When you get a new electronic gadget, you expect it to work. But behind the scenes, every tiny part of that device goes through testing to make sure it’s safe and reliable. One of the most important ways this happens is with something called flying probe testing. It helps manufacturers find problems in circuit boards before they reach your hands.

Let’s break down how this works and why it matters to you if you’re designing, building, or using electronics.

What Is Flying Probe Testing?

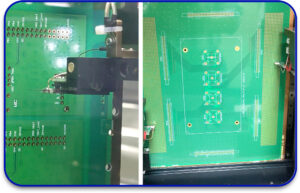

Flying probe testing is a way to check the quality of a printed circuit board (PCB). A PCB is the green board inside most electronics that holds all the essential parts. Instead of using a big, custom-made tool to test each board, flying probe testing uses moving needles, or “probes,” that touch different parts of the board one by one. These probes fly across the board, which is how the method got its name.

A flying probe tester moves these tiny needles using a machine that follows a program based on your board design. This lets the machine check each connection and part of the board without needing special equipment built just for that one design.

Why Flying Probe Testing Is Important in PCB Assembly

When you’re making a product, especially something new or custom, you don’t want to waste time or money. Here’s where flying probe testing really helps:

- Fast for prototypes: If you’re building a few boards to test a new idea, flying probe testing saves you the hassle of building a test jig.

- Suitable for small batches: You don’t have to pay extra for fixtures if you only need a few boards.

- Less risk: It helps catch errors early during the pcb board assembly manufacturing stage.

Whether you’re working with a pcb manufacturer or doing pcb assembly USA style, flying probe testing helps make sure your boards work the first time.

What Can It Test?

Flying probe testing can check for lots of common issues, such as:

- Open connections (when two points that should be connected aren’t)

- Shorts (when two points that shouldn’t be connected are)

- Wrong parts

- Backwards parts

- Missing parts

PCB testers can even check values for resistors, capacitors, and diodes. These checks are part of what’s called a pcb in-circuit test.

When Should You Use Flying Probe Testing?

You should consider flying probe testing when:

- You’re testing a new product

- Your design keeps changing

- You’re making under 100 boards

- You need fast turnaround

For large orders, this method can take too long. But for small jobs, it’s much faster and cheaper than building a full test setup.

How It Works Step by Step

- Create your design: Start with your pcb board design rules and layout.

- Upload to the tester: The flying probe tester reads your files.

- Set test points: These are places on the board where the probes can safely touch.

- Run the test: The probes move around and check each point.

- Review results: The tester reports if anything doesn’t match the plan.

If you use a PCB manufacturer that offers flying probe testing, they’ll do all this for you. Many shops that offer PCB assembly USA services include flying probe testing in the process.

Flying Probe Testing vs. Other Tests

You might wonder how this stacks up against other testing methods. Here’s a simple comparison:

| Test Type | Good For | Needs Special Tools? | Fast? | Best Use |

| Flying Probe | Small runs, Prototypes | No | Medium | Custom boards |

| Bed-of-Nails | Large runs | Yes | Very fast | Mass production |

| Visual Inspection | Basic checks | No | Fast | Simple boards |

So if you’re working on a custom or small project, fly testing with a flying probe system might be your best choice.

Benefits You Can Count On

- No special fixtures: You don’t have to build anything extra.

- Quick setup: Start testing as soon as your board is ready.

- Accurate results: Find mistakes before it’s too late.

- Less cost upfront: Great if you’re trying to save money on early versions.

This makes flying probe testing ideal for people who need results fast and don’t want to build custom tools just for testing.

What to Watch Out For

Flying probe testing isn’t perfect. You should be aware of a few limits:

- It can be slower for big batches.

- It might not catch all kinds of problems.

- If your board doesn’t have clear test points, the setup might take longer.

But for a small run or test batch, the speed and cost savings often make it the best option.

Standard Terms You Should Know

- PCB in circuit test: A way to test the board after all the parts are added.

- PCBA tester: A tool or person who tests a finished circuit board.

- Flying probe tester: The machine that moves the probes around.

- Flying probe testing: The process of testing with movable probes.

- Fly testing: A short term for flying probe testing.

- PCB flying probe test: Another way of saying the same thing.

Final Thoughts

If you want your boards tested quickly without a lot of setup, flying probe testing is the way to go. It helps you find issues early, save money, and get your products to market faster. Whether you’re working on a new idea, a custom project, or just a few boards, flying probe testing gives you peace of mind that everything works as it should. If you’re working with a PCB manufacturer or using PCB assembly USA services, be sure to ask if they offer this kind of test. Using the right test method helps you avoid delays and rework. And that means better products for your customers and less stress for you.

So next time you’re planning a PCB board assembly manufacturing project, remember to include flying probe testing in your checklist. It’s a smart move that can save you time, money, and a lot of headaches later on.