Printed Circuit Boards, or PCBs, are the foundation of most electronic devices. They connect and support components in gadgets, appliances, computers, and machines. A key part of a PCB is the material it is made of. One material that is commonly used and trusted is called FR4. You might be wondering why FR4 is chosen so often. If you are someone working with electronics or thinking about Custom PCB manufacturing, understanding FR4 will help you make better choices.

What is FR4 Material?

FR4 is a type of fiberglass-reinforced epoxy laminate. The name “FR” stands for “Flame Retardant,” and the number “4” indicates the grade. It is one of the most widely used materials in the PCB world. FR4 circuit board materials are strong, lightweight, and resist moisture and heat. Because of these qualities, it works well in many electronic applications.

Why Is FR4 So Common in PCBs?

There are several reasons why most PCB manufacturers choose FR4. First, it offers great strength without being too heavy. That makes it a good fit for both small and large devices. Second, its ability to handle heat and resist fire makes it safe and reliable. You want your electronics to work properly without the risk of overheating or catching fire.

Also, FR4 has a good electrical insulating property. It keeps electrical currents from jumping from one trace to another, which is important in all kinds of circuits. This helps keep your devices running smoothly.

The Role of FR4 in PCB Fabrication USA

If you are looking for PCB fabrication in the USA, most companies will offer FR4 as a standard material. That’s because it is affordable and performs well. Whether you’re creating simple circuits or complex multi-layer boards, FR4 boards can handle the job. They are also easy to cut and shape, which helps speed up the manufacturing process.

FR4 Dielectric Constant: What It Means for You

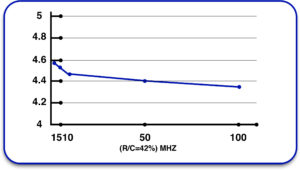

The dielectric constant (or Dk) of a material shows how well it stores electrical energy. For FR4, the dielectric constant is typically around 4.5. Why does this matter? It affects how signals move through the board. A stable dielectric constant helps with signal integrity. If you’re designing circuits where timing and signal clarity matter, like in computers or communication devices, FR4 is a smart choice.

Handling PCB Delamination and Crazing

Two common problems in PCB manufacturing are delamination and crazing. PCB delamination happens when layers of the board separate. Crazing in PCB refers to tiny cracks in the fiberglass weave. Both problems can make your board less reliable.

FR4 helps reduce the chances of these issues. Thanks to its heat resistance and strong bond between layers, it can hold up during soldering and other manufacturing steps. However, proper storage and careful manufacturing steps are still needed. Even the best material can fail if not handled correctly.

Comparing FR4 with Other Materials

While FR4 is popular, it’s not the only material out there. High-frequency boards might use materials like Rogers, which offer lower dielectric loss. But these materials are more expensive. For general use, FR4 offers a solid balance between cost and performance.

Some boards that go into flexible devices may use other materials, especially in devices that bend or fold. But for most rigid boards, especially in Custom PCB manufacturing, FR4 remains the go-to material.

1. Cost and Availability

FR4 is easy to find and relatively low in cost. That makes it ideal for projects from student experiments to large industrial orders. If you are a small business or startup, working with a PCB manufacturer that uses FR4 can help you save money without cutting corners.

2. FR4 and Environmental Factors

Another reason FR4 is widely used is that it holds up well in many environments. It can handle moisture, dust, and heat. If your electronics will be used outdoors or in harsh conditions, FR4 is a solid option. Some FR4 boards are even treated to resist chemicals, making them useful in lab and factory settings.

Choosing the Right PCB Manufacturer

When selecting a PCB manufacturer, ask about the materials they use. A reliable manufacturer will explain why they choose FR4 and how it meets your needs. Some companies that specialize in PCB fabrication in the USA offer advanced options, like different FR4 thicknesses or flame-resistant grades.

Good manufacturers also help with testing to avoid issues like PCB delamination or crazing. Look for companies that provide full PCB manufacturing and assembly services, so your board is tested and ready to use.

What Makes a Good FR4 Board?

A good FR4 board has a uniform surface, strong layers, and clear copper traces. You should not see any bubbles, warping, or cracks. Boards should pass standard tests to ensure they are safe and perform as expected.

If you work with custom designs, ask your PCB manufacturer about custom PCB manufacturing with FR4. They should be able to match your design needs, from shape and layer count to copper weight and surface finishes.

Practical Tips for Your PCB Project

Here are a few helpful steps to get better results with FR4:

- Always use a proper design layout to prevent hot spots.

- Avoid sharp corners in copper traces to reduce stress.

- Choose the right copper weight based on how much current your board will handle.

- Double-check your design to make sure the dielectric constant of FR4 fits your signal needs.

- Store your FR4 boards in a dry place to prevent moisture buildup.

Final Thoughts

FR4 is a trusted material for a reason. It is strong, affordable, and safe. It works well in many types of electronics, from toys and gadgets to medical tools and computers. Whether you are just starting out or working on a high-end product, FR4 circuit board materials offer a reliable base.

By understanding the properties of FR4 and working with a skilled PCB manufacturer, you can avoid problems like PCB delamination and crazing. This helps you build better products that last longer and perform better. And if you ever need special features, Custom PCB manufacturing gives you the freedom to create a board that fits your exact needs.

Always choose a manufacturer that knows the value of FR4 and has experience with PCB fabrication USA services. That way, you get the best mix of quality and price, no matter the size of your project.