Request our manufacturing capability

Capabilities

PCB Assembly

PCB Prototype Assembly

Blind Buried Circuits Value-Added Benefits

- No minimum order quantity required: We believe in catering to all our customer’s needs, whether they require a small, medium, or large production run.

- No set-up fees: Our pricing is transparent, and we do not add additional PCB assembly costs as set-up fees.

- Engineering prototypes: We offer engineering prototypes, allowing our customers to test and make necessary product changes before moving to production.

- No stencil charges: Our goal is to make board assembly services affordable for all our customers. That’s why we do not charge additional stencil fees.

- Low-cost first article (FA) builds: We offer first article (FA) builds at a low PCB assembly cost to help our customers quickly bring their products to market.

- State-of-the-art PCB assembly equipment: We use the latest and most advanced pick-and-place machines and reflow ovens for PCB assembly, ensuring that all the assemblies are done efficiently.

- Stainless steel laser-cut stencils: We provide stainless steel stencils on next-day delivery.

- CAM file review: Before starting the PCB manufacturing and PCB assembly process, we thoroughly review all design files to ensure accuracy and efficiency.

- Seamless PCB flow: Our streamlined manufacturing and assembly processes prevent delays.

- Hard-to-source parts: Our procurement engineers are always ready to help you get all the hard-to-source parts from the grey market. Feel free to share the part number at [email protected] for quick assistance.

PCB Assembly Capabilities

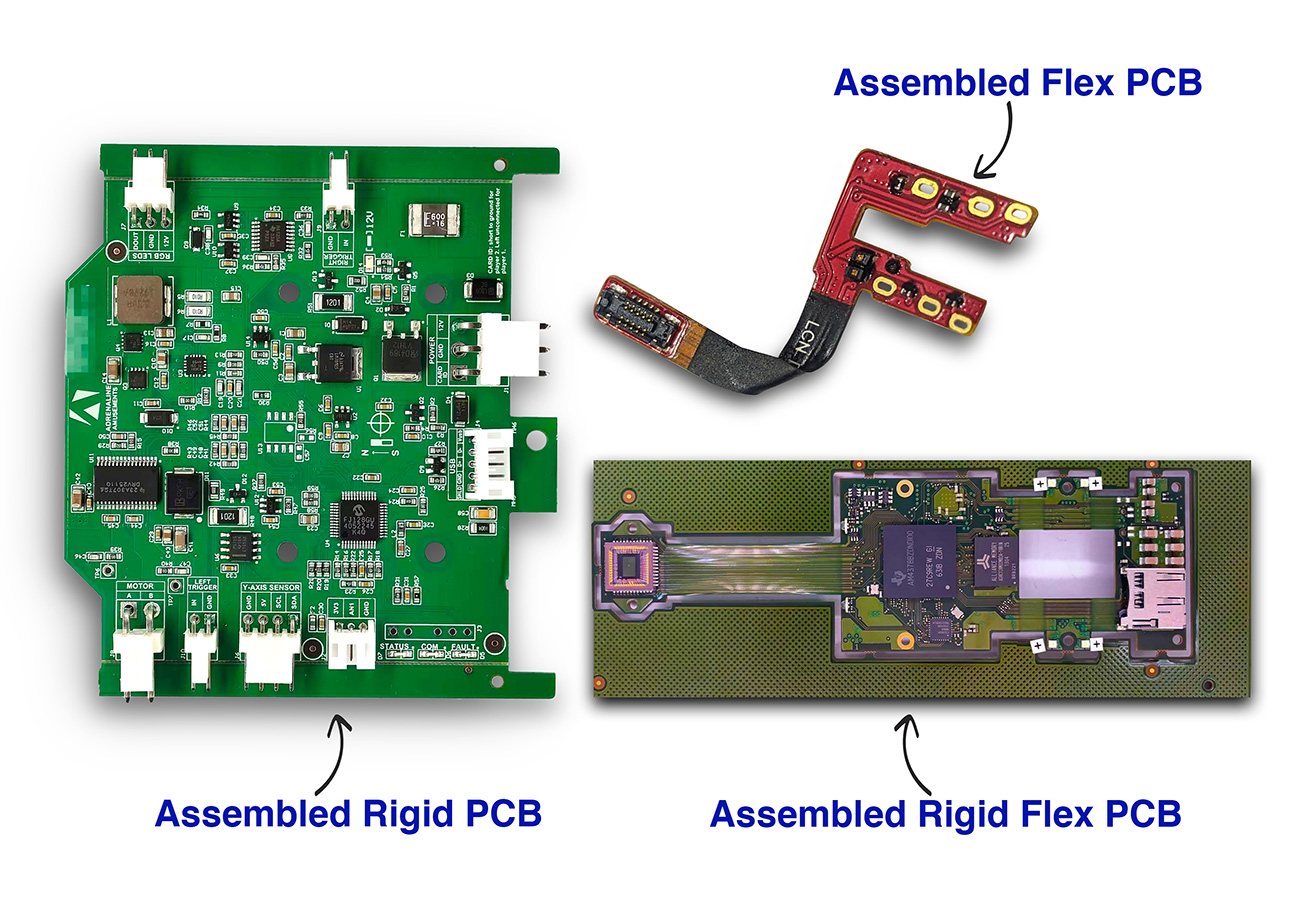

Our PCB assembly capabilities include rigid, flex, and rigid-flex PCBs. Whether your board is in irregular size or has a press fit component, our experienced staff can handle all types of PCB assembly services. Contact the Blind Buried Circuits engineering team at [email protected] today to learn more about our manufacturing and assembly capabilities.

Our Services

- Printed Circuit Board assembly: We have served the industry for decades, making us PCB assembly experts.

- SMT assembly: Our surface mount technology (SMT) assembly speed and efficiency is up matched; with our latest Pick and Place machine capabilities, we provide high-quality and complex assemblies in a quick turnaround.

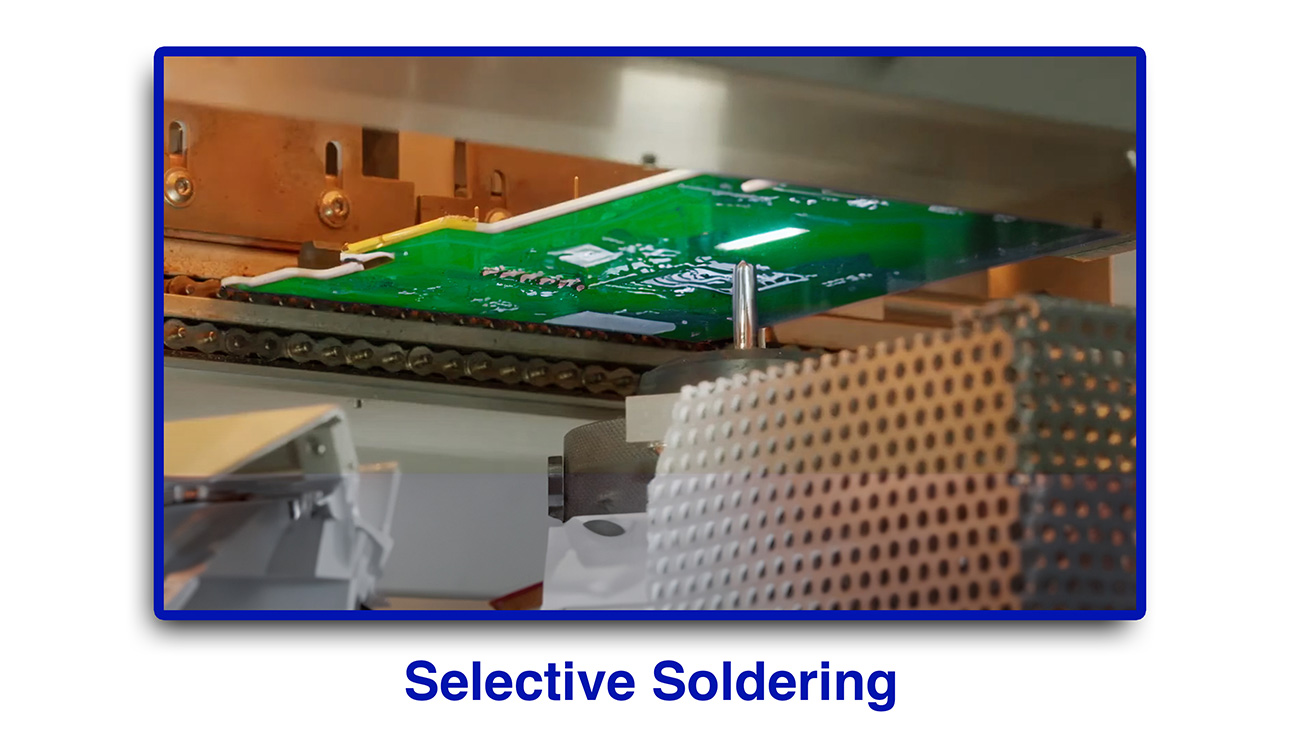

- Through-hole assembly: Our advanced selective soldering machines ensure all the soldering takes place according to IPC Class 2 and 3 quality standards.

- PCB manufacturing and assembly: We are the one-stop shop for your PCB manufacturing and assembly needs with a seamless and efficient process.

- Quick turn assembly: Lead time is vital in product development. We ensure all the deadlines are met and delivered on time to our customers!

Surface Mount Technology (SMT) and Through-Hole PCB Assembly Techniques

Selective Soldering Techniques

- Manual soldering: Our team of experienced technicians can expertly perform manual soldering on your PCBs to ensure proper soldering.

- Reflow soldering: We use state-of-the-art reflow soldering equipment to achieve consistent and reliable soldering results for SMT components.

- Wave soldering: Our process ensures even and precise distribution of solder on your PCBs with through-hole components.

- No-clean process: We offer a no-clean process that leaves no residue on your PCBs and ensures high reliability and performance.

Lead-Free PCB Assembly

PCB Assembly Materials and Components

- Passive SMD components that are as small as 01005 sizes

- BGA, uBGA, POP, QFN, and QFP

- Fine pitch ICs with 0.25 mm (8 mils) pitch

- Various types of connectors and terminals

- Mini stencils printing

Our pick-n-place machines can handle components in different forms, such as reels, cut tape, tubes, or trays. Additionally, for through-hole PCB assembly, we accept loose parts and bulk components.

PCB Assembly Testing and Inspection Techniques

PCB Design for Assembly (DFA) Tips

Are you looking for a quick-turn PCB assembly service?

Get an instant offline PCB assembly quote for assembly labor and bill of Material within 24 hours (BOM must have the quantity, reference designator, manufacturer name, and manufacturer part number).

Once you receive your PCB assembly quote, you can place your order anytime that suits you. So, what are you waiting for? Submit your Gerber and BOM files now to get started.