When developing a printed circuit board (PCB), accurate component data is critical for the development process to be as seamless as possible. Everything relies on high-quality data. In the absence of well-structured libraries, you run the risk of facing errors in design, mismatches, or even incomplete manufacturing of the board. For flex-rigid PCB manufacturers and rigid-flex PCB manufacturers, reliable and complete PCB libraries will improve production efficiency and reliability in the long term.

This blog will discuss the importance of PCB libraries, explain PCB library management, and explain how to create PCB libraries that improve design workflow.

What Is A PCB Library?

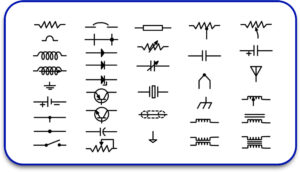

A PCB library is a digital catalog of components and footprints that a designer requires while working on a circuit board layout. The catalog consists of:

- Schematic Symbols: Graphical representation of a component in a circuit diagram.

- PCB Footprints: The layout of a component on a given board.

- Three-Dimensional Models: Contribute to understanding how a component would fit within a product.

- Electrical Parameters: Contains essential components such as pin configuration, tolerances, signal ratings, and others associated with being fused in one.

When an organized PCB library is in place, designers will no longer need to create them from scratch, which saves time and minimizes the chances of making errors.

The Importance of Outstanding PCB Libraries:

1. Guarantees an Accurate Design

An improperly handled PCB component library can result in footprint errors, wrong pin locations, or absence of traces. All of these can result in improper board function and increased production time.

- High-quality PCB libraries ensure that:

- The prints and pin names of the parts are correct.

- Electrical characteristics are relevant to the actual devices.

- Mistakes in design that affect the reliability of the PCB are increased in number.

2. Streamlining the Design Process

It’s very tedious to create and confirm parts for each project. A high-quality PCB library allows component reuse, making development.

- Symbols and footprints provided academically can replace a lot of manually drawn ones.

- Quicker selection of parts leads to quicker completion of the design.

- Reduced number of designs means it’s easier to build a prototype.

3. Minimizing Errors In Production

Mistakes in PCB footprints or schematic symbols may create very costly manufacturing errors. In preparing the PCB library, all components must conform to defined quality standards, lessening these expenses.

- Guarantees that parts are properly loaded.

- Precludes wrong sizes or spacing of drill holes.

- Assists in allowing flex-rigid PCB manufacturers to produce high-density topology PCBs.

4. Improves the Coordination Among Teams

In the case of firms that employ large numbers of designers and engineers, an Organization of Centralized Management system ensures:

- There is a uniform component across all files.

- Increased interaction between the design team and the production team.

- For changes or updates, troubleshooting processes can happen at a faster rate.

5. Advanced PCB Designs

Containing well-maintained PCB component libraries, designers can work on complex and high-speed electronics with:

- High-speed signal routing with controlled impedance.

- Rigid-flex and multi-layer PCB designs.

- Footprints that are optimized for automated assembly processes.

Best Practices for Organizing a PCB Library

1. Standardization

- Use standardized formats to maintain a constant quality of design in your PCB libraries.

- Adhere to IPC standards for footprints (IPC-7351).

- Use standardized component names.

- Create a standard format that can be used across several EDA tools.

2. Component Verification

- Before verifying a component in your PCB libraries, make sure:

- The schematic symbol and its corresponding pin and footprint dimensions are correct.

- The manufacturer’s specifications and datasheets are accurate.

3. Model Updates

In order to remain compatible with new methods of manufacturing as well as prevent obsolete components from being used, frequent updates are needed.

- Remove obsolete components.

- Models that comply with newer industry standards should be added.

- Update the footprint check using the manufacturer’s datasheets.

4. Categorization of Libraries

Effective management of PCB libraries can be achieved when they are organized based on:

- Types of components ( Resistors, capacitors, ICs, connectors).

- Manufacturing types- flex, rigid-flex, or standard PCBs.

- Components specific for an application- power electronics, high frequency.

5. Library Management Automation

Improved error detection and consistency can be achieved with automated library tools.

- Software used for library management can provide updates instantly.

- Automated tools for rule checking can identify an incorrect footprint.

- Teams can access cloud-based libraries instantly.

How to Build Quality Libraries for PCB Designs

Step 1: Compile Information on the Suppliers

- Compile datasheets and definitions for all parts.

- Check all values, including their sizes and the electrical attributes.

Step 2: Draw Symbols for the Schematics

- All symbols must comply with the relevant drawings.

- Clearly identify pin names and numbers.

Step 3: Create Footprints for the PCB

- Measurements must be carefully taken to ensure they comply with the guidelines of the manufacturer.

- Solder mask and silkscreen layers must be added for clarity.

Step 4: Check the Validity of the Library

- Design rule queries need to DRC errors.

- Use test placements in PCB layout packages.

Step 5: Save to a Single Location

- A cloud-based repository allows collaboration within the team.

- Changes should continuously be tracked so that there is a clear audit trail.

Errors You Should Not Make In the Management of PCB Libraries

1. Incorporating the Wrong Footprints

- Assembly will fail for incorrect matching footprints.

- Make it a point to always check footprints against the manufacturers’ specifications.

2. Do Not Adhere to Any Useable Standards

- Competitors might find it challenging to use out-of-the-box, non-standard dimensions.

- Comply with IPC standards for footprint design.

3. Failing to Delete Components That Are No Longer Used

- Some parts are simply deleted or replaced.

- Audit and update your library frequently.

4. Cluttered Libraries

- Selecting parts and components becomes challenging because of a haphazard arrangement of libraries.

- Organize libraries or components to enable quick selection.

Why Choose Blind Buried Circuits?

At Blind Buried Circuits, we custom-manufacture PCBs and provide rigid-flex PCB services with high-quality PCB libraries that meet all standards.

- Accurate libraries for components enable accurate design of the PCBs.

- Provided expert attention regarding the development of PCB libraries that aid in functional designs.

- Advanced flexibility in the manufacturing of PCBs and rigid-flexed PCBs.

If your need is efficient management of PCB library and fabrication of flexible PCBs, get in touch and let us help you with your next PCB project.

Maintaining high-quality PCB libraries ensures efficiency in the PCB design process, accuracy, and elimination of unwanted errors while in the design stage. Whether it is RF or rigid-flex PCBs, flexible circuits, or high-speed designs, having checked and defined libraries assists in achieving better design. You can eliminate the mistakes committed while designing and facilitate the speed of production by adhering to the best practices of documentation and using standard footprints along with keeping the libraries current. Flex rigid PCB manufacturers aiming to enhance the workflow of PCB design should consider investing in good rigid PCB component libraries for better-optimized results.

Need help with the management of the PCB library? Let’s talk about your project today!