High-Density Interconnect (HDI) PCBs have changed the way electronic devices are built. These circuit boards are compact but powerful. If you’re working with small, high-performance electronics, you need to understand what HDI PCBs can do for you.

Did you know? HDI technology is used in 90% of smartphones and advanced electronic devices today. It’s not just about size, it’s about speed, power, and performance. Whether you’re a custom PCB manufacturer or considering custom PCB production, knowing how HDI-printed circuit boards can improve your designs is key.

What Are HDI PCBs?

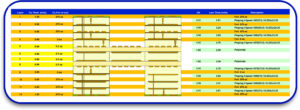

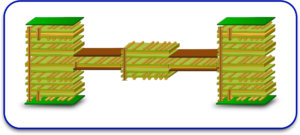

HDI PCBs, or High-Density Interconnect printed circuit boards, are boards with more components packed into smaller spaces. They use finer lines, smaller vias (the tiny holes connecting different layers), and advanced layout techniques.

Unlike traditional boards, HDI PCB boards are built to manage more connections in less space. You’ll often find them in phones, tablets, wearables, cameras, and even medical and military equipment.

The Need for Compact Power

Today’s electronics are getting smaller. You want a slim phone, a lightweight laptop, or a tiny medical device that fits in your pocket. But at the same time, these devices must do more faster. HDI PCBs allow you to shrink the size of the product without losing performance, and this is where HDI PCB design shines. For a PCB board manufacturer or designer, the ability to include more functions in a smaller footprint means better products and lower costs in the long run.

Key Advantages of HDI PCBs

Let’s break down the top reasons why HDI-printed circuit boards are the right choice for your next project.

1. Smaller Size, Better Performance

HDI boards are built to fit in small spaces. But they don’t just save space; they improve performance too. Shorter paths between components lead to faster signal transmission.

So, if your product demands speed and reliability, HDI helps you achieve them without taking up more space.

2. Better Signal Integrity

HDI boards reduce electrical noise. Since the components are closer together, the signals have to travel shorter distances, lowering the chance of signal loss or distortion.

When you care about signal quality, especially in sensitive medical or communication devices, HDI helps you stay sharp and clear.

3. Fewer Layers, Lower Cost

Yes, custom PCB production can be costly especially for advanced designs. But here’s the good news: with HDI, you can reduce the number of layers needed.

Because of a better layout and more connections per layer, you might achieve the same results with fewer layers. Fewer layers mean lower production costs and easier assembly.

4. High Reliability

When you invest in HDI PCB boards, you’re building for the long term. These boards are made using quality materials and advanced techniques, giving them high durability.

This is critical for medical or industrial products. You don’t want your device to fail under pressure.

Where HDI PCBs Are Used

You may be surprised how many devices around you use HDI. Here are just a few areas:

- Smartphones and Tablets

- Every inch counts. HDI helps pack in processors, cameras, and memory without making your device bulky.

- Medical Equipment

- Devices like pacemakers or imaging machines need precision and reliability. HDI PCB design ensures both.

- Wearables and Smartwatches

- Tiny devices need potent boards. HDI lets designers include more tech in less space.

- Automotive Electronics

- Modern vehicles have sensors, GPS systems, and entertainment features all using advanced PCBs.

If you’re a PCB board manufacturer trying to meet modern needs, these applications show where HDI gives you an edge.

Custom PCB Production for HDI

If you’re starting a project with complex needs, you’ll want a custom PCB manufacturer who understands HDI technology.

Why? Because HDI boards require precision. You need tight tolerances, clean vias, and high-quality materials. This isn’t something just any fabricator can handle.

Look for a partner with experience in HDI PCB board builds. Ask them about their design support, manufacturing capabilities, and testing methods. It’ll save you time and money.

Challenges to Keep in Mind

While HDI offers many benefits, there are also some challenges you should know about.

1. Design Complexity

HDI designs aren’t simple. You’ll need to consider signal integrity via placement, heat management, and component spacing. But with a good design tool and an experienced team, you can manage them well.

2. Cost for Prototyping

At first, HDI prototypes might seem more expensive. That’s because of the detailed process and materials needed. However, the benefits often outweigh the upfront cost.

If you’re aiming for large production later, this early investment makes sense.

3. Advanced Equipment Needed

Not every factory can build HDI. The equipment for custom PCB production or PCB production USA must support laser drilling, fine-line etching, and advanced inspection.

Always work with a custom PCB manufacturer that’s fully equipped for HDI work.

Design Tips for HDI PCBs

To get the most from your HDI board, here are some tips to keep in mind:

- Use Microvias: They allow more routing space on each layer.

- Plan the Stackup Early: Choose the correct number of layers and materials for better signal flow.

- Watch Trace Widths: Thinner lines help with space, but need careful handling to avoid signal issues.

- Focus on Thermal Management: With tight layouts, heat can build up fast. Use vias and copper pours to manage it.

- Test Often: Prototypes and simulations help catch errors before full production.

These tips help ensure your HDI PCB design meets both quality and performance goals.

How HDI Fits Into the Future of Electronics

The electronics world is only getting faster and smaller. That means HDI-printed circuit boards are no longer just nice to have they’re necessary. If you’re planning ahead, adopting HDI PCB design now will keep you competitive and prepare you for new challenges and customer needs. Whether you’re in consumer electronics, healthcare, defense, or automotive, HDI gives you the tools to deliver better products.

Final Thoughts

In today’s fast-moving electronics world, space and performance matter more than ever. HDI PCBs offer both.

If you’re a PCB board manufacturer or someone planning a new product, now is the time to look into HDI printed circuit boards. With benefits like improved speed, better reliability, and reduced size, they make your designs smarter and more efficient. And if you’re focused on custom PCB production or working with a custom PCB manufacturer, be sure to choose one with real HDI experience. Whether you’re building wearables, smart gadgets, or mission-critical medical gear HDI PCB boards help you build better.