The world of electronics, which includes smartphones and industrial machines, is all-encompassed in PCBs (Printed Circuit Boards) that circulate signals such as power. Unfortunately, even the most advanced designs have signal problems that can hamper performance.

If you’re a PCB board producer, engineer, or technician, resolving these issues is paramount to ensuring electronic devices are reliable and practical. In this blog, we will take a look at common problems regarding PCB signals, what causes them, and how to solve them. We will also look at how the industry leading PCB board manufacturer, Blind Buried Circuits, can help with LCD circuit board repair and PCB repair to ensure your device’s performance is optimum.

Common PCB Signal Problems and Their Sources

The overall integrity of PCB signals is known as signal integrity, and this is one of the basic functional components of a PCB. Compromised signals can lead to data errors, device malfunctions, or system failures. Hence, imperative signal issues related to PCBs are as follows.

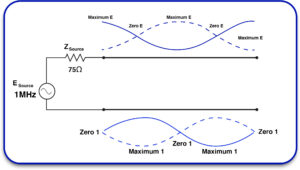

1. Signal Reflection

As a moving signal bounces back to where it traveled due to an imbalance in impedance, signal reflection occurs. This distorts the original signal and corrupts data. Such issues are common due to inadequate termination, routing of traces in the wrong manner, and undetermined connectors.

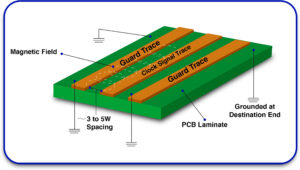

2. Crosstalk

Crosstalk occurs when an adjacent trace interferes with the functioning of another trace or vice versa. This usually happens when there is insufficient spacing or shielding. Such interference is far worse in high or dense-speed PCBs because the placement of the traces is very close.

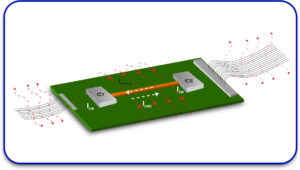

3. Electromagnetic Interference (EMI)

Signals tend to get disrupted when external electromagnetic waves come in contact with electronic devices. Such issues are related to low-quality shielding, components placed in nonstandard positions, or insufficient grounding.

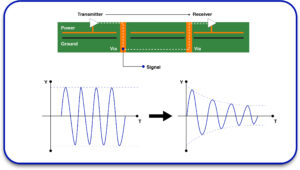

4. Signal Attenuation

This refers to the reduction in signals when the strength is traveling through a PCB. It can be caused by inadequate power supply, heightened resistance materials, or long trace lengths.

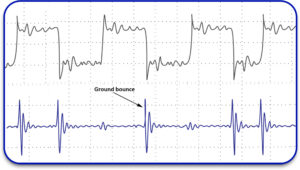

5. Ground Bounce

Ground bounce occurs as a result of high-speed switching signals, where a certain change to the voltage level reference to the ground occurs. Erroneous triggering of logic circuits may occur, and device operation may become chaotic.

Tool and Techniques for Diagnostic Troubleshooting Signal Problems on PCB

Repairing or fixing a problem with a PCB requires the use of the most reliable Tools and Techniques of Diagnostic Troubleshooting Signal Problems on PCB. These include, but are not limited to, the following:

1. Impedance Matching

The process of controlled impedance routing or the use of appropriate termination resistors permits the minimization of reflections and signal distortion that result from crosstalk, consequently improving the transmission of high-speed signals.

2. Trace Optimization

Vertical and horizontal spacing of circuits is crucial to reduce the effects of crosstalk. Other trace routing techniques, such as not running identical traces parallel over long distances and using differential signaling can assist in enhanced noise immunity.

3. EMI Mitigation

EMI can be minimized by implementing proper grounding strategies, such as having a solid ground plane and low wire loops around grounds, and shielding sensitive components and traces to reduce interference.

4. Signal Integrity Analysis

Certain simulation tools should be used to analyze the design and verify signal integrity during the design stage. SPICE or other useful tools for PCB design can identify issues on the schematic long before the board is produced.

5. Power Supply Design

When designing the power supply, ensure that it can sufficiently fulfill the PCB’s power requirements. Place decoupling capacitors close to delicate components to minimize noise and improve the power supply’s stability.

6. Testing and Debugging

Post-manufacturing, the PCB should be thoroughly analyzed with oscilloscopes, spectrum analyzers, and TDRs. These instruments will assist in identifying signal problems and check whether the corrective actions taken produce the desired results.

Learn About: The Critical Methods in PCB Testing and Inspection

The Role of a Reliable PCB Board Manufacturer

While corrective action does work, it is often best to approach a problem from a preventative angle. Working with reputable PCB board manufacturers, such as Blind Buried Circuits CLC, will mitigate most issues related to signal integrity problems from the onset. Here’s how

1. Expert Design Support

Our team of designers and engineers with good track records will help with the PCB design and address signal integrity issues through proper impedance matching and trace routing. This provides assurance that the PCBs will function as required.

2. Advanced Manufacturing Techniques

To manufacture the PCBs, we rely on advanced equipment, which allows us to obtain high precision and low defects. In addition, providing a complete set of equipment and strict quality control procedures allows us to satisfy all the requirements for each board.

3. Thorough Testing

Blind Buried Circuits does not stop at creating PCBs. Our rigorous testing procedures guarantee complete performance fulfillment according to customers’ specifications. Some of our methodologies are signal integrity review, EMI inspection, functional examination, and many others that help us rectify possible defects prior to delivering the products to the customers.

Even with quality design and manufacturing executions, PCBs are susceptible to multiple concerns due to aging, environmental stress, or component failure. Blind Buried Circuits takes pride in being a leader in circuit board repair, and here is how we can help:

4. Preventative Maintenance

Routine maintenance can avoid signal problems and extend the life of PCBs. We provide preventative maintenance services to ensure your boards remain in peak condition.

Why Choose Blind Buried Circuits for PCB Repair?

Blind Buried Circuits is a PCB repair service that can be trusted for various reasons. Let us enlighten you:

- Expertise: We employ technicians capable of identifying and fixing multiple issues with a circuit board in the shortest amount of time possible.

- State-of-the-Art Facilities: We carry out repairs with high precision and dependability, utilizing the latest tools and machinery.

- Customer-Centric Approach: We always give clients’ needs our primary attention, enabling us to offer the best possible solutions.

- Quick Turn Around: Minimizing downtime is essential, so we focus on providing efficient and rapid repair services.

The ability to troubleshoot signal problems in a PCB is integral to the reliability of electronic devices. More importantly, understanding issues such as signal reflection and EMI crosstalk and coming up with viable solutions is a key step in solving signal integrity issues.

Prevention and timely repairs are both equally important. By collaborating with a reputable PCB board manufacturer such as Blind Buried Circuits, you can sidestep signal problems from the very beginning. In addition, our professional services for circuit board repair and PCB repairs guarantee that your boards are well maintained throughout their lifecycle.

Do you have signal problems with your PCBs? Don’t let them interrupt your business processes. Contact Blind Buried Circuits today for professional diagnostics, repairs, and preventive maintenance. We are here to help you achieve perfect signal integrity and enhance the performance of your electronic devices.