Wireless technology is changing the world around us. From smart homes to industrial automation, the Internet of Things (IoT) is everywhere. But what really powers this revolution? The answer is smart, flexible, and reliable printed circuit boards (PCBs). At Blind Buried Circuits, we understand how the right PCB design can make or break your wireless project. In this blog, you’ll learn how innovations in Custom PCB manufacturing, flexible boards, and advanced design are fueling IoT growth, especially as 5G and industrial IoT take center stage.

Why Wireless Communication in IoT Needs Better PCBs

Wireless devices are at the heart of IoT. They need to send and receive data quickly, reliably, and with low power. This is only possible with a PCB that’s designed for wireless communication. If you’re building a device for smart homes, factories, or cities, your PCB for IoT must:

- Support high-speed data transfer

- Handle multiple wireless standards (Wi-Fi, Bluetooth, 5G)

- Be small and energy-efficient

- Resist interference from other electronics

A top-notch PCB manufacturer will help you meet these needs with the latest technology and materials.

The Rise of Rigid Flex PCB Manufacturer Solutions

Traditional rigid PCBs are great, but today’s IoT devices often need something more. Enter the rigid-flex PCB manufacturer. Rigid-flex PCBs combine the strength of rigid boards with the flexibility of thin, bendable circuits. This allows you to:

- Fit PCBs into tight or oddly shaped spaces

- Reduce the number of connectors and cables

- Improve durability in devices that move or vibrate

- Lower the risk of signal loss and interference

From wearables to industrial sensors, rigid-flex PCBs are becoming the standard for advanced IoT products.

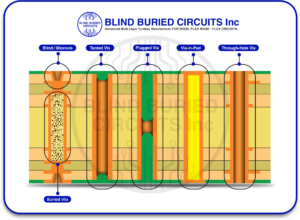

Miniaturization and High-Density Interconnects (HDI) in IoT PCB Design

IoT devices are getting smaller but more powerful. This means your IoT PCB design must pack more features into less space. High-Density Interconnect (HDI) technology is the answer. HDI allows for:

- More connections in a smaller area

- Shorter trace lengths for faster signals

- Better performance with less power

HDI is now common in smartphones, medical devices, and especially IoT sensors that need to be tiny but smart.

Custom PCB Manufacturing for Wireless Systems

Every IoT project is unique. Off-the-shelf PCBs rarely offer the right fit. That’s why Custom PCB manufacturing is so important. With custom boards, you can:

- Choose the best materials for your wireless needs

- Design the perfect stack-up for your signals

- Add special features like antennas, sensors, or shielding

- Optimize for low power and high reliability

A skilled PCB manufacturer will guide you through the process, from design to production, ensuring your board supports all your wireless goals.

5G and the Future: Internet of Things IoT in 5G Wireless Communications

5G is more than just faster internet for your phone. It’s a game changer for IoT. With speeds up to 20 Gbps and ultra-low latency, 5G lets IoT devices:

- Share data in real-time

- Connect millions of devices at once

- Work reliably in busy, noisy environments

But 5G also brings new challenges for PCB design. High-frequency signals need careful routing, shielding, and material choices to avoid signal loss and interference. The best PCB for it is designed from the start to handle these demands.

Industrial IoT Growth: Smart Factories and Connected Machines

The industrial world is embracing IoT like never before. In factories, warehouses, and energy plants, connected sensors and machines are making work safer, faster, and more efficient. This industrial iOt growth depends on PCBs that can:

- Survive harsh conditions (heat, vibration, dust)

- Handle wireless protocols like Zigbee, LoRa, or 5G

- Support real-time monitoring and predictive maintenance

Custom PCB manufacturing is key here. You need boards that are tough, reliable, and built for your exact needs.

IoT PCB Design: Best Practices for Wireless Success

If you want your IoT device to perform well, follow these iot PCB design tips:

- Plan for wireless: Place antennas away from noisy components and use ground planes for shielding.

- Choose the right materials: Some materials handle high-frequency signals better than others.

- Keep traces short: Shorter traces mean less signal loss, especially at high speeds.

- Use proper shielding: Protect sensitive parts from outside interference.

- Test, test, test: Work with a pcb manufacturer who offers full testing for wireless performance.

PCB for IoT: What to Ask Your Manufacturer

When you’re ready to build your next IoT device, ask your PCB manufacturer these questions:

- Can you make rigid-flex PCBs for my wireless project?

- What experience do you have with HDI and miniaturized designs?

- How do you handle signal integrity for 5G and high-frequency applications?

- What testing do you offer for wireless communication in IoT?

- Can you help with custom antennas or RF features?

How Blind Buried Circuits Support Wireless IoT Growth

At Blind Buried Circuits, we’re committed to helping you succeed in the fast-moving IoT world. Here’s how we support your wireless projects:

- Expertise in rigid, flex, and rigid-flex PCBs

- Advanced HDI and miniaturization for compact devices

- Custom stack-ups and material choices for wireless performance

- Full design support for antennas, sensors, and RF shielding

- Testing and quality control for every board

Whether you’re building a smart sensor, wearable, or industrial controller, we have the skills and technology to bring your ideas to life.

Key PCB Innovations Driving IoT Growth

| Innovation | Benefit for IoT Devices | Example Use Case |

| Rigid-Flex PCBs | Fit in tight spaces, durable | Wearables, medical sensors |

| HDI Technology | More features in less space | Smart home sensors, trackers |

| Custom Manufacturing | Tailored for wireless needs | Industrial gateways, smart meters |

| 5G-Ready Design | Fast, reliable connections | Factory robots, real-time video |

| Advanced Materials | Better signal integrity | 5G routers, remote monitoring |

Final Thoughts

Wireless systems are the backbone of the IoT revolution. With the proper PCB manufacturer and a focus on advanced design, you can unlock new possibilities for smart devices, industrial automation, and 5G-powered solutions. Blind Buried Circuits is ready to help you with Custom PCB manufacturing, rigid-flex solutions, and all your wireless needs. Let’s build the future of IoT together, one smart board at a time.

Frequently Asked Questions (FAQs)

Q1: Why is rigid-flex PCB manufacturer expertise essential for IoT?

Rigid-flex PCBs allow you to fit boards into small or unusual shapes, making them perfect for wearables and space-limited devices. They also reduce failure points by cutting down on connectors and cables.

Q2: How does 5G affect PCB for IoT design?

5G brings much faster data speeds and lower latency, but it also requires careful PCB design to avoid signal loss and interference. Material choice, trace layout, and shielding are more important than ever.

Q3: What are the main benefits of custom PCB manufacturing for wireless systems?

Custom PCB manufacturing lets you optimize your board for wireless performance, add special features like antennas, and ensure your device meets all its requirements for size, power, and reliability.

Q4: How does industrial IoT growth impact PCB manufacturing?

Industrial IoT demands tougher, more reliable PCBs that can handle harsh environments and support real-time wireless communication. Manufacturers must offer advanced testing and rugged designs.

Q5: What is the role of HDI in IoT PCB design?

HDI technology allows more connections in less space, helping IoT devices stay small and power efficient while adding more features and better performance.

Q6: Can Blind Buried Circuits help with wireless communication in IoT?

Yes, we offer full support for wireless PCB design, including antenna placement, RF shielding, and testing for all major wireless standards.

Q7: What should I look for in a PCB manufacturer for IoT projects?

Look for experience with rigid-flex and HDI, a track record in wireless and 5G projects, and strong support for custom design and testing.

Q8: How does IoT in 5G wireless communications change the future of electronics?

5G allows real-time, high-speed connections for millions of devices, opening up new possibilities for smart cities, factories, and healthcare. It also raises the bar for PCB design and manufacturing.