Flex PCBs confront challenges similar to those of other circuit boards, such as electromagnetic (EM) and radio frequency (RF) interference. The interference can affect functioning, resulting in mistakes and total failure at times. Thus, flex circuit board manufacturers need to pay particular attention to the shielding processes in order to deliver sound and reliable flex circuit board products.

This blog will discuss EMI and RF flexible etched circuits that incorporate the most appropriate shielding techniques for flex PCB manufacturer to accomplish their functions, the reasons behind doing so, and the advantages associated with such options.

What is EMI?

Electromagnetic interference (EMI) refers to the interference unwanted electromagnetic signals cause to an electric circuit, impairing its function. These signals are often emitted from other nearby electronic components or wireless devices or sourced from an external environment.

EMI may result in compromised circuit performance, data loss, and, in some cases, total failure of the board. Flex circuit board manufacturers take this seriously when designing flex PCBs to ensure maximum reliability and performance.

What is RF Interference?

RF interference is a type of EMI caused by signals in the radio frequency spectrum. It is just as problematic as EMI, and both can interfere with the proper performance of flex circuit boards by leaking or absorbing unwanted signals.

To overcome such issues, flex PCB manufacturers adopt shielding techniques that enhance the protection of sensitive components, increasing the circuit’s overall reliability.

Reasons for EMI and RF Shielding in Flex PCBs

Signal quality and performance metrics of a circuit are put at risk due to noise. Therefore, proper shielding is required for any application with determined signal processing, such as medical electronics, telecommunications, and aerospace devices. Flex circuit board manufacturers also need shielding for the following reasons:

- Prevent Communication Errors: Enhance Data Integrity.

- Prevent performance interruptions: System Reliability Improvement.

- Support complex electromagnetic conditions: High-Speed Applications.

- Exceed industry EMI standards: Competitor Market Boost.

Methods of EMI and RF Shielding for Flex PCBs

Flex PCB manufacturers use various shielding techniques in order to mask EMI and RF interference. The most common methods are the following:

1. Copper Layers:

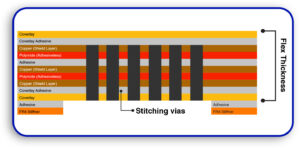

Copper layers provide a durable shielding solution. Based on elements in the design specifications, they can be applied as solid or crosshatched planes. Copper layers are folded over the permanently attached ground layer with vias, creating a complete Faraday cage and blocking interference.

Protection and Isolation Advantages of Copper Layers:

- Certified topping performance

- Useable within controlled impedance projects

- Durable design

Disadvantages:

- Less flexible due to an increase in thickness.

- More expensive.

- Hatched designs may decrease the isolation effectiveness.

- Flex PCB manufacturers often favor copper layers even when other options are available, mainly if signal integrity is an issue.

2. Silver Ink Shielding

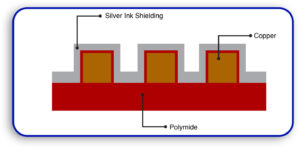

Silver ink is an inexpensive substitute for silver layers. In this case, conductive silver ink is printed onto the flex PCB and then protected with an overlay.

Advantages of Silver Ink Shielding:

- Inexpensive compared to copper layers.

- More versatile.

- Thinner than copper shielding.

Disadvantages:

- Not very effective at high frequency.

- Does not work with every controlled impedance design.

Silver ink tends to be the ink of choice for many applications where cost savings and flexibility are critical.

3. Specialized Shielding Films

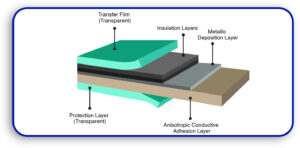

Specialized shielding films consist of a layer of metal deposition, an electrically conductive adhesive, and an insulating outer layer. They are applied to the surface of flex PCBs by lamination using heat and pressure.

Benefits of Shielding Films:

- Thin and lightweight design.

- Highly biocompatible, perfect for dynamic bending.

- Ideal for sensitive applications.

Drawbacks:

- Laminated films are not suitable for controlled impedance.

- Costlier than silver ink.

Shielding films are broadly used in applications where flexibility and shielding from EMI interference are crucial.

How a Flex PCB Should Be Designed While Also Keeping Shielding in Mind

Shielding methods such as that of EMI or RF have various criteria to be met to ensure the flex PCB remains functional and reliable at a high level.

1. Requirement for Bending

Every shielding technique used adds complexity that needs to be managed carefully while increasing the PCB’s overall flexibility. Certain bend types, dynamic and static, also need to be reviewed.

- Static Bending: Designed for movable elements; can afford to be on the thicker side.

- Dynamic Bending: Designed for components that require constant movement; affordable to be thinner and more flexible.

2. Controlling Impedance

Controlled impedance is of utmost importance for high-speed signaling. Materials that need to be employed to shield have to support both EMI shielding and controlled impedance.

Since not every method of shielding allows for controlled impedance, this factor must be considered before selecting the materials. Flex PCB manufacturers need to take this into account during the design phase.

Other Methods of Reducing EMI and RF Interference

In addition to shielding, the use of flex PCBs allows for reduced interference via design options.

- Avoid Sharp Corners: Make use of rounded traces to preserve constant impedance.

- Short Return Loops: Limit current return loops to the most basic form to cut back on loop size.

- Differential Pair Routing: Do not put vias into the differential pairs so that parasitic capacitance can be decreased.

- Ground Plane Design: Ensure the split ground planes are connected at one point.

- Edge Clearance: Recess ground and power planes from the board edges.

Innovative Solutions by Flex PCB Manufacturers

The best flex circuit board manufacturers, including rigid flex PCB manufacturers, focus on innovation to solve the challenges of EMI and RF shielding.

- Advanced Material Combinations: The use of hybrid materials to achieve a good balance of shielding and flexibility.

- 3D Stack-Up Designs: Improved layering methods for minimizing the thickness.

- Automated Assembly Techniques: Better precision and efficiency in shielding material application.

Selecting the proper method of EMI and RF shielding will greatly affect the reliability and performance of flex PCBs. Understanding the strengths and limitations of copper layers, silver ink, and specialized shielding films will enable flex circuit board manufacturers to develop the appropriate solution for their targeted applications.

At Blind Buried Circuits, we want to be one step ahead of the market, so we provide all-around solutions for EMI and RF shielding. We offer a range of services, from deciding which method of shielding is appropriate to meeting advanced design specifications.

If you’re looking for flex PCB manufacturing services, including rigid flex PCBs, don’t hesitate to reach out today. Together, let’s create advanced circuits that are free from interference and optimized for success.