As the printed circuit board (PCB) industry evolves, the need to guarantee the quality and reliability of PCB assemblies becomes increasingly critical. Every flaw, however small, can cause a product to fail, leading to monetary and reputational losses. To achieve the desired quality, PCB assembly manufacturing processes contain thorough inspection techniques. Structured PCB assembly inspection reports allow manufacturers to manage and document quality procedures for compliance with standards.

This blog discusses the formats of the PCB board assembly manufacturing inspection report, covering the essential parts, their relevance, and recommendations on how to execute them best.

Assistance with a PCB Assembly Inspection Report

To improve the general product quality, a PCB assembly company will inspect at many different levels of the manufacturing process. The inspection report has the following general purposes:

- Verification of Specifications: It assists manufacturers in confirming that every single PCB produced meets the needed conditions.

- Monitoring and History of Problems: Provide evidence of recurring issues that help raise questions about which processes can be improved.

- International Compliance: Guarantees compliance with IPC-A-610 as well as ISO 9001.

- Guarantee to Customer: Statutorily proves quality control documented.

- Improved Productivity: Aids PCB manufacturing assembly teams to perfect production procedures for increased efficiency.

Adhering to a defined structure of the circuit board inspection report enables firms to enhance the reliability and durability of their products.

Important Sections of a PCB Assembly Inspection Report

Like every report, many sections on the PCB report communicate different parts of the review steps processed. Findings obtained, and the steps that need to be taken afterward. Here’s a detailed breakdown:

1. Summary of Inspection

This portion will give an outline of the assembly board that was evaluated. It brings to light:

- PCB Part Number: It is the number that uniquely identifies the board.

- Manufacturer Name: It is the PCB assembly company that makes the part.

- Inspection Date And Time: Used to check the quality control procedures.

- Inspector Details: The name and title of the person who did the inspection.

- Inspection Type: States the inspection method, whether it was manual, automatic or other form of measurement.

2. Results Of Visual Inspection

An initial set of tasks in the circuit board inspection will always include manual visual inspections. Experienced inspectors look for:

- Accuracy of Component Placement: Making sure all components are placed in the appropriate areas.

- Solder Joint Quality: Cold joint soldering, bridging, and too little soldering are all signs that need to be identified.

- PCB Surface Condition: Look for contaminants, scratches, or cracks.

- Orientation And Polarity: Make sure that polarized parts that are placed are in their appropriate positions.

3. Automated Optical Inspection (AOI) Report

The AOI analysis for the PCB employs high-quality cameras and functions on a system that detects discrepancies using machine learning. This subsection consists of the following:

- Solder Joint Analysis: Determines possible risks in soldering processes.

- Component Misalignment: Indicates any misplaced or rotated components.

- Short Circuits & Open Circuits: Recognizes problems in electric voltage supply.

- Presence of Foreign Objects: Spots dust, foreign particles, and misplaced solder.

4. Functional Testing Results

Functional testing establishes the operation of the PCB as expected. This subsection reports on:

- Power-On Tests: Measures voltage levels and power intake.

- Signal Integrity Checks: Ensures effectiveness of data transmission without interference.

- Connectivity Verification: Check the correctness of electric connections in the circuit.

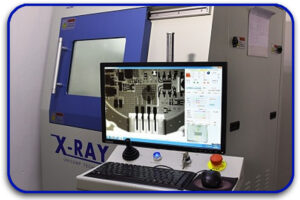

5. X-Ray Inspection Report

For dense PCBs, such as the HDI (High-Density Interconnect) boards, a PCB X-ray inspection is done that looks over:

- Hidden Solder Joints: Find discrepant soldering in BGA (Ball Grid Array) components.

- Inner Layer Defects: Recognition of micro cracks and misalignment in multilayered boards.

- Solder Voids: Gaps within the solder joints that are not filled with solder and will lead to weak connections.

6. Defect Classification & Severity Analysis

This subsection allocates defects into three classes:

- Critical Defects: Problems with the board that will render it unusable or unsafe under normal conditions.

- Major Defects: Degradation of performance that can be fixed.

- Minor Defects: Functional unsightliness.

Corrective actions and recommended procedures for handling each defect are noted.

7. Process Control Metrics

In the pursuit of better manufacturing quality, the inspection report may incorporate some process control metrics like:

- First Pass Yield (FPY): Punctuality of passive elements of PCBs without any adjustments.

- Defect Rate: Measurement of undiagnosed errors in produced units.

- Mean Time to Failure (MTTF): How long the PCB is supposed to last.

- Rework Rate: Adjustments made on PCBs or the units retaken for remediation.

8. Compliance and Certification Status

This section is relevant in verifying if the PCB assembly company complies with industry standards set below:

- IPC-A-610: Expectation for accepting Circuit Board Assemblies.

- ISO 9001: Registered for Quality Management System Standard.

- RoHS Compliance: Use of materials other than lead.

- UL Certification: Approval of safety and flammability tests.

9. Final Approval and Sign-Off

In the last stage before shipment or device integration, the PCB assembly must obtain the final sign off:

- From the Quality Assurance Team.

- Final signatures from the inspectors and supervisors.

- A summary of findings on the conducted inspection.

Types of PCB Inspection Methods Used in Manufacturing

1. Visual Inspection

- Positioning of people with the help of a microscope or magnifying glasses.

- Best for large error types like components that are absent.

2. Automated Optical Inspection (AOI)

- Employs cameras and algorithms to find defects in soldered joints and misplaced assemblies.

- More rapid and uniform outcome for inspection compared to human inspection.

3. X-Ray Inspection

- Used for inspecting hidden attributes of BGA Components and multi-layer PCBs.

- Important for circuits of HDI boards and in case of high-density assemblies of intricate designs.

4. Functional Testing

- Checks the electronic functionality of the product in the field.

- Confirms the effective working of the PCB in question prior to embarking on mass production.

5. In-Circuit Testing (ICT)

- Applies electrical probes to every node of a circuit for verification.

- Detects open circuits, shorts, and faulty components.

Learn About : The Critical Methods in PCB Testing and Inspection

The General Principle Of Collecting Information For PCB Inspection Report Submission

To properly document records and control the defects so that none is missed, manufacturers should do the following:

1. Standardized Report Formats

- Adopt templates so that no alteration is made to the format.

- Incorporate diagrams, graphs, and pictures to capture the audience.

2. Real-Time Data Logging

- Designed collection of data storage to ensure the accuracy of the information collected.

- Minimizes the chances of manually entered data inaccuracies and improves document traceability.

3.Clear Defect Descriptions

- Issue-specific defect codes (for example, Solder Bridge – SB01).

- Accompany narrative descriptions and the solution offered.

4. Digital Storage & Accessibility

- Access stored records via the net.

- Make it possible for other teams to use the information via the internet.

5. Regular Audits and Reviews

- Periodically check the reports to enhance quality management.

- Analyze recurring mistakes for inspection procedure adjustments.

The inspections that have been conducted and documented through the PCB assembly inspection report serve as the basis for the evaluation of the manufacturing process and its quality. It offers a systematic approach to documenting defects, measuring output levels, and capturing compliance with set standards. Including inspection procedures for circuit boards like AOI inspection PCB, X-ray inspection, and functions tests enable more excellent reliability and customer satisfaction on product goods from PCB manufacturing assembly teams.