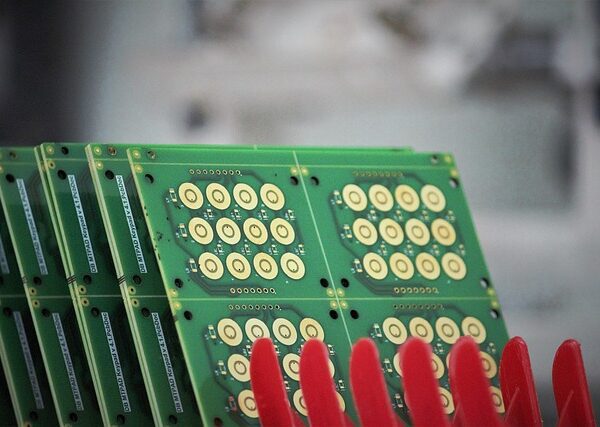

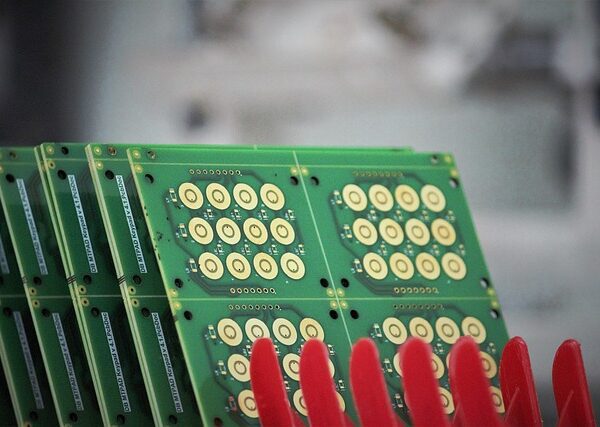

Due to the COVID-19 pandemic and its effects on global supply chains, numerous industries have had to review their manufacturing strategies. The production of printed circuit boards (PCBs) is one such area that has undergone significant changes. In the past few years, PCB manufacturing has increasingly been moved offshore. This is mainly because of lower labour and materials costs and the benefits of economies of scale. Nevertheless, offshore PCB manufacturing poses some advantages as well as challenges.

Mass Production:

Working with offshore manufacturers can be profitable if you need high-volume PCB assembly, as they can often handle large-scale production orders. However, working with a local contract manufacturer is recommended if your product is still in the prototype stage. Numerous changes may be required after the prototype run, and your local CM can provide guidance and invest significant engineering knowledge in finalizing your product. It’s important to consider the potential drawbacks of offshore manufacturing before committing to large-scale production. Unexpected costs and delays can arise, ultimately impacting the project’s success.

Cost-effectiveness:

Offshore PCB manufacturers can be a great option if you want to cut manufacturing expenses without compromising quality. They can offer lower costs due to reduced labour and material expenses and economies of scale. Mass-producing your boards at an offshore facility can lead to significant savings and a better margin on your final product. However, these manufacturers’ automated mass-production systems may need to be more flexible for low-volume or quick production runs, which could cost you more.

Turnaround time:

Choosing an offshore PCB manufacturer can result in faster turnaround times and fewer shipping delays due to their larger capacity. However, it’s important to note that they primarily focus on mass production and may take longer to respond to unexpected needs than local contract manufacturers. Recently, many offshore manufacturers have been unable to deliver boards on time due to unexpected holidays and lockdowns, resulting in delays in production runs.

What difficulties are expected in Offshore PCB Manufacturing?

Offshore PCB manufacturing offers numerous benefits, but it also presents some obstacles. What difficulties can be anticipated in this process? Here are some challenges to consider:

- Long lead times

- Shipping and customs processes can cause significant delays.

- PCBs must be shipped overseas, increasing costs and lead times.

- Shipping costs and times can fluctuate dramatically.

- Time zone differences

- Coordinating meetings and addressing concerns can be difficult.

- Effective communication requires careful planning.

- Language barriers and time zone discrepancies can be challenging.

- Natural disasters and logistical issues

- Delays in PCB shipments can affect production schedules and project deadlines.

- Offshore manufacturing can be impacted by national holidays, political unrest, and unforeseen events like COVID-19.

- High setup expenses

- Offshore manufacturing may not be feasible for prototyping or small-scale production.

- Minimum order quantities and long lead times can be a challenge.

- Limited flexibility

- Offshore production limits flexibility to change design and materials.

- Adjusting to market demands and engineering requirements can be challenging.

It’s best to have local PCB manufacturing, assembly and part procurement for better control and efficiency. This allows for faster communication, design modifications, and prototyping. Companies should balance offshore and local manufacturing to adapt to global markets and respond to unexpected disruptions. Large-volume assembly plants are necessary for mass-production runs, but local manufacturers offer unique services which offshore cannot offer.

Advantages of Choosing Locally Manufactured PCBs

The following are the advantages of choosing locally manufactured PCBs for your upcoming projects:

- Shorter lead times: Local PCBs can be manufactured and delivered much faster than offshore PCBs, as there is no need to ship them overseas.

- Better communication: Working with a local PCB manufacturer allows for easier and more efficient communication, as you can speak to the manufacturer in person or over the phone.

- More flexibility: Local PCB manufacturers are often more flexible than offshore PCB manufacturers, with relaxed minimum order quantities and lead times. This makes it easier to prototype and make design changes.

- Better quality control: Local PCB manufacturers are often more familiar with the materials and processes used in PCB manufacturing, which can lead to better quality control.

- On-site support: If you are geographically close to your local PCB manufacturer, you can work with them on-site to finalize the board development.

At Blind Buried Circuits, we offer all of the above benefits, along with a team of experienced engineers and manufacturing specialists dedicated to providing the best customer service and quality to all our current customers. We have a proven track record of collaborating with inventors and businesses to create new and innovative products.

If you are looking for a reliable and experienced local PCB manufacturer, please contact us today to learn more about our services.

We hope this blog helps you better understand the supply chain process, and feel free to contact us if you have any questions.