When building high-performing electronic devices, getting reliable interconnects is key. One method that makes this possible is wire bonding. It might sound simple, but wire bonding plays a significant role in linking microchips to their packages or circuit boards. Without it, many modern electronics wouldn’t work. If you’re working with any kind of PCB, especially in advanced applications, knowing how wire bonding works can help you choose better solutions and avoid failures.

What Is Wire Bonding?

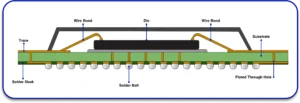

Wire bonding is a way to connect two electronic parts using a skinny wire. It’s used a lot in making integrated circuits (ICs), sensors, and LED packages. A wire bonder machine places a fine wire between a chip and a pad on a PCB or another chip. This wire helps carry electricity between the two points.

If you’re a PCB board manufacturer or use PCB production USA services, wire bonding is something you or your partners may rely on during the PCB manufacturing and assembly process.

Why Is Wire Bonding So Important?

Wire bonding may seem like a small step in PCB production, but it plays a vital role in the overall performance and durability of electronic devices. Here’s why it matters:

1. Reliable Connections

Wire bonding creates stable and clean connections that efficiently transmit electric signals without interference or signal loss. This reliability is crucial for maintaining device functionality over time.

2. Cost-Effective

Compared to other interconnect methods, wire bonding is often more affordable. This makes it an economical choice for manufacturers looking to optimize production costs.

3. Space-Saving

Wire bonding works well in compact designs, allowing for connections in tight spaces where other methods may not fit. This is particularly beneficial in miniaturized and portable electronics.

4. Heat Resistant

Properly bonded wires can withstand higher temperatures compared to other connection methods. This enhances the device’s ability to operate in demanding environments.

When selecting a PCB board manufacturer, it’s essential to ask about their expertise in wire bonding. A well-bonded PCB can make the difference between a long-lasting product and one prone to early failure.

Wire Types: Aluminum vs. Gold

The choice of wire material plays a significant role in the performance and cost of wire bonding. The two most common types are aluminum and gold wires.

1. Aluminum Bonding Wire

Aluminum wires are generally more affordable and work well with wedge bonding techniques. They are commonly used in power devices due to their cost-effectiveness and suitability for high-current applications.

2. Gold Wire for Electronics

Gold wires are more expensive but offer superior performance, especially in ball bonding processes. They resist corrosion and maintain reliable connections over long periods, making them ideal for high-quality and long-lasting devices.

Choosing between aluminum and gold wires depends on factors like cost, strength, and the specific application requirements.

Design Tips for Wire Bonding

To ensure optimal performance and durability of wire-bonded PCBs, consider the following design tips:

- Proper Pad Placement: Arrange bonding pads close to each other and in alignment. This minimizes the length of the wire and reduces stress during bonding.

- Avoid Sharp Corners: Sharp corners can create stress points on the wire, leading to potential cracks or breaks. Smooth and rounded designs are more reliable.

- Maintain Thermal Balance: Wire bonding can be sensitive to temperature. Ensure the board design accounts for heat distribution to prevent overheating during bonding.

- Keep Surfaces Clean: Dust, dirt, or oxidation on bonding pads can weaken the bond. Clean surfaces before bonding to ensure a strong and lasting connection.

Heat Pressure Bonding Services

Heat pressure bonding uses both heat and pressure to form a strong bond. It’s great for making connections that need to last a long time. It’s often used in automotive, aerospace, and medical electronics. These services are sometimes included in complete PCB manufacturing and assembly packages.

If your product will be in a harsh environment, ask your PCB board manufacturer if they offer heat-pressure bonding services. It’s one way to make sure your parts stay connected even under stress.

Benefits of Wire Bonding for PCBs

Wire bonding is a valuable technique used in the production of Printed Circuit Boards (PCBs), especially in the USA. It offers several advantages that can significantly improve the quality and performance of electronic devices. Here are some key benefits:

1. Faster Prototyping

Wire bonding allows for quick and efficient connections, reducing the time needed for prototyping and testing. This helps accelerate the development process and bring products to market faster.

2. Strong Electrical Pathways

Wire bonding creates robust and reliable connections, minimizing the risk of electrical failure. This is crucial for maintaining device performance and longevity.

3. Improved Signal Quality

The smooth and direct connections made through wire bonding help maintain clean and stable signals. This is particularly important in high-frequency and precision applications.

4. Customization Options

Manufacturers can choose from different wire types, sizes, and bonding methods to meet specific requirements. This flexibility makes wire bonding suitable for a wide range of applications, including high-end and compact devices.

Design Tips for Wire Bonding

To ensure optimal performance and durability of wire-bonded PCBs, consider the following design tips:

1. Proper Pad Placement

Arrange bonding pads close to each other and in alignment. This minimizes the length of the wire and reduces stress during bonding.

2. Avoid Sharp Corners

Sharp corners can create stress points on the wire, leading to potential cracks or breaks. Smooth and rounded designs are more reliable.

3. Maintain Thermal Balance

Wire bonding can be sensitive to temperature. Ensure the board design accounts for heat distribution to prevent overheating during bonding.

4. Keep Surfaces Clean

Dust, dirt, or oxidation on bonding pads can weaken the bond. Clean surfaces before bonding to ensure a strong and lasting connection.

Talk to your PCB manufacturing and assembly team about these before finalizing your board layout.

When to Use Wire Bonding

You might want to consider wire bonding when:

- You’re building very small or sensitive devices.

- You need custom bonding setups.

- You want strong, long-lasting connections.

- Your design needs fast signal transfer.

It’s used in smartphones, LED lighting, solar panels, and even satellites.

Conclusion

Wire bonding may be a small part of electronics production, but it makes a big difference. It keeps your devices running smoothly and helps your circuits last longer. Whether you use wedge bonding, bonding cables, or heat pressure bonding services, picking the right wire and method is key. If you’re working with a PCB board manufacturer or looking for PCB production USA options, make sure they offer quality bonding services. With the right wire bonding approach, your PCB manufacturing and assembly process becomes more reliable, more efficient, and more advanced.