When you’re building anything electronic,a phone, a control panel, or even a medical device,one thing matters most: every connection must work right, every time. That’s where the IPC J-STD-001 standard steps in. If you’re involved in PCB manufacturing and assembly, you can’t afford to overlook it.

What Is IPC J-STD-001?

IPC J-STD-001 is a standard used around the world to guide the soldering of electronic parts. Think of it as a detailed rulebook that shows how to make reliable soldered joints. This standard is not just for one type of product. It’s used in everything from consumer electronics to military equipment.

The goal is simple: help you build PCBs that last and perform well, even under stress. Whether you work in a large PCB manufacturing company or you’re just starting with small projects, this standard matters.

Why Should You Care About This Standard?

If you’re involved in PCB manufacturing or assembly, understanding and following the IPC J-STD-001 standard is crucial. Here’s why it matters to you and your business:

1. Avoid Problems and Increase Safety

This standard helps you avoid common issues like product failures, returns, or even safety hazards. By following IPC J-STD-001, you’re ensuring that your products are built to last and perform safely.

2. Improve Product Quality

One of the most significant benefits of this standard is that it teaches you how to solder correctly. High-quality soldering means fewer defects, stronger connections, and more reliable boards. This directly translates to happier customers and fewer complaints.

3. Build Trust with Clients and Partners

When your products meet global standards, clients and partners trust your work more. It shows that you care about quality and consistency, which can lead to long-term business relationships.

4. Reduce Waste and Save Money

Mistakes in PCB assembly can be costly, leading to scrapped boards and wasted materials. By following clear guidelines, you minimize errors and reduce waste, saving both time and money.

5. Standardize Your Process

Having a clear set of rules means everyone in your team knows what to do and how to do it. This consistency ensures that every board, every joint, and every connection is made correctly.

Why Is Consistency Important in PCB Manufacturing?

In PCB manufacturing and assembly, consistency is key. You want every board to work flawlessly, regardless of when or where it was made. Following IPC J-STD-001 helps maintain that consistency, boosting both quality and efficiency.

What’s Inside the IPC J-STD-001 Standard? To understand how this standard helps, here’s a quick breakdown of its core elements:

- Materials: Specifies the type of solder and flux to use. Using the right materials ensures reliable connections.

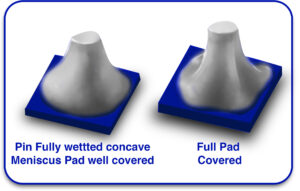

- Workmanship: Defines what a good solder joint looks like. Clear criteria help your team know what’s acceptable.

- Processes: Guides you on how to manage heat, timing, and cleaning during assembly. Controlling these factors reduces errors and improves quality.

- Testing: Provides methods to inspect and test solder joints. This means you can catch problems early, before they reach your customers.

By following IPC J-STD-001, you set up a reliable process in your PCB assembly manufacturing. It’s not just about meeting a standard,it’s about ensuring quality, safety, and efficiency in every product you make.

It Helps Different Industries

This standard isn’t just for one field. You can find it in:

- Consumer electronics

- Medical devices

- Automotive systems

- Aerospace and defense

Each of these industries needs strong, reliable PCBs. If you’re making medical devices or flight systems, your boards must never fail. J standard soldering helps you get there.

What Is J-STD Soldering?

It’s a set of rules and skills. It shows how to:

- Place components correctly

- Use the right amount of solder

- Heat the joints evenly

- Clean and inspect your work

If your joints look good but fail under stress, you need this training. The standard helps avoid cold joints, cracks, and bad connections.

This is where a lot of manufacturers go wrong. They skip the steps. They rush the soldering. Later, they see cracks, poor current flow, or total board failure. J std soldering stops these problems early.

What Is J-STD Soldering Certification?

If you want to show your skills, you can earn a certificate. This proves you understand and apply the rules of IPC J-STD-001. Certification helps you:

- Get hired: Companies want trained workers.

- Earn more: Certified workers often make more.

- Improve your skills: You learn what works and what doesn’t.

- Gain trust: Clients know you follow the best practices.

Many training centers offer these classes. Ask your employer or check online if you want to enroll. It’s a significant step if you work in PCB manufacturing, assembly, or repair.

What About Companies?

It’s not just for people. Companies can also be certified to follow the IPC J-STD-001 standard. That means your factory and team meet high standards.

For a PCB manufacturing company, this is a big plus. It helps win contracts, grow your brand, and show you take quality seriously.

Clients in medical, military, or aerospace fields often demand this certification. If you’re not certified, you may lose their business.

How Does This Help With PCB Board Assembly Manufacturing?

You know that even one bad joint can cause problems in a full product. This standard helps avoid that. Here’s how it supports your work:

- Training: Your team learns what to do and what to avoid.

- Guidelines: You use the right temperatures, tools, and materials.

- Clear visuals: You compare your work to clear examples.

- Error checks: You catch problems before boards ship.

When your boards leave your shop, you want to know they’ll work. No callbacks, no repairs, just good results.

IPC J Standard Soldering in Real Life

Let’s say you make circuit boards for hearing aids. These boards must be small but work perfectly. If the soldering is poor, the hearing aid may fail. If you follow IPC J-STD-001, you’ll avoid this.

Or maybe you design flight systems. Any failure here could be dangerous. The soldering must be right the first time. IPC helps ensure that.

In both cases, soldering standards give you the rules, and you follow them step by step.

Benefits You Can Count On

Here’s what you gain by using IPC J-STD-001:

- Fewer product failures

- Lower repair costs

- Better customer reviews

- More business opportunities

- Peace of mind

You get stronger, cleaner, longer-lasting joints. That helps your PCBs work better for longer.

Where to Start

If you’re new to IPC J-STD-001, here’s how to begin:

- Read the standard: You can buy it from IPC’s website.

- Take a course: Many schools and companies offer hands-on classes.

- Practice soldering: Use the rules in your daily work.

- Get certified: Show your skills.

- Update your shop: Use the right tools and follow the best processes.

Whether you work alone or in a big team, the steps are the same. The sooner you start, the better your boards will be.

Final Thoughts

Electronic devices are only as strong as their weakest solder joint. With IPC J-STD-001, you build better boards from the start. It helps with training, quality control, and trust. If you work in PCB board assembly manufacturing or want to be the best PCB manufacturer you can be, this standard is for you. Your customers will notice. Your products will last longer. And you’ll sleep better knowing your boards are built right.

Start today, and bring your PCB work to the next level,one solid joint at a time.