Printed Circuit Boards, or PCBs, form the basis of almost all the electronic devices we use-from smartphones to medical equipment. Ensuring that these devices function as intended depends on the thorough testing and inspection of PCBs. Such processes are critical in finding faults and correcting them before the PCB is put into full production or reaches end-users.

Blind Buried Circuits specializes in quick-turn and custom PCB manufacturing, working with the medical, automotive and telecommunications industry. This blog will explain some of the most important testing and inspection methods used in the PCB production line.

Most Popular Top 7 PCB Testing Inspection Methods

The methods utilized in PCB testing can be numerous, and it is usually determined by PCB complexity, the volume of PCBs manufactured, and applications. However, here are seven of the most commonly practiced techniques:

- Visual inspection

Visual inspection is the starting point of PCB quality assurance. The engineers use magnifying tools or automated optical inspection (AOI) systems to look out for obvious defects such as:

- Poor solder joints

- Misaligned components

- Surface scratches

Visual inspection is fast and easy. However, it is usually incorporated with other methods for a deeper assessment.

- In-Circuit Testing (ICT)

In-circuit testing uses a “bed of nails” fixture to test electrical connections on a PCB. The test looks for:

- Circuit continuity

- Component values (such as resistance and capacitance)

- Shorts or open circuits

ICT is a good choice for high-volume production because it delivers uniform and precise results. However, it does require a custom test fixture, which can be costly to develop when low-volume production is expected.

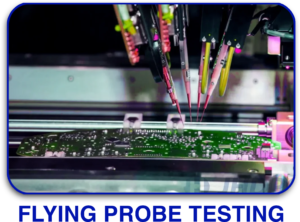

- Flying Probe Testing

Flying probe testing does not use a fixed test fixture like ICT. This makes it a good choice for:

- Small-volume production runs

- Prototyping

- Complex PCBs

Flying probe testing is flexible and cost-effective for low to medium volumes. It is slower than ICT but does not require custom fixtures.

- Functional Testing (FCT)

Functional testing makes sure that the PCB performs as designed in actual situations. The tests check:

- Software compatibility

- Signal processing

- Interaction with other components in a system

For instance, functional testing in medical devices means that the PCB processes data from sensors correctly. This kind of testing is extremely important for applications where both performance and reliability cannot be compromised.

- X-Ray Inspection

X-ray inspection is very important on complex PCBs, especially in cases of blind and buried vias or hidden solder joints. This technique will detect:

- Voids in solder joints

- Layer misalignment in multi-layer boards

- Internal cracks

Using X-ray inspection, engineers can identify hidden flaws that aren’t visible during visual or AOI inspections, making it a vital step for high-density boards.

- Burn-In Testing

Burn-in testing subjects PCBs to extreme conditions, such as high temperatures or voltages, to simulate real-world stress. This helps identify weak components or design flaws that may lead to early failures.

While burn-in testing is long-winded, it’s very important in industries like aerospace, where the application demands the utmost reliability.

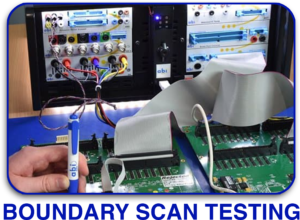

- Boundary Scan Testing

Boundary scan testing applies to compact PCBs, where test points are less in number. It scans the PCB by using the JTAG protocol for signal integrity, communication paths, and logic functions. This scanning is helpful in PCB applications of IoT devices or wearable electronics in which the standard test methods will not work.

Comparison of PCB Testing Methods

| Testing Method | Best For | Advantages | Limitations |

| Visual Inspection | Quick defect detection | Low cost, simple | Limited to visible issues |

| In-Circuit Testing (ICT) | High-volume production | Accurate, consistent | Requires custom fixtures |

| Flying Probe Testing | Prototypes, low-volume batches | Flexible, no fixture required | Slower than ICT |

| Functional Testing | Real-world performance checks | Comprehensive, system-level testing | Time-consuming |

| X-Ray Inspection | Multilayer or HDI boards | Identifies hidden defects | High equipment cost |

| Burn-In Testing | High-reliability applications | Identifies early failures | Time-intensive |

| Boundary Scan Testing | Compact designs, IoT devices | No physical probes needed | Requires JTAG-enabled components |

Why PCB Testing Is Important

Testing and inspection are the backbone of quality assurance in PCB production. A faulty PCB can cause devices to malfunction, requiring costly repairs or even posing a safety hazard. Reliability is very important for industries such as healthcare or aerospace.

No matter how complex or simple your PCB design is, testing ensures that:

- The electrical connections work as intended.

- The components are placed and soldered correctly.

- The board can handle real-world conditions like heat and vibrations.

At Blind Buried Circuits, we include advanced testing with our custom PCB manufacturing so that you can expect reliability and performance in your final product.

How Blind Buried Circuits Ensures Quality

At Blind Buried Circuits, we integrate the testing and inspection methods in delivering high-quality PCBs. Our process ranges from design verification to final assembly, as follows:

- Advanced testing techniques suited to your project.

- ISO and IPC standards for production.

- Custom manufacturing of complex PCBs, especially rigid-flex and HDI boards.

- Whether you have a quick-turn prototype or large-scale production, we are reliable at every stage.

Conclusion

PCB testing and inspection are the steps in the quality assurance process of electronic devices to ensure their reliability and performance. From visual inspections to the more advanced techniques such as X-ray and boundary scan testing, each has its unique role in quality assurance.

At Blind Buried Circuits, we use advanced testing and high-quality custom PCB manufacturing to deliver efficient and reliable solutions for your projects. Whether you require a prototype or high-volume production, we are here to help.