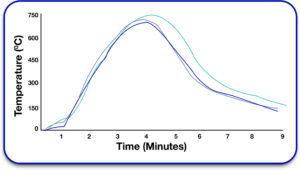

A thermal profile is a graphical representation of the temperatures that are set when applying heat to a printed circuit board (PCB), especially during reflow soldering. For engineers, it is a way to measure the range of temperatures and their effectiveness on the soldering process and the PCB’s components.

Thermal profiles also capture essential information like overtemperature, the cooling phase, and ramp rates. A well-designed thermal profile is critical for reliably and steadily defect-free assemblies in PCB manufacturing.

How Thermal Profiling Helps Manufacturers Build Perfect PCBAs

With the help of software engineers, thermal profiles are an essential aspect in ensuring there is a high level of quality of produced PCB assemblies. Let us look at the advantages of thermal profiling in PCB board assembly manufacturing:

- Prevents Damage of Components: During soldering, components are not overheated to ensure that they are not damaged.

- Improves Reliability of Solder Joints: A specific and accurate thermal profile produces reliable solder joints that are unlikely to be faulty.

- Reduces Defect Rates: Cold solder joints, warping of components, and delamination are greatly reduced.

- Optimizes Speed of Production: Profiling correctly means a well-defined process that eliminates the waste of correcting mistakes and fastens the rate of production.

- Staying on Specifications: Controlled soldering temperatures for circuit boards allow manufacturers to comply with industry standards.

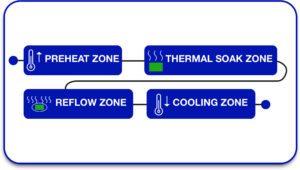

4 Steps in Temperature Profiling

The entire thermal profile of a PCB board assembly is usually broken down into four main steps:

1. Preheat Stage

To prevent thermal shock, the PCB is warmed up gradually.

PCBs ramp up around 1–3 degrees Celsius every second.

2. Soak Stage

The PCBs are evenly heated to prepare them for soldering.

This phase is also helpful for contaminant removal and flux activation.

3. Reflow Stage

The PCB is brought to the peak soldering temperature between 220 to 240 degrees Celsius, which varies based on the solder paste component.

Strong and durable solder joints are made with the components.

4. Cooling Stage

Careful cooling allows the solidification of joints without fracture or stress.

Changes to Thermal Profiles

Many PCB fabricators have adopted these two profiles with the assumption of the standard assembly process:

Ramp-Soak-Spike (RSS) Profile:

The temperature is elevated during soaking. This profile is best suited for complicated boards with multiple components.

Ramp-to-Spike (RTS) Profile:

The temperature is raised continuously to the peak solder temperature. This profile is most compatible with uniform, simple boards.

Instructions On How To Make a Thermal Profile On a Reflow Oven

1. Prepare the Reflow Oven

Make sure that the oven is clean and calibrated.

2. Insert Thermocouples

Attach thermocouples to the large components. As well as the corners of the PCB.

3. Choose Initial Settings

At the beginning, set parameters based on the solder paste manufacturer’s instructions.

4. Run Profiles Tests

Adjust ramp rates and peak temperatures by running tests. Preferably multiple tests.

5. Analyze the Data

Check the temperature graph for proper, consistent heating and cooling.

6. Optimize Settings

In regard to the collected data, adjust the settings to achieve a stable thermal profile.

7. Everlap Solder Joints

Check the quality of solder joints.

What Sets Some PCB Manufacturers Apart Concerning Thermal Profiling

- Invest In Accurate Thermocouples: Ensure that they are fastened well to yield precise results.

- Have Multiple Monitors: Have the capability to check the temperature of different locations of the PCB.

- Solder Paste Temperature Recommendations: Do not forget to follow the temperature recommendations when soldering PCBs.

- Threshold Ramp Rates: Do not make temperature jumps. Always make it gradual to avoid thermal shock.

- Oven Cleaning Schedule: Maintain the reflow oven regularly by cleaning, calibrating, and servicing it.

- Profile Records: Document them for quality control purposes.

- Use Profiling Software: Collect and analyze the data without manual labor.

- Fee Test Profile Consistency: Seek a minimum for the number of profiles that pass the uniformity test.

- Explain To Operators: Give enough information to people about thermal profiling techniques.

Profiling via Software as Compared to Manual Temperature Profiling

Manual Profiling

- Uses physical analysis by thermocouples and operators.

- A time-consuming process but is affordable with fewer numbers.

Software-Driven Profiling

- Collects and analyzes data automatically.

- Grants faster adjustments and real-time views.

- Most efficient in manufacturing PCB board assembly in bulk.

Transforming PCB Assembly with Virtual Profiling Technology

A style of virtual thermal profiling is a technique that uses an algorithm to predict heat flow in a PCB and does not require physical testing. Because of this, it improves the speed of creating specific thermal profiles.

Important Aspects of Virtual Profiling

- Simulated Run Testing: No need for test runners for test simulations.

- Quick Changes: Makes the optimization process faster.

- Arguably Comprehensive: Analyzes deeper for more data-driven insights that cover more.

How Blind Buried Circuits Derives Custom Thermal Profiles

Blind Buried Circuits is reputed to provide advanced thermal profiling for PCB technology and assembly as well as specializes in meeting client specifications:

- Customized Profiling: We design thermal profiles for specific required projects.

- We have the latest technology: Our reflow ovens and other tools help in achieving the set goals.

- PCB assembly expertise: High proficiency in solder temp optimization for circuit boards.

- Quality Focused: IPC standards and best practices are followed for guaranteed performance.

The quality of the manufactured PCB assemblies relies directly on the level of reliability and expertise used in providing thermal profiling. Understanding its types and stages makes it easier for manufacturers to design products of higher value. Blind Buried Circuits uses modern technology and skill to provide your business with high-precision thermal profiling services designed according to your specifications. Looking to make changes in your PCB assembly process? Speak to Blind Buried Circuits about how our specialized thermal profiling services can transform your work.