How do fiber optic networks achieve their legendary speed, reliability, and scalability? The answer lies not only in the glass fibers themselves but also in the sophisticated printed circuit boards (PCBs) that connect, manage, and power every node in the network. As fiber optic network infrastructure expands to meet the world’s growing data demands, strategic PCB acquisition, especially from advanced flexible printed circuit manufacturers and rigid-flex PCB manufacturers, has become a cornerstone of successful network deployment.

This blog explores how PCB sourcing, production, and integration support robust fiber optic network design and why working with the right partners in PCB production usa is essential for future-ready connectivity.

The Critical Role of PCBs in Fiber Optic Network Infrastructure

Fiber optic networks rely on light signals to transmit data at incredible speeds over long distances. However, every interface, whether it’s a transceiver, multiplexer, router, or switch, requires electronic control, signal processing, and power management. This is where fiber optic PCB solutions come into play.

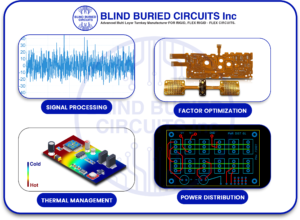

Key functions of PCBs in fiber optic systems:

- Signal Processing: PCBs host the electronic circuits that convert optical signals to electrical and vice versa.

- Power Distribution: They manage power delivery to lasers, photodetectors, and control logic.

- Thermal Management: Advanced PCB designs help dissipate heat from high-speed components.

- Form Factor Optimization: Flexible and rigid-flex PCBs enable compact, high-density layouts in transceivers and network cards.

Without robust, precisely engineered PCBs, the performance and reliability of fiber optic network infrastructure would be severely compromised.

Understanding PCB Types for Fiber Optic Applications

Fiber optic hardware often demands more than standard rigid boards. Here’s why flexible printed circuit manufacturers and rigid-flex PCB manufacturer partners are so important:

- Flexible PCBs: These are used in tight spaces, such as SFP (Small Form-factor Pluggable) modules, where traditional rigid boards can’t fit. Flex circuits allow for bending and folding, making them ideal for compact optical transceivers and patch panels.

- Rigid-Flex PCBs: These combine the mechanical strength of rigid boards with the versatility of flex circuits. They are perfect for devices that require both durability and space-saving layouts, such as high-density fiber distribution hubs.

- Multilayer Rigid PCBs: Used in core network switches and routers, these boards provide the high layer counts and controlled impedance needed for high-speed data transmission.

Selecting the right PCB type is a foundational step in fiber optic network design.

The PCB Manufacturing Process: Precision and Quality

The journey from design to finished PCB is both complex and highly precise. For fiber optic applications, every step must meet stringent quality and performance standards.

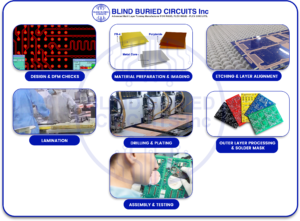

Key manufacturing steps include:

Design and DFM Checks:

The process starts with schematic capture and layout, followed by Design for Manufacturability (DFM) checks to catch potential issues before fabrication begins.

Material Preparation and Imaging:

High-quality laminates and copper foils are prepared. A photoresist is applied, and the circuit pattern is imaged onto the copper using ultraviolet light, hardening the areas that will form the traces.

Etching and Layer Alignment:

Unwanted copper is chemically etched away, leaving only the designed traces. For multilayer boards, each layer is optically aligned and inspected to ensure perfect registration.

Lamination:

Layers are stacked and fused under heat and pressure, creating a solid, multilayer structure. This is especially critical for high-speed fiber optic PCB designs, where signal integrity depends on precise layer alignment and bonding.

Drilling and Plating:

Holes for vias and component leads are drilled with high precision and then plated with copper to ensure electrical connectivity between layers.

Outer Layer Processing and Solder Mask:

The outer layers are imaged, etched, and coated with a solder mask to protect the copper and define solderable areas.

Assembly and Testing:

Components are placed and soldered, followed by automated optical inspection (AOI) and functional testing to verify performance.

For fiber optic applications, advanced inspection and testing are non-negotiable. Even minor defects can cause significant signal loss or reliability issues in high-speed networks.

Sourcing Strategies: Why PCB Production USA Matters

With global supply chains under pressure, sourcing PCBs from PCB production usa offers several strategic advantages for fiber optic network projects:

- Shorter Lead Times: Domestic production enables rapid prototyping and faster delivery, which is crucial for large-scale network rollouts.

- Quality Assurance: U.S. manufacturers adhere to strict quality and environmental standards, reducing the risk of defects or compliance issues.

- Supply Chain Security: Local sourcing minimizes disruptions from geopolitical events or shipping delays.

- Collaboration: Proximity allows for closer engineering collaboration, design iterations, and on-site support during installation or troubleshooting.

Choosing a U.S.-based rigid flex pcb manufacturer or flexible printed circuit manufacturer can be the difference between a smooth deployment and costly delays.

Key Considerations for Fiber Optic PCB Acquisition

To support robust fiber optic network infrastructure, organizations must adopt a strategic approach to PCB acquisition:

1. Partner Selection

Work with manufacturers who specialize in high-speed, high-density PCBs and who understand the unique demands of fiber optic hardware. Look for experience in both flexible and rigid-flex technologies.

2. Design for Manufacturability (DFM)

Early DFM engagement helps catch issues that could impact performance or manufacturability, reducing costly redesigns and delays2.

3. Material Selection

High-frequency laminates and low-loss dielectrics are essential for maintaining signal integrity in fiber-optic PCB designs.

4. Advanced Testing

Insist on comprehensive testing, including AOI, X-ray inspection, and functional tests at gigabit speeds.

5. Scalability

Choose partners with the capacity to scale from prototypes to volume production, ensuring consistent quality throughout the project lifecycle.

Fiber Optic Network Design: The PCB Perspective

A successful fiber optic network design integrates PCB considerations from the outset. Here’s how:

- Transceiver Modules: Compact, high-speed PCBs with tight impedance control and minimal signal loss.

- Network Switches and Routers: Multilayer boards with advanced power distribution and thermal management.

- Patch Panels and Distribution Frames: Flexible and rigid-flex PCBs for space-saving, reliable connections.

- Monitoring and Control Units: Boards with integrated sensors and communication interfaces for remote diagnostics.

By aligning PCB acquisition with overall network design goals, organizations can ensure optimal performance, reliability, and upgradeability.

The Future: Innovation in Fiber Optic PCB Technology

As bandwidth demands grow and networks become more complex, PCB technology is evolving rapidly:

- Higher Layer Counts: Supporting more channels and higher data rates.

- Advanced Flex Materials: Enabling tighter bends and more reliable flex circuits for next-generation transceivers.

- Embedded Optics: Integrating optical components directly onto PCBs for even greater miniaturization.

- Green Manufacturing: Eco-friendly materials and processes are becoming standard, especially among U.S. producers.

Conclusion: Strategic PCB Acquisition for Next-Gen Fiber Networks

Fiber optic networks are only as strong as the PCBs that power and connect them. By partnering with leading flexible printed circuit manufacturers and rigid-flex PCB manufacturers and by leveraging the advantages of PCB production usa, organizations can build fiber optic network infrastructure that is fast, reliable, and ready for the future.

Whether you’re designing core switches, compact transceivers, or distribution panels, make PCB acquisition a strategic priority. The right boards, sourced from the right partners, will ensure your fiber optic network delivers on its promise of world-class connectivity.