Request our manufacturing capability

Capabilities

High TG PCBs

Manufacturing Capabilities For High TG PCBs

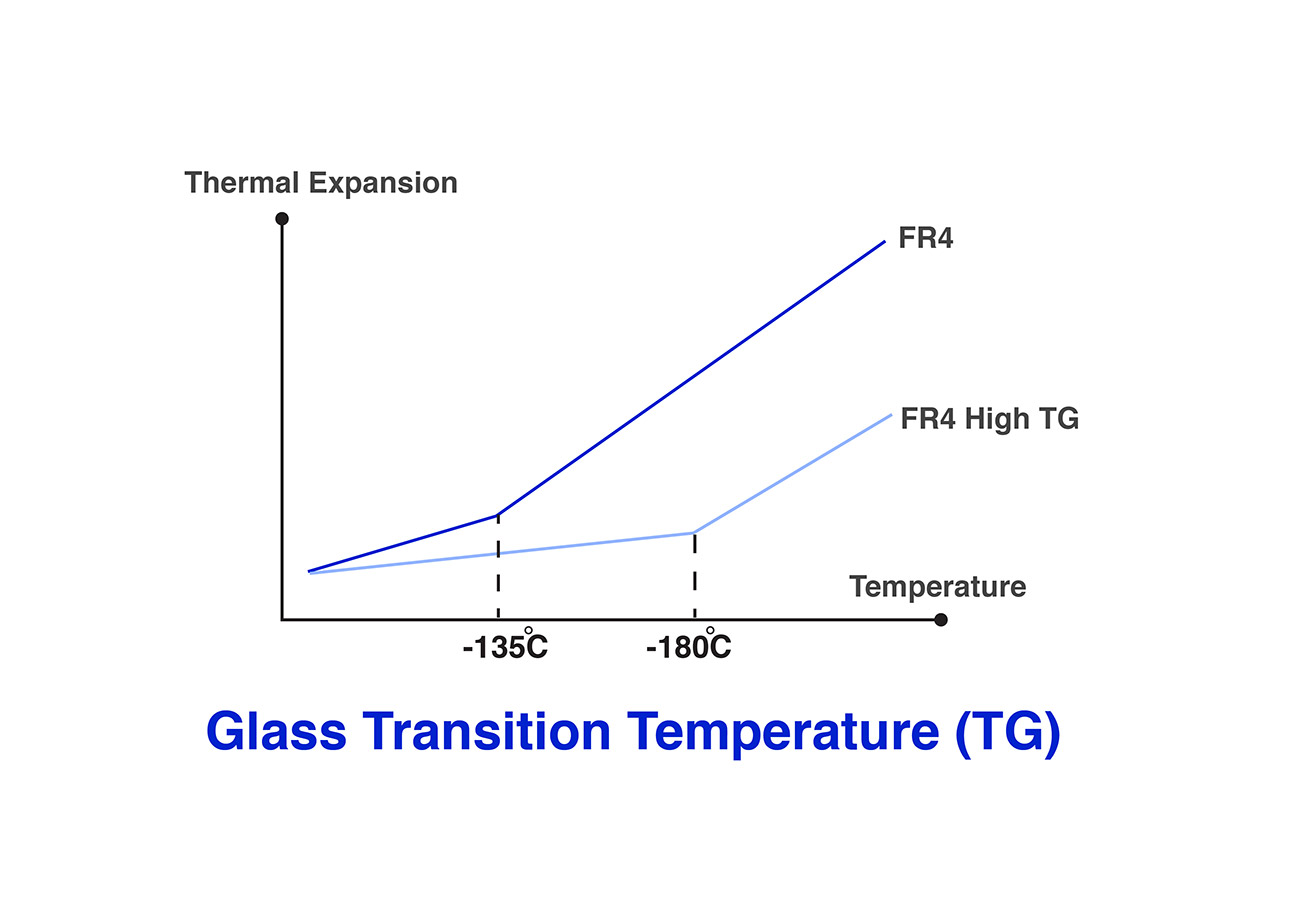

High TG or glass transition temperature PCBs are PCB materials used in high-temperature circuit designs. It provides better heat dissipation as it operates at a higher temperature scale of 150 degrees Celsius. The glass transition temperature can vary depending on the type of material. If the material is 180 TG, it will not change its state to 180 degrees Celsius. If more heat is applied, it will become soft plastic. All the substrates have a temperature above which the material will start soft. Being specialized in High TG PCB manufacturing, Blind Buried Circuits recommends using higher TG material than the operational temperature. It will help fabricate the boards properly and will not change their form upon getting a higher temperature range.

Please fill out our quote form and select the required Hi-TG material for a quick offline quote.

| PCB MATERIAL/SUBSTRATE | |||

|---|---|---|---|

| DESCRIPTION | CATEGORY | STANDARD | ADVANCED |

| High TG | Standard | NP-175, IT-180 TC, IT-180A |

|

| High Speed | ISOLA 370HR, FR408HR, I-Speed, PANASONIC M6, M7, M8 ARLON 85N (PI) |

||

| RF & Microwaves | ROGERS 4350B ROGERS 4003C ROGERS 4450F ROGERS 4835 |

||

What are High-TG (Glass Transition Temperature) PCBs

All the printed circuit boards operating at temperatures of more than 25 degrees Celsius require High-TG PCBs. Almost everyone opts for high TG material due to the lead-free requirement at the PCB assembly. As all the lead-free or RoHS assemblies operate at higher temperatures, if low TG material is placed into the lead-free assembly process, then there are changes of material to change into a rubbery state. The PCB’s material state gets affected, and it also impacts the electrical and mechanical properties of the product.

The material TGs are categorized into three categories:

- Standard TG: Operational temperature is between 130-140 °C.

- Medium TG: Operational temperature is between 150-160 °C.

- High TG: Operational temperature between 170 °C and beyond.

Although standard FR-4 is common in the PCB industry, High-TG PCBs have multiple benefits, including better mechanical properties, greater chemical resistance, and stronger temperature-withstanding capability.

Call us today to quickly get the finest high-Tg boards in the industry.

Advantages Of Using High-TG Material For PCBs

- High resistance to heat.

- Highly reliable for PTH assembly.

- Low Coefficient of Thermal Expansion

- Highly resistive to thermal shocks

- Withstand thermal stress.

- RoHS compliant

- WEEE compliant

- REACH compliant

What Are The Applications Of High-TG PCBs

- Wearable consumer electronics

- Automobile industry

- Industrial products

- Wireless networking devices

- Medical devices

- Optronics applications

- Aerospace and military applications

- Personal computers

What Is Required To Get A Quick Quote For High-TG PCBs

Our quotation process is very simple and fast compared to our competitors. We value our customer time and aim to submit the quotation within 24 hours. To get a quick quotation for high TG PCBs, fill out our quote form and submit Gerber files in 274x format. Our sales team will review the requirements and submit the quote within the committed time frame.