How do advanced electric vehicles (EVs) achieve seamless performance, safety, and intelligence? The answer lies in the integration of sophisticated printed circuit boards (PCBs) throughout every critical system. As EV technology evolves, the demands on PCB manufacturing assembly, custom PCB production, and reliable assembly services have never been higher. This blog explores the pivotal role of PCBs in advanced electric vehicles, the latest trends in EV PCB manufacturing, and how innovations in EV charger PCB assembly services are shaping the future of sustainable transportation.

The Backbone of Electric Vehicles: PCBs

PCBs are the foundation of all modern electronics, and their role in electric vehicles is especially critical. In EVs, PCBs serve as the electrical and communication backbone, linking key components such as the battery management system (BMS), motor controllers, inverters, infotainment systems, and advanced driver-assistance systems (ADAS). Without robust and precisely engineered PCBs, the complex interplay of power, control, and data in an EV would not be possible.

Key Functions of PCBs in Advanced Electric Vehicles

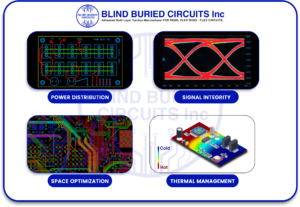

- Power Distribution: PCBs route high-voltage and low-voltage signals between the battery, motor, charging system, and auxiliary electronics.

- Signal Integrity: They ensure fast, reliable communication between sensors, controllers, and user interfaces.

- Thermal Management: Advanced PCB designs help dissipate heat generated by power electronics, protecting sensitive components.

- Space Optimization: Compact, multilayer, and flexible PCB designs allow for efficient use of limited space inside EVs.

- Reliability: High-quality PCBs resist vibration, moisture, and temperature extremes found in automotive environments.

PCB Manufacturing Assembly for EVs: Meeting Unique Demands

The requirements for PCB manufacturing assembly in electric vehicles are far more stringent than those for consumer electronics. EV PCBs must handle high voltages and large currents and operate reliably over long lifespans. This drives the need for specialized materials, advanced manufacturing techniques, and rigorous quality assurance.

Critical Manufacturing Considerations

1. High Voltage and Current Handling:

EV PCBs must be designed to safely manage voltages up to several hundred volts and currents in the hundreds of amps, especially in powertrain and charging systems.

2. Thermal Management:

Efficient heat dissipation is essential. Techniques include using thicker copper layers, thermal vias, and heat sinks integrated into the PCB stack-up.

3. Compact and Complex Designs:

Multilayer PCBs and flexible circuits are used to maximize circuit density and fit into tight vehicle spaces.

4. EMI and Noise Reduction:

Shielding, careful layout, and filtering are crucial to minimize electromagnetic interference that can disrupt sensitive electronics.

5. Automotive-Grade Reliability:

Compliance with standards such as ISO/TS 16949 ensures that PCBs meet automotive quality and safety benchmarks.

The PCB Manufacturing Process

- Design: Schematic capture and layout, accounting for power, signal, and thermal requirements.

- Fabrication: Photolithography, etching, drilling, and plating to realize the circuit design.

- Assembly: Placement and soldering of components, including automated optical inspection (AOI) and functional testing.

- Quality Control: Rigorous testing for electrical, thermal, and environmental performance.

Custom PCB Production: Tailoring Solutions for EV Innovation

No two EVs are precisely alike, and custom PCB production is essential for meeting the unique needs of each vehicle platform. Customization enables manufacturers to optimize board size, shape, layer count, and component selection to fit specific applications, whether it’s a compact BMS PCB or a robust power inverter board.

Advantages of Custom PCB Production

- Optimized Performance: Boards are tailored for specific voltage, current, and thermal demands.

- Space Efficiency: Custom shapes and flexible layouts fit unique vehicle architectures.

- Integration: Embedded sensors, communication modules, and smart features can be added for advanced functionality.

- Faster Prototyping: Rapid design iterations accelerate development and innovation cycles.

PCB Production USA: Supporting Local EV Manufacturing

With the rapid growth of the EV market in North America, pcb production usa has become a strategic advantage. Domestic PCB manufacturing ensures:

- Shorter Lead Times: Faster turnaround from design to delivery.

- Enhanced Quality Control: Easier oversight and compliance with automotive standards.

- Supply Chain Security: Reduced risk of delays or disruptions from overseas suppliers.

- Support for Innovation: Close collaboration between automakers and PCB manufacturers accelerates new product development.

EV PCB Manufacturing: Trends and Technologies

The field of EV PCB manufacturing is advancing rapidly, driven by the need for higher performance, reliability, and sustainability.

Multilayer and HDI PCBs

Multilayer PCBs allow for more circuits in a smaller footprint, vital for the dense electronics in EVs. High-density interconnect (HDI) designs further increase circuit density and enable advanced features like blind/buried vias.

Flexible and Rigid-Flex PCBs

Flexible PCBs are increasingly used in EVs to fit around tight corners and dynamic components. Rigid-flex designs combine the durability of rigid boards with the adaptability of flex circuits, ideal for dashboards, battery packs, and sensor arrays.

Advanced Materials

EV PCBs often use high-temperature laminates, ceramics, or metal-core substrates to withstand the heat generated by power electronics and fast charging.

Embedded Components

Embedding passive and active components within the PCB itself saves space, reduces weight, and improves reliability, key for automotive applications.

Sustainability

Eco-friendly materials and processes are gaining traction as automakers seek to reduce the environmental footprint of EV production.

PCBs in Advanced Electric Vehicles: Applications and Impact

PCBs are present in nearly every subsystem of an advanced EV, including:

- Battery Management Systems (BMS): Monitor and balance cell voltages, manage charge/discharge cycles, and ensure safety.

- Power Inverters and Motor Controllers: Convert DC battery power to AC for the motor, with precise control and high efficiency.

- Charging Systems: Manage AC/DC conversion, communication with charging stations, and safety features.

- Infotainment and Connectivity: Support displays, audio, navigation, and wireless communication.

- ADAS and Safety Systems: Integrate sensors, cameras, and control units for features like collision avoidance and autonomous driving.

- Thermal Management: Control fans, pumps, and sensors to maintain optimal operating temperatures.

EV Charger PCB and Assembly Services

As EV adoption grows, the need for reliable and efficient charging infrastructure is critical. EV charger pcb and EV charger pcb assembly services are at the forefront of this evolution6.

Key Functions of EV Charger PCBs

- Power Conversion: Manage high-power AC/DC conversion for fast, efficient charging.

- Communication: Enable secure data exchange between the vehicle and the charging station.

- Safety and Protection: Integrate circuits for overcurrent, overvoltage, and thermal protection.

- User Interface: Support displays, indicators, and connectivity features.

Assembly Services for EV Charger PCBs

- Component Placement: Automated assembly ensures precise placement of capacitors, resistors, controllers, and communication modules.

- Soldering and Inspection: High-quality soldering and AOI guarantee reliability and safety.

- Testing: Functional and compliance testing ensures every charger PCB meets industry standards.

- Scalability: Assembly lines are designed for both prototyping and mass production, supporting the rapid growth of charging networks.

Future Directions: Innovation in EV PCB Manufacturing

Ongoing advances in materials, processes, and automation shape the future of EV PCB manufacturing.

- Wide-Bandgap Semiconductors: Materials like SiC and GaN enable higher efficiency and faster switching in power electronics.

- 3D PCB Printing: Additive manufacturing techniques promise faster prototyping and new design possibilities.

- Increased Automation: Robotics and AI-driven inspection are reducing costs and improving quality in PCB assembly.

- Smart PCBs: Integration of sensors and communication modules enables real-time monitoring and predictive maintenance.

Conclusion: Powering the Electric Vehicle Revolution

The integration of PCBs in advanced electric vehicles is fundamental to the performance, safety, and intelligence of modern transportation. From battery management to charging infrastructure, every innovation in PCB manufacturing assembly, custom PCB production, and EV charger PCB assembly services drives the EV industry forward. As materials, manufacturing techniques, and design practices continue to evolve, PCBs will remain at the heart of the electric vehicle revolution, enabling a cleaner, smarter, and more connected future.