Impedance matching: Most FR-4 PCBs are used in high frequency application circuit designs. It can be matched by considering the DK (FR-4 dielectric constant) and DF (dissipation factor) for precise PCB design requirements.

- Material Composition: At Blind Buried Circuits, we offer FR-4 PCB manufacturing up to 24 layers ensuring optimal electrical performance and heat dissipation for critical applications.

- Operating Temperature: FR-4 printed circuits board are good conductors of heat. The value of the thermal coefficient of the dielectric constant determines the temperature management of FR-4 material.

Blind Buried Circuits FR-4 PCB Manufacturing Capabilities

Blind Buried Circuits is a US and Canada-based PCB manufacturer of FR-4 PCBs. Our material properties allow us to provide reliable electrical performance for high quality printed circuit board PCB manufacturing for electronic components and consumer electronics. Here are our manufacturing capabilities:

- Number of Layers: 2 – 50 Layers

- Board Size (Max): 24 inches X 22.51 inches

- Substrate Material: FR- 4, FR- 4 Hi TG, FR- 406, 370 HR

- Surface Finish: Leaded HASL, Lead-Free HASL, Leaded HASL+Gold finger, ENIG, OSP, Immersion silver, Immersion Tin

- Legend (Silk Screen) Color: White, Black, Yellow

- Board Thickness: 0.078″ (Min) to 0.3149″ (Max)

- Min Line and Spacing: 3 mil / 3 mil

- Smallest Drill Size: 8 mil

- Stiffener Material: Aluminum, Steel, and FR4

- Copper Thickness: H oz – 6 oz

Benefits and Applications of FR-4 Printed Circuit Board

At Blind Buried Circuits, our FR-4 PCBs are used in various industries and provide benefits to our customers. Here are some benefits and applications of FR-4 PCBs.

- Mechanical Strength: FR-4 has excellent mechanical strength.

- Electrical Insulator: The epoxy resin layer makes it an electrical insulator.

- Heat Dissipation: FR-4 is a good conductor of heat.

- Moisture Absorption: Low moisture absorption.

Why Blind Buried Circuits for your FR-4 PCB Manufacturing in US and Canada

Blind Buried Circuits is a high quality FR-4 PCB manufacturer for electronic devices and consumer electronics. We ensure your PCB has superior mechanical strength, electrical insulator properties and good heat dissipation for higher frequency applications., then Blind Buried Circuits is your best choice; we are a team of experienced experts who understand PCB manufacturing, Component Procurement and Assembly labor. We have been serving our customers for the last 10 years without any delay in lead time. All our customers are from US and Canada. To get a quote today, please submit our quote form or email us at [email protected].