Request our manufacturing capability

Capabilities

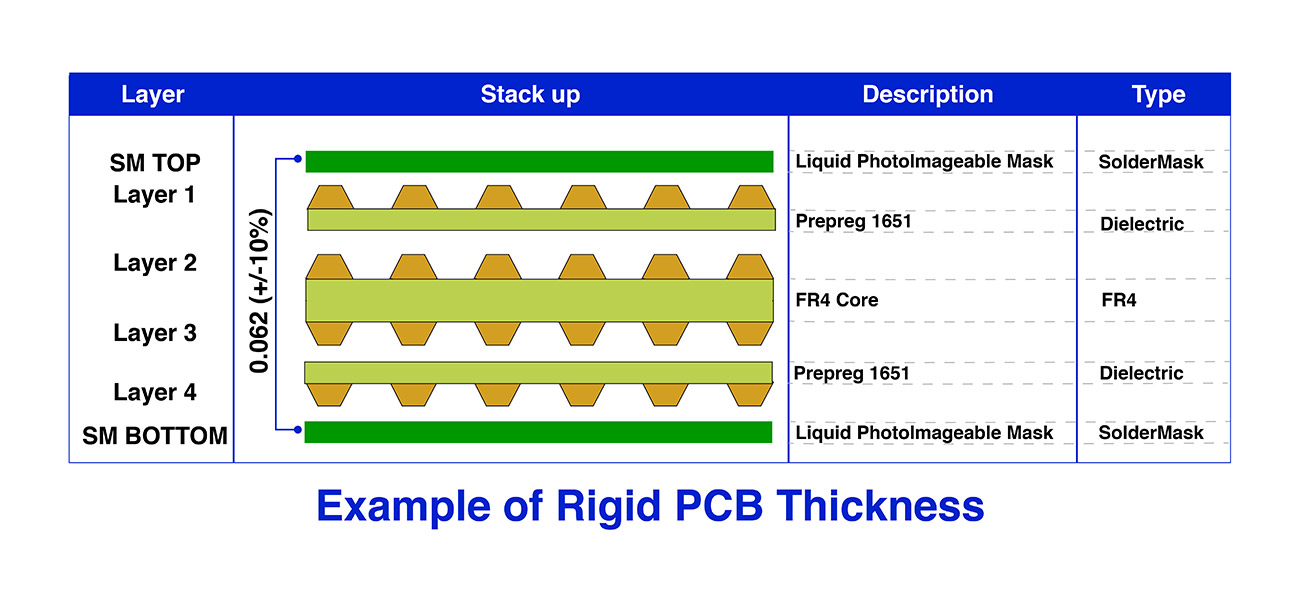

Rigid PCB Thickness

Designing printed circuit boards (PCBs) involves making critical decisions, and one of them is selecting the right board thickness. The thickness of a rigid PCB significantly impacts various factors, including mechanical stability, current capacity, and impedance control. Let’s explore why PCB thickness matters and how it affects your electronic designs.

Mechanical Stability and Heavy Components:

- Thin PCBs: Thin PCBs (with thicknesses typically ranging from 0.4mm to 1.6mm) are suitable for lightweight applications. However, they may lack the structural rigidity needed for heavy components or high-layer-count circuits.

- Thick PCBs: Rigid PCBs with a thickness of around 1.6mm PCB thickness offer greater mechanical stability. They can withstand the weight of components, ensuring the board material remains robust during operation.

Layer Count and Complexity:

- The number of conductive layers affects overall thickness. A 2-layer board will be thinner than a 12-layer board.

- Complex circuits with multiple layers may require thicker PCB load bearing to accommodate the necessary traces, vias, and components.

Copper Thickness and Current Capacity:

- Thicker copper foils (measured in ounces) used for traces and pads impact current capacity. Higher copper layers thickness provides better ampacity.

- Consider the trade-off between copper layers thickness and manufacturing cost.

Material Selection and FR-4 Fillers:

- FR-4 glass epoxy is the most common rigid PCB material. It comes in standard thicknesses (e.g., 0.4mm, 0.6mm, 1.6mm).

- FR-4 fillers enhance PCB Mechanical strength and thermal performance.

Production Cost Considerations:

- Thicker PCBs may be unnecessary and expensive for certain applications.

- Optimize thickness based on your specific requirements.

| OUTER LAYER | ||

|---|---|---|

| DESCRIPTION | STANDARD | ADVANCED |

| Single / Double Sided | Minimum (7.874 Mils) & Max (314.96 Mils) | |

| Multilayer | Minimum (11.81 Mils) & Max (314.96 Mils) | |

| Bow & Twist | 3 to 7/1000 | |

Rigid PCB Thickness for Specific Applications

When selecting the appropriate thickness for rigid PCBs, it is important to consider the specific application and its operating requirements. Rigid PCB thickness, typically measured in inches or mm, directly impacts the board’s mechanical stability, electrical performance, and thermal management. The standard PCB thickness ranges from 0.031 inches (0.79 mm) to 0.125 inches (3.18 mm), with 0.062 inches (1.57 mm) being the most common for general applications. Thinner boards, around 0.031 inches, are often used in compact devices where space and weight are important to maintained, such as in consumer products and handheld electronics. However, thicker boards, up to 0.125 inches, are preferred in applications demanding greater durability and heat dissipation, like automotive, industrial controls, and power electronics. Selecting the correct PCB overall thickness ensures optimal performance, reliability, and longevity of the PCB for its intended application.

The following is a list of the most prevalent applications and economic sectors in which maintaining Rigid PCB Thickness takes important role:

- Consumer Electronics

- Automotive

- Aerospace and Defense

- Industrial Electronics

- Medical Devices

Precision PCB Thickness: Reliability Across Industries

To ensure right thickness of your rigid PCBs is difficult for the performance, reliability, and longevity of your electronic designs. Whether you’re designing a consumer electronics, automotive applications, aerospace and defense, industrial electronics, or medical devices. Our IPC A 600 certified CAM team is here to assist you. We calculate controlled impedance traces width as per the copper oz requirement and apply testing to ensure your designs meet the highest standards.

Do submit your quote request today to our expert sales engineers at sales@blindburiedcircuits.com & aly@blindburiedcircuits.com. Let us help you to achieve the require outcomes in your electronic designs.