As time passes, most R&D (Research & Development) and OEMs (Original Equipment Manufacturers) come up with several complicated & quick-turn projects requiring fewer time delays and reasonable costs for manufacturing prototypes as per their budgets.

The electronic product developers ensure that their circuits meet the critical project time limit, standards, laws & requirements, and most importantly, the budget to carry forward their designs towards manufacturing.

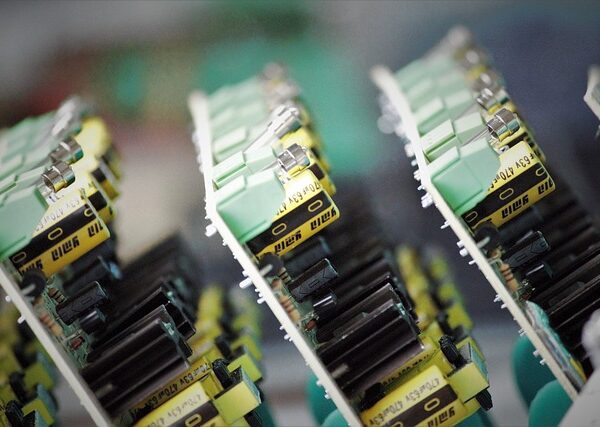

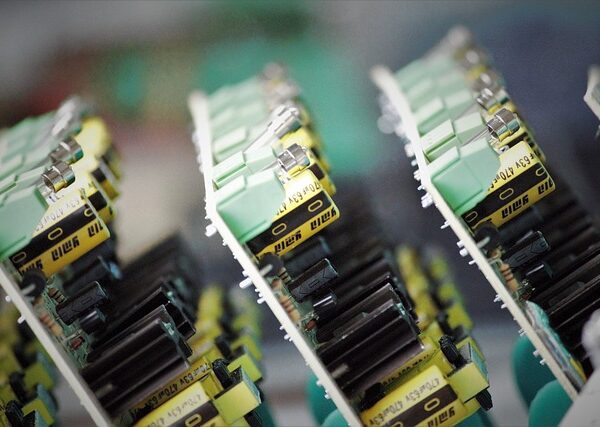

The manufacturing capability of contact manufacturers like Blind Buried Circuits helps design the PCBs. The capabilities include:

- Raw material details (standard and RF materials).

- Layer stack-ups.

- Critical impedance parameters.

- Minimum via hole sizes.

- Guidelines for designing complex circuits like blind and buried.

For that, choosing the right contract manufacturer is mandatory to achieve all these criticalities and to have know-how about manufacturing capability, which help the OEMs and R&D organizations to put their visions on the physical functional circuits.

Advantages of choosing a contract manufacturer of circuit boards:

There are many benefits to choosing a contract manufacturer for your circuit board. Recorded beneath are a couple of significant ones as follows,

-

Critical turnarounds & Production Accuracy:

The most important requirement of electronic manufacturers is the critical turnarounds like 24-hour, 2 days, 3 days lead times. A contract manufacturer can maintain production accuracy in the critical turnaround time by their engineering experts and choose the right production floor for specific designs.

-

Component Sourcing & Assembly:

The electronics components market is volatile due to many research companies now producing critical circuits requiring hundreds of passive & active components for their prototyping & thousands of components for mass production. A few Semiconductor manufacturers run batches of specific integrated circuits (BGAs, FPGAs, SOICs, QFNs, etc) in large quantities once a year. Sourcing all the critical or hard-to-source components is a new challenge for OEMs or R&D companies for which they have the advantage of letting contract manufacturers source the components as per their AVL (Approved Vendor List) to get the parts in hand on time and avoid the time delays in audit prior the PCB assembly.

-

One-stop shop & limited financial investments:

Choosing the one-stop shop is the greatest advantage for electronics manufacturers, OEMs, or R&D companies, to have only one point of contact for their turnkey project, which includes fabrications, components sourcing with different suppliers all over the globe & components placements, or assembly. It saves a couple of days & time as well as efforts and money spent hourly on multiple follow up’s.

As per the advantages mentioned above, if you are looking for PCB capabilities or PCB manufacturing quotations for prototypes or mass production, please do reach with an expert sales engineer for your upcoming projects by submitting the files and details to [email protected] or filling out our quote form to get a quick quotation.