Modern electronics cannot do without flexible and rigid-flex PCBs as they are lightweight and help save space in an increasingly complex environment. But, in order to perform at their best, these circuits need mechanical support to maintain their structure’s integrity. This is where PCB stiffeners come in. They provide stability, enhance component mounting, and aid in the mechanical robustness of flex circuit board manufacturers and flexible printed circuit manufacturers.

What is a Stiffener in a Flex PCB?

A PCB stiffener is an additional support structure applied to a flex PCB connector to provide mechanical reinforcement. Flexible circuits can bend and twist, making them different from traditional Rigid Boards. Stiffeners are used to strengthen specific geometrical areas on the board’s surface, particularly the zone where components are mounted, or connectors are inserted.

Key Purposes of PCB Stiffeners

- Reduce strain on flexible circuits brought about by extreme bending.

- Support the mounting of electronic components through the creation of stable surfaces.

- Provides support on areas with connectors to enhance interconnections.

- Enhance the assembly processes through circuit shape retention.

- Eliminate mechanical strain that jeopardizes the integrity of solder joints.

What Is the Importance of Stiffeners in Flex PCBs?

Flexible PCBs with specific functional areas designed to be rigid, such as housing electronic elements, connectors, or solder joints, need to be stiffened, aiding the assembly and reliability of flex circuits. Stiffeners help with the assembly and reliability of flex circuits by:

- Providing mechanical strength to critical areas.

- Assuring high-density component placement.

- Reducing the chances of flexing or damaging during handling and operation.

- Decrease the thermal fatigue on solder joints and vias.

- Enhancing heat dissipation efficiency for more significant power requirements.

Types of Stiffeners Used In PCB

The choice of materials to fabricate stiffeners depends on the application and the level of support needed. There are most commonly used types of stiffeners include:

- Polyimide Stiffeners

- Used to provide lightweight support.

- Allows for ease of bending while stiffening in certain areas.

- Used in applications where moderate support is needed.

FR-4 Stiffeners

- Manufactured using the same material as standard PCB substrates.

- Allows for structure and supports the stiffeners.

- Utilized as needed additional structural support to aid component mounting.

- Aluminum and Stainless Steel Stiffeners

- Very effective in conducting heat and has good structural strength.

- Ideal for use in applications with excellent mechanical stability.

- Used for high-power electronics to control thermal expansion.

DtandardStiffener Thicknesses

- The appropriate level of support and application determines how thick the stiffener would be. Some standard thicknesses are:

- 0.2mm to 0.5mm for less stiffened areas.

- 0.8mm to 1.6mm for moderate stiffened and rigid areas.

- Designed for demanding applications where maximum weight support is needed, a board with 2.0mm thickness capabilities.

How are Stiffeners Used on PCB?

1. Placement Disposition

Stiffeners are required at places that need mechanical reinforcement, such as connectors, mounting zones for components, and soldering sections. Together, they include:

- Connector Areas: Minimizes flexural strains of flex PCB connector interfaces.

- Component Mounting Zones: Resists flexural sagging on the PCB due to heavy components.

- Soldering Sections: Acts as a substrate for connecting surfaces soldering.

- Stress Points: Help reduce the overexertion of force on essential flexural areas.

2. Attachment Techniques

PCB Stiffeners are attached using:

- Adhesives: Epon glue is mainly used for polyimide stiffeners.

- Mechanical Fastening: Rigid polyimide stiffeners can also be supplied with screw or rivet holes for easy attachment.

- Lamination: Permanent attachment is done through lamination in situations that require high reliability.

Comparison Between Rigid-Flex PCBs And Rigidized PCBs

Even though both rigidized PCBs and Rigid-Flex PCBs incorporate stiffeners, their usages differ.

Rigid-Flex PCBs: These boards have stiff and flexible sections combined into a singular structure.

Rigidized PCBs: These boards are flexible PCBs with Stiffeners that are Reinforced but are not entirely rigid.

Important Factors Variating PCB Stiffener Considerations

When stiffeners are involved in the design process of a PCB, some factors that affect the structure include:

Material Specification: Use materials that satisfy the mechanical and thermal requirements.

Thickness: Provide proper support for the stiffener with a svelte outline to prevent unnecessary bulk.

Attachment Method: Use an optimal adhesive or a mechanical method to provide good bonding.

Manufacturing Limitations: Design compliance must be adhered to with the manufacturers of flexible printed circuits.

Learn About: Air Gap Construction Enhances Flexibility in Rigid-Flex PCBs

Benefits of Implementing PCB Stiffeners

Increased Structure Strength: Reduces overbending that can destroy parts.

Improved Component Placement: Allows for a platform in which efficient soldering and assembly can occur.

Connector Reliability Improvement: Lowers the tension on the solder joint and interconnects.

Better Management of Heat: Assists in heat removal during intense power situations.

Improved Component Handling and Assembly: Eases the handling of flexible circuits during the manufacturing process.

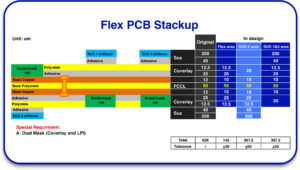

Illustration Rigid-Flex Stackup with Stiffeners

A common example of a rigid-flex stack-up with stiffeners consists of the following:

Level 1: Flexible polyimide circuit layer.

Level 2: Adhesive for the stiffener.

Level 3: FR-4 stiffather to strengthen core regions.

Level 4: Extra adhesive to ensure no loss of attachment.

Level 5: Final flex layer for flexibility.

Conclusion

Stiffeners are key to the stiffness and longevity of useable flexible and rigid-flex circuits. They offer mechanical rigidity, increased component placement accuracy, and guaranteed reliable interconnects in high-stress situations.

Proper stiffener material selection and placement can be achieved by cooperating with professional flex circuit board manufacturers and flexible printed circuit manufacturers. If you’re in search of quality circuit board stiffener solutions for your next project, reach out to an experienced manufacturer to share your needs and obtain a custom-fit solution.

I simply couldn’t leave your site before suggesting that I extremely loved the usual information a person supply for your guests? Is gonna be back often to check out new posts.